UV-cured white curtaining paint and preparation method thereof

A technique of flow coating and coating, which is applied in the direction of coating, etc., to achieve the effect of good deep curing, good fullness and excellent hiding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

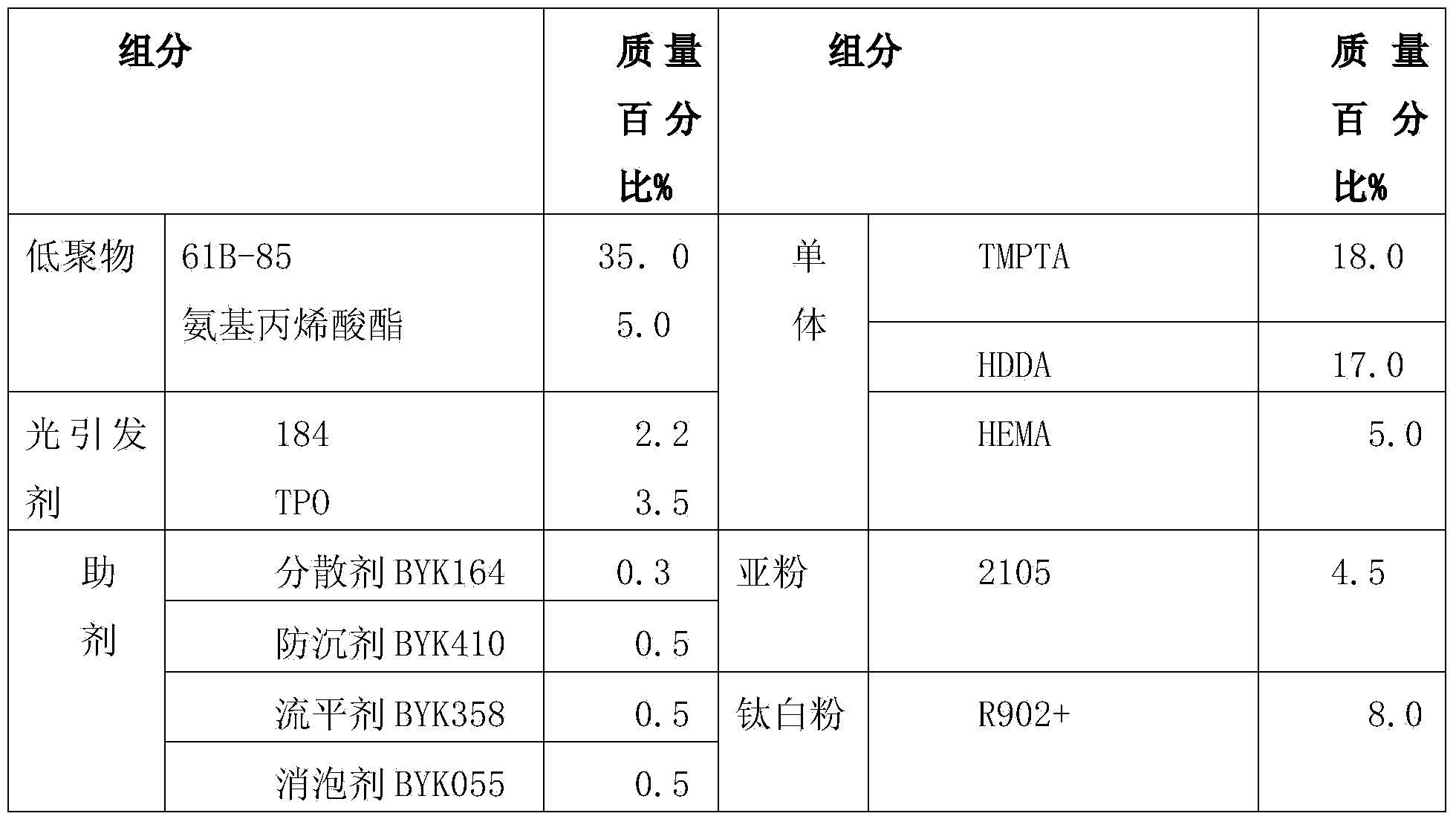

[0024] The formula of UV curable white curtain coating paint includes the following mass percentages (see Table 1):

[0025] Among them, the oligomers are mainly aliphatic urethane acrylate, which is Changxing's 61B-85, amino acrylate; the monomers are HEMA (hydroxyethyl methacrylate), acrylate TMPTA (trihydroxypropane triacrylate) and HDDA (1,6 hexanediol diacrylate); the photoinitiator is TPO (2,4,6-trimethylbenzoyl-diphenylphosphine oxide), 184 (1-hydroxycyclohexyl phenyl ketone) ; Sub-powder is Grace 2105; additives include dispersant BYK164, defoamer BYK055, anti-settling agent BYK410, and leveling agent BYK358; titanium dioxide is DuPont titanium dioxide R902+.

[0026] Table 1 Mass percentage of UV curable white curtain coating components

[0027]

[0028] Mix and dissolve the above components, oligomers and a part of acrylate monomers, then add additives and stir again, then add matte powder and titanium dioxide and stir at high speed until the dispersion fineness ...

Embodiment 2

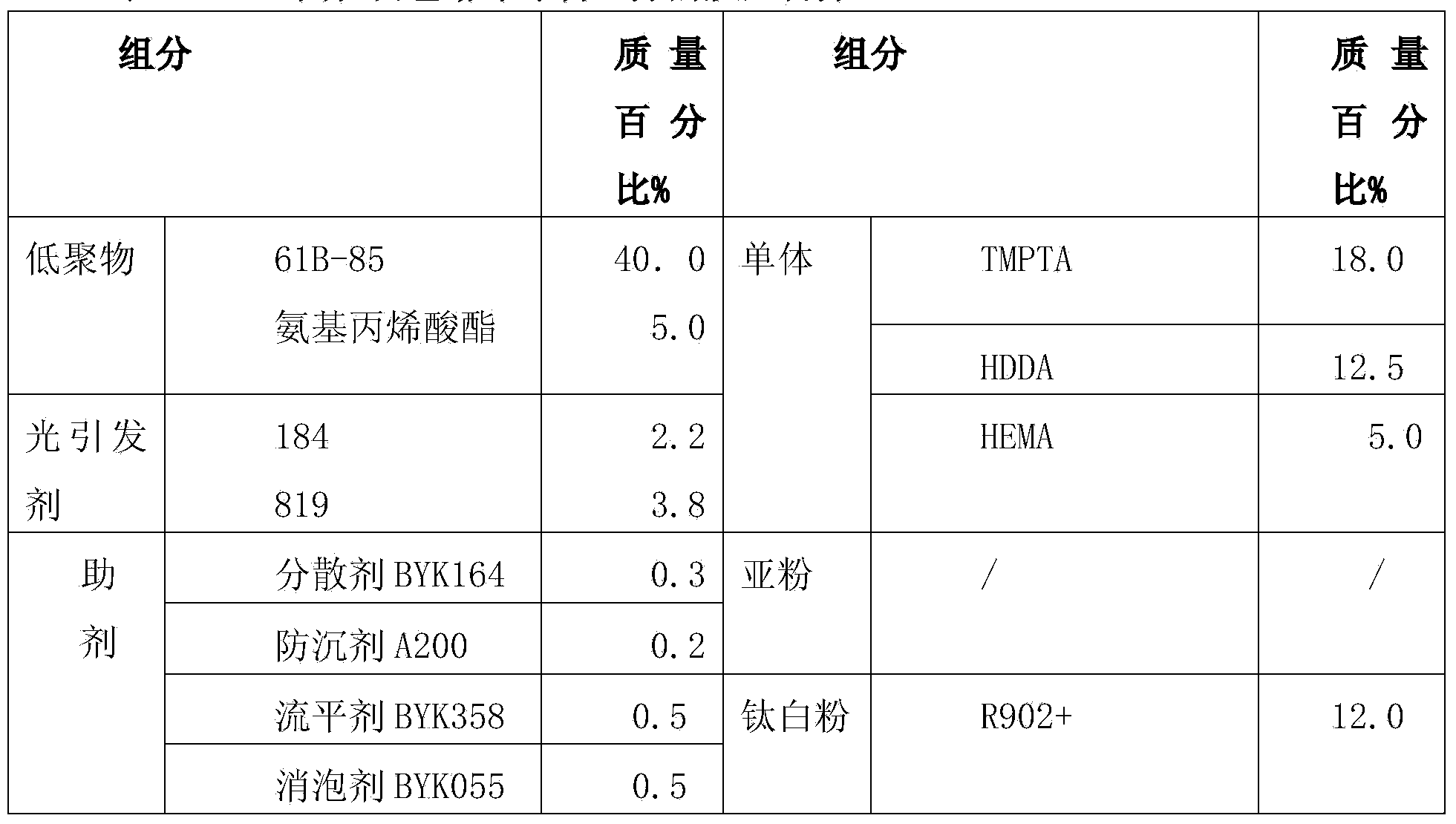

[0031] The formula of UV curable white curtain coating paint includes the following mass percentages (see Table 2):

[0032] Among them, the oligomers are mainly aliphatic urethane acrylate, which is Changxing's 61B-85, amino acrylate; the monomers are HEMA (hydroxyethyl methacrylate), acrylate TMPTA (trihydroxypropane triacrylate) and HDDA (1,6 hexanediol diacrylate); the photoinitiator is 819 (phenyl bis (2,4,6-trimethylbenzoyl) phosphine oxide), 184 (1-hydroxycyclohexyl phenyl ketone ); additives include dispersant BYK164, defoamer BYK055, anti-settling agent fumed silica A200, and leveling agent BYK358; titanium dioxide is DuPont titanium dioxide R902+.

[0033] Table 2 Mass percent of UV curable white curtain coating components

[0034]

[0035] Mix and dissolve the above components, oligomers and a part of acrylate monomers, then add additives and stir again, then add matte powder and titanium dioxide and stir at high speed until the dispersion fineness is reached, t...

Embodiment 3

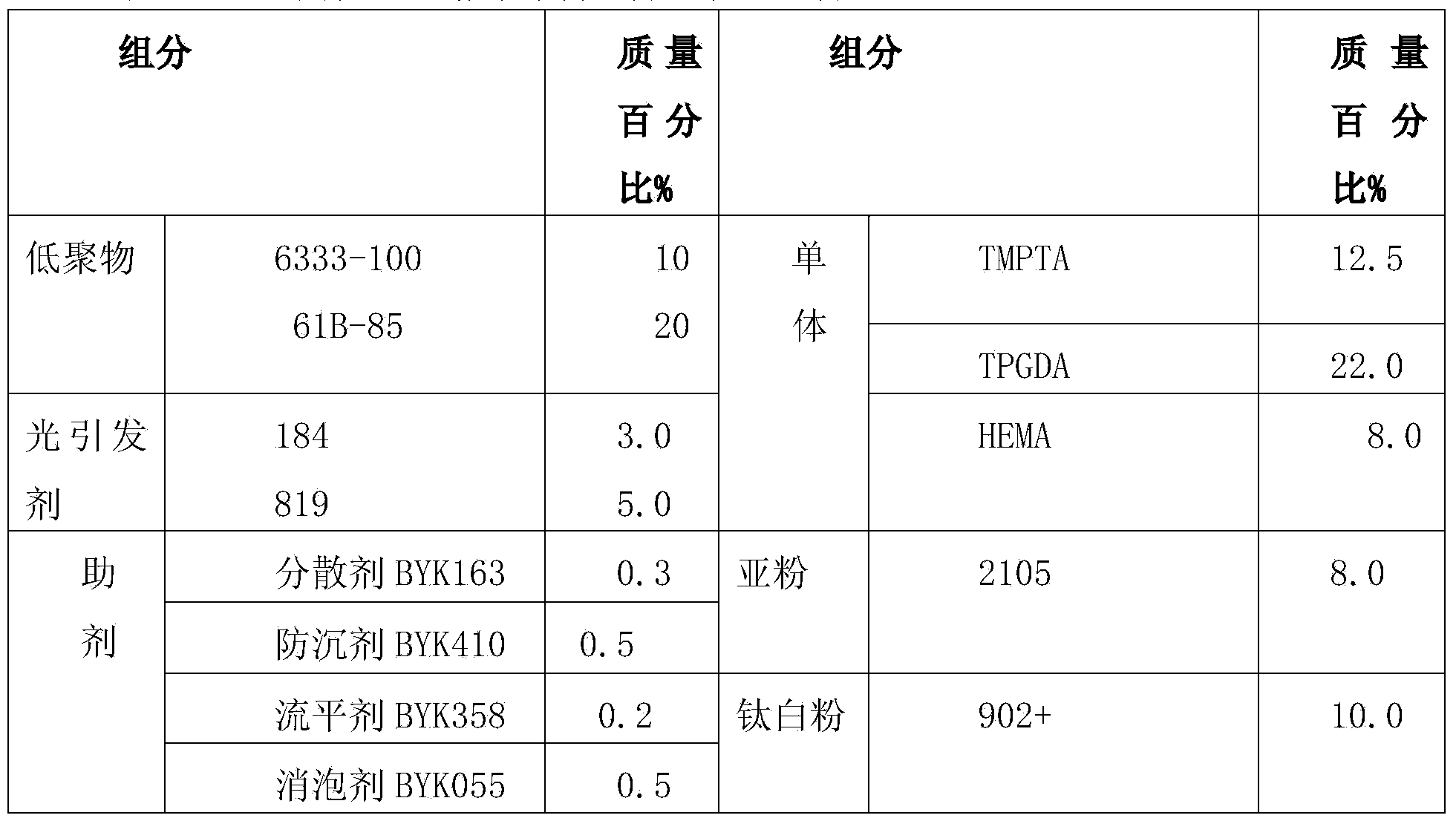

[0038] The formula of UV curable white curtain coating paint includes the following mass percentages (see Table 3):

[0039] Among them, the oligomers are mainly aliphatic polyurethane acrylate is 61B-85 of Changxing Company, polyester acrylate is 6333-100 of Changxing Company; monomers are TMPTA (trihydroxypropane triacrylate) and TPGDA (trihydroxypropane triacrylate) of acrylate Propylene glycol diacrylate) and HEMA (hydroxyethyl methacrylate); the photoinitiator is 819 (phenyl bis (2,4,6-trimethylbenzoyl) phosphine oxide), 184 (1 -Hydroxycyclohexyl phenyl ketone); sub-powder is Grace's 2105; additives include dispersant BYK163, defoamer BYK055 and anti-sedimentation agent BYK410; titanium dioxide is DuPont titanium dioxide R902+.

[0040] Table 3 Mass percent of UV curable white curtain coating components

[0041]

[0042] Mix and dissolve the above components, oligomers and a part of acrylate monomers, then add additives and stir again, then add matte powder and titanium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com