Solid State Lighting Device

A lighting device and solid-state technology, which is applied to lighting devices, lighting device parts, lighting and heating equipment, etc., to achieve the effects of miniaturization, easy miniaturization, and improvement of light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

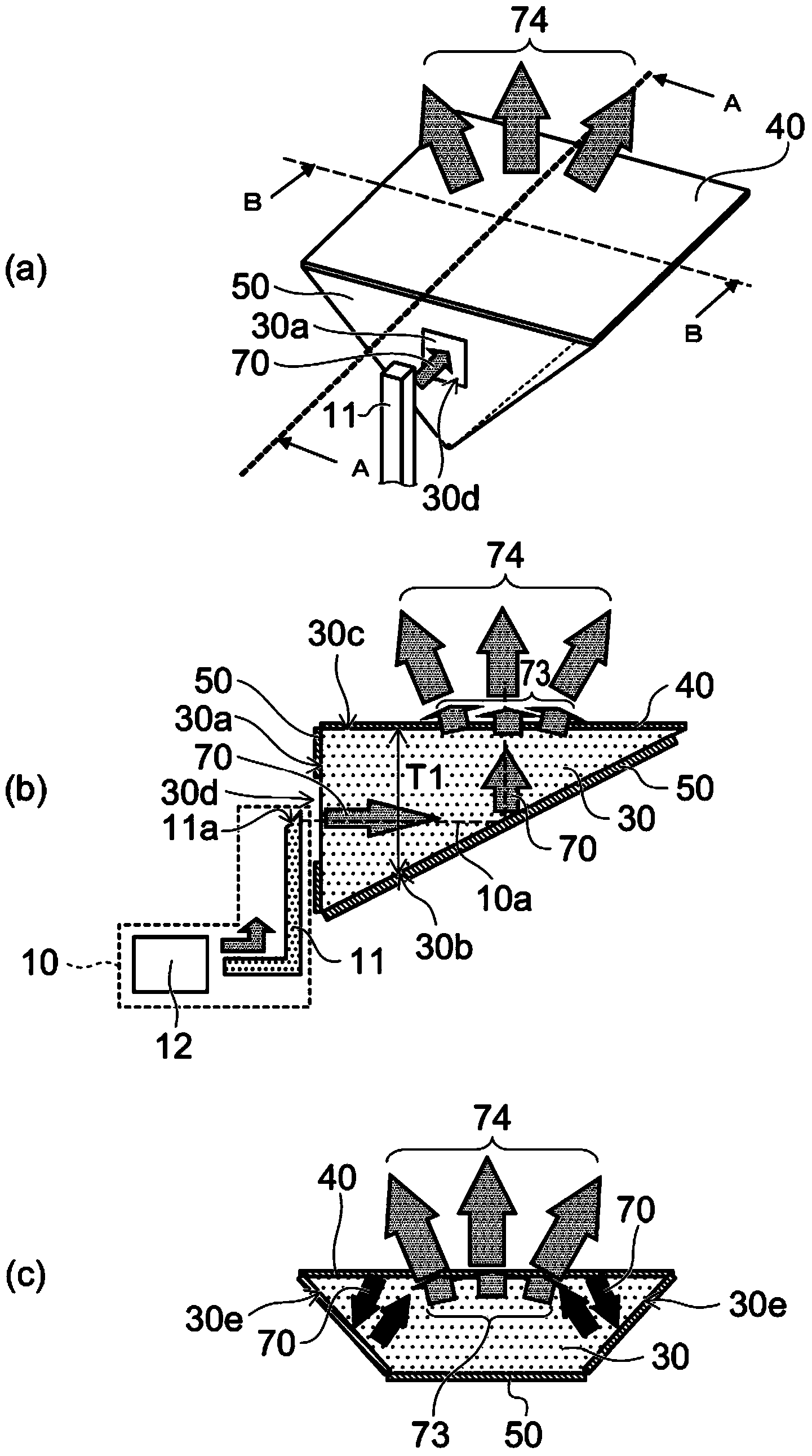

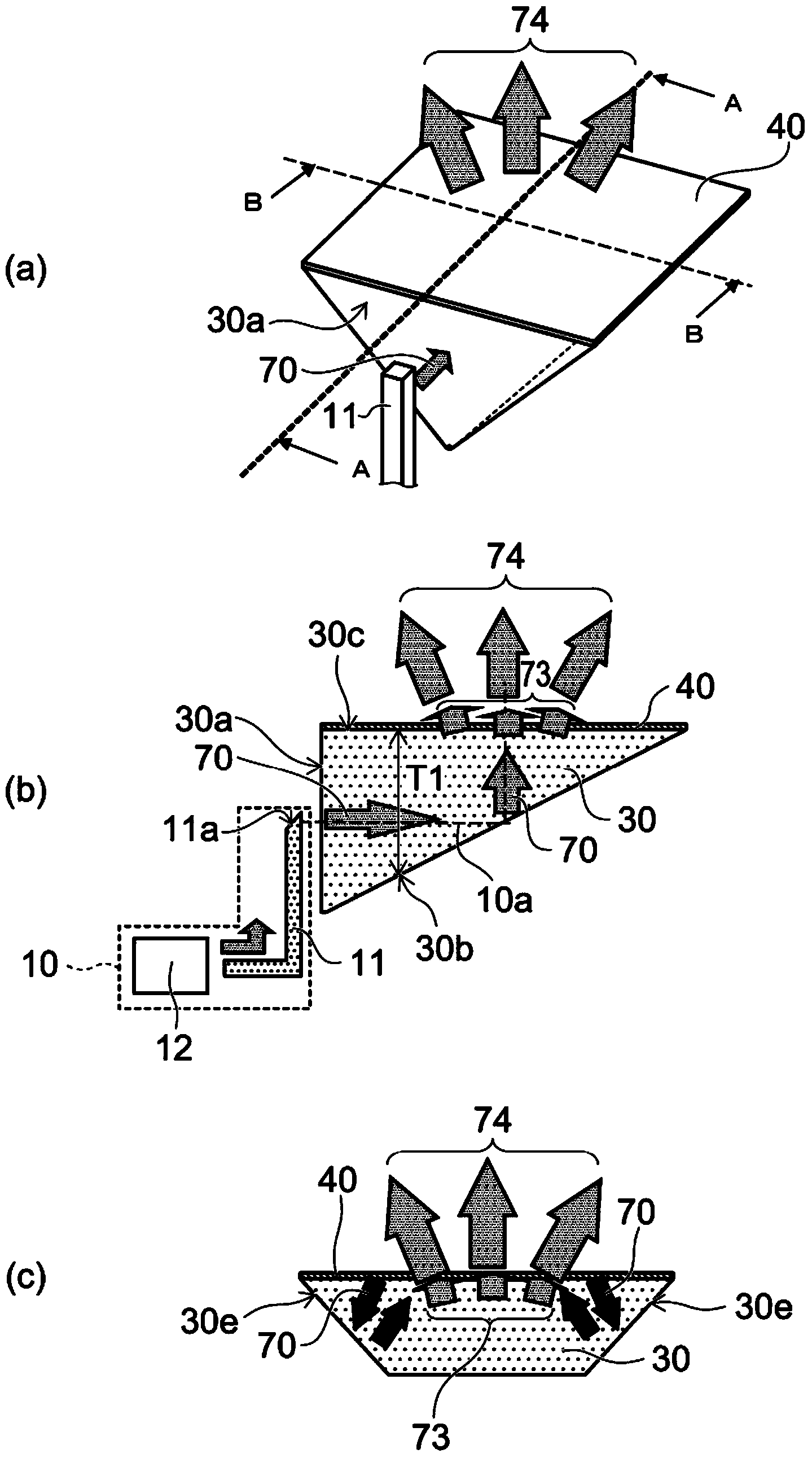

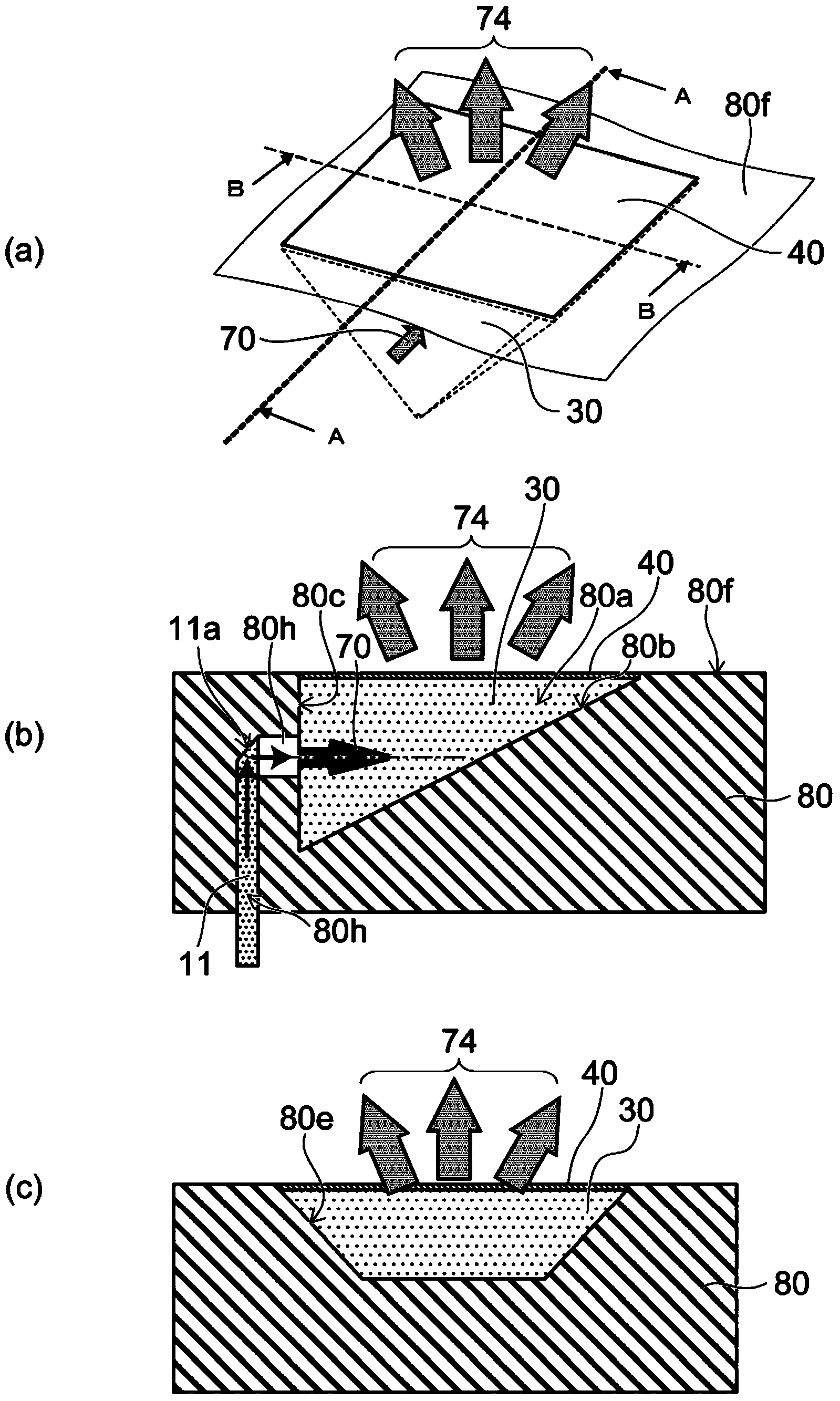

[0016] figure 1 (a) is a schematic perspective view of the solid-state lighting device according to the first embodiment, figure 1 (b) is a schematic cross-sectional view along line A-A, figure 1 (c) is a schematic cross-sectional view along line B-B.

[0017] The solid-state lighting device includes an irradiation unit 10 , a light guide body 30 , a wavelength conversion layer 40 , and a reflection unit 50 .

[0018] The irradiation unit 10 may include a semiconductor laser 12 that emits laser light 70 and an incident light guide unit 11 . The wavelength of the laser light 70 can be set to wavelengths such as ultraviolet light (380 nm) to blue light (490 nm). The light guide portion 11 may be, for example, an optical fiber or the like.

[0019] The light guide body 30 has an incident surface 30 a into which the laser light 70 is introduced, an incline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com