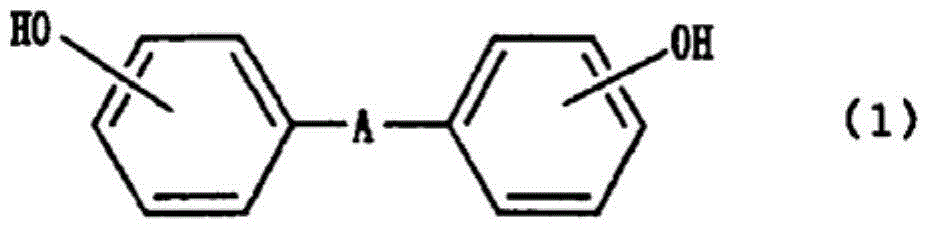

Method of consistently producing diallylbisphenols

A diallyl bisphenol, bisphenol technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., to achieve the effects of easy handling, reduction of manufacturing processes, and prevention of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] In an autoclave equipped with a stirrer, add 3,800 g of ethylene glycol monobutyl ether and 500 g of water to mix, and then add 1,000 g (4.0 moles) of 4,4'-dihydroxydiphenyl sulfone (hereinafter, bisphenol S ), 288 g (7.2 moles) of sodium hydroxide and 170 g (1.6 moles) of sodium carbonate. Next, 670 g (8.8 mol) of allyl chloride was added to form a closed state, and it was made to react by heating and stirring at 95 to 100° C. for 5 hours.

[0094] After the reaction was completed, the pressure was released, and the reaction liquid was further heated to distill off unreacted allyl chloride and the like. The distillate was liquid-separated into an upper layer and a lower layer. The upper layer (recovery solvent A) contained 165 g of ethylene glycol monobutyl ether.

[0095] After cooling the remaining reaction liquid in the still to 100° C., 1300 g of water was poured in, stirred to dissolve the inorganic salt by-product, separated, and the lower layer (water layer) w...

Embodiment 2

[0105] In the mixture of the total amount of recovered solvents A to C and 182 g of recovered solvent D in Example 1, add 145 g of ethylene glycol monobutyl ether, and add bisphenol S, sodium hydroxide and Sodium carbonate was reacted and post-treated in the same manner to obtain 1117 g of a refined product of bis(3-allyl-4-hydroxyphenyl)sulfone (yield to bisphenol S: 84.5%). The obtained purified bis(3-allyl-4-hydroxyphenyl)sulfone had an HPLC composition ratio (area percentage) of 97.1% and a melting point of 154 to 155°C.

Embodiment 3

[0107] In an autoclave equipped with a stirrer, 356 g of ethylene glycol monobutyl ether and 19 g of water were added and mixed, and 150 g (0.657 mol) of 2,2'-bis(4-hydroxyphenyl)propane (hereinafter, Bisphenol A), 53 g (1.325 mol) of sodium hydroxide and 14 g (0.132 mol) of sodium carbonate. Next, 121 g (1.581 mol) of allyl chloride was added to form an airtight state, and it was heated and stirred at 100 to 105° C. for 8 hours to make it react.

[0108] After completion of the reaction, allyl chloride was distilled off in the same manner as in Example 1, and a water solution was carried out. After neutralization, heat filtration was performed to obtain an ethylene glycol monobutyl ether solution of bisphenol A diallyl ether. The Na content of this reaction liquid was about 10 ppm. In addition, the HPLC composition ratio (area percentage) is 95.0% of 2,2-bis(4-allyloxyphenyl)propane, 0.2% of bisphenol A, 4-hydroxyphenyl-4'-allyloxybenzene Propane (hereinafter, bisphenol A m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com