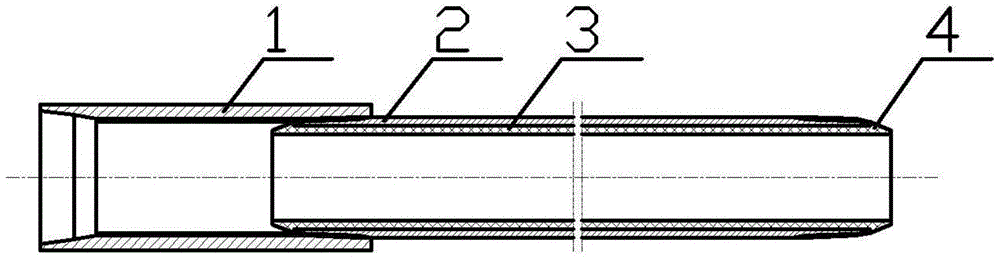

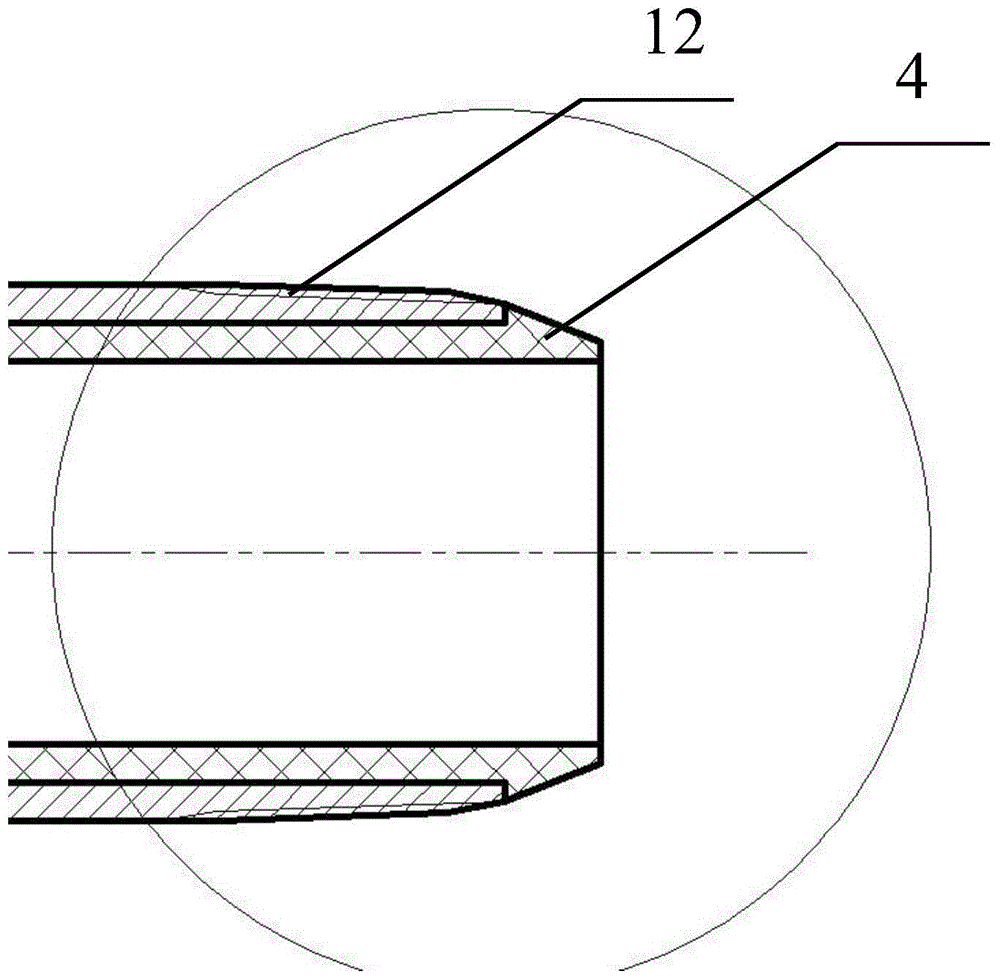

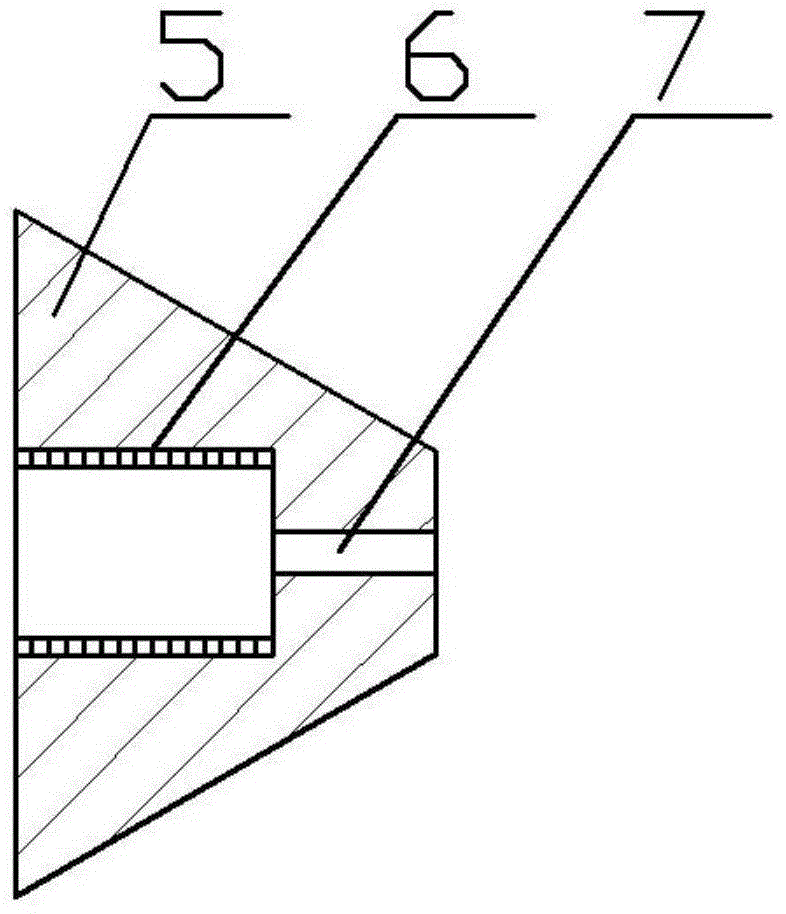

Preparation method of grafted cross-linked polyamide lined pipe and high temperature resistant lined oil extraction pipe

A technology for oil extraction pipes and high temperature resistance, which is applied in drilling pipes, casing pipes, earthwork drilling and production, etc., to achieve the effects of improving heat resistance, good acid resistance, and reducing the possibility of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A high-temperature-resistant lined oil suction pipe liner pipe, the liner pipe is prepared from the following kg components as special pellets, and the pellets are extruded to form a pipe:

[0058] Polyhexamethylene adipamide with a number average molecular weight of 30,000-50,000: 25kg;

[0059] EPDM rubber: 1kg;

[0060] Grafted polyolefin elastomer with a molecular weight of 50,000-100,000: 5kg;

[0061] N,N'-4,4'-diphenylmethane bismaleimide: 10kg;

[0062] Antioxidant 1010: 4kg;

[0063] Antiaging agent RD: 3kg;

[0064] Cross-linking agent DCP: 0.1kg;

[0065] Grafting catalyst rubidium trioxide: 0.05kg.

[0066] A preparation method for preparing the high-temperature-resistant lined oil suction pipe lining pipe, comprising the following steps: polyhexamethylene adipamide, EPDM rubber, grafted polyolefin elastomer, N,N' -4,4'-Diphenylmethane bismaleimide, antioxidant, anti-aging agent, crosslinking agent, grafting catalyst were mixed evenly with a high-speed...

Embodiment 2

[0074] A high-temperature-resistant lined oil suction pipe lining pipe material, the liner pipe material is prepared from the following kg components to form special pellets, and the pellets are extruded to form pipes:

[0075] Polyhexamethylene adipamide with a number average molecular weight of 30,000-50,000: 20kg;

[0076] EPDM rubber: 5kg;

[0077] Grafted polyolefin elastomer with a number average molecular weight of 50,000-100,000: 10kg;

[0078] N,N'-4,4'-diphenylmethane bismaleimide: 15kg;

[0079] Antioxidant 300: 1kg;

[0080] Antiaging agent D: 5kg;

[0081] Cross-linking agent PBO: 0.8kg;

[0082] Grafting catalyst rubidium trioxide: 0.015kg;

[0083] A preparation method for preparing the high-temperature-resistant oil-suction liner lining pipe, the steps of which are the same as in Example 1, wherein the parameters of the twin-screw extruder: Zone 1: 185°C, Zone 2: 290°C, Zone 3: 280°C, zone 4: 240°C, zone 5: 290°C, zone 6: 280°C, head temperature: 170°C, h...

Embodiment 3

[0089] A high-temperature-resistant lined oil suction pipe lining pipe material, the liner pipe material is prepared from the following kg components to form special pellets, and the pellets are extruded to form pipes:

[0090] Polyhexamethylene adipamide with a number average molecular weight of 30,000-50,000: 23kg;

[0091] EPDM rubber: 10kg;

[0092] Grafted polyolefin elastomer with a number average molecular weight of 50,000-100,000: 1kg;

[0093] N,N'-4,4'-diphenylmethane bismaleimide: 5kg;

[0094] Antioxidant BHT: 5kg;

[0095] Antiaging agent 4010: 1kg;

[0096] Cross-linking agent dicumyl peroxide: 0.4kg;

[0097] Grafting catalyst rubidium trioxide: 0.04kg.

[0098] A preparation method for preparing the high-temperature-resistant lined oil suction pipe lining pipe, the steps are the same as in Example 1, wherein the parameters of the twin-screw extruder: Zone 1: 180°C, Zone 2: 260°C, Zone 3: 300 ℃, zone 4: 280℃, zone 5: 240℃, zone 6: 230℃, head temperature: 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com