High-biological-stability semisynthetic metal cutting fluid and preparation method thereof

A biological stability, metal cutting fluid technology, applied in the direction of lubricating composition, etc., can solve the problems affecting the normal use function of cutting fluid, on-site environmental pollution, working fluid stratification, etc., to achieve excellent cleaning performance, excellent rust resistance, The effect of long service life

Inactive Publication Date: 2014-10-08

马思特(上海)化学有限公司

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Semi-synthetic metal cutting fluids contain a certain amount of mineral oil. During use, due to water, worker contact and contamination from on-site debris, corruption often occurs, resulting in the growth of a large number of bacteria or fungi in the cutting fluid, resulting in stratification of the working fluid. , odor, etc., which not only affect the normal use of cutting fluid, but also pollute the site environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

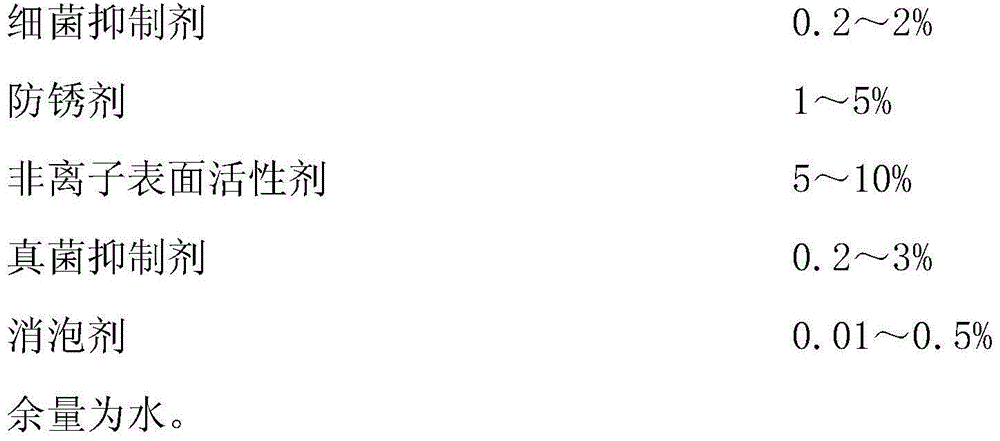

[0021] A semi-synthetic metal cutting fluid with high biological stability, its composition and content are as follows:

[0022]

[0023]

Embodiment 2

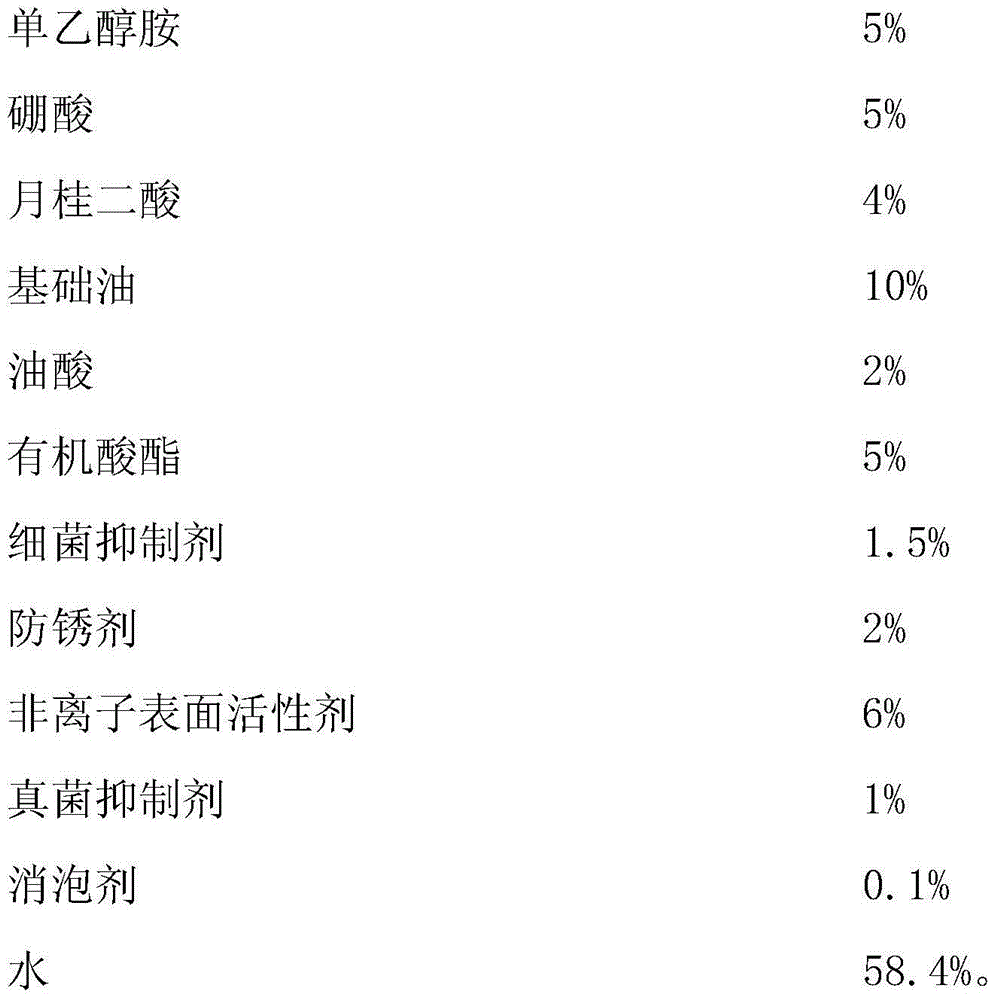

[0025] A semi-synthetic metal cutting fluid with high biological stability, its composition and content are as follows:

[0026]

Embodiment 3

[0028] A semi-synthetic metal cutting fluid with high biological stability, its composition and content are as follows:

[0029]

[0030]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a cutting fluid for metal working and a preparation method thereof, particularly a high-biological-stability semisynthetic metal cutting fluid. The cutting fluid is prepared from the following raw materials in percentage by weight: 1-10% of monoethanolamine, 2-10% of boric acid, 4-10% of dodecanedioic acid, 1-10% of base oil, 4-10% of oleic acid, 2-10% of organic acid ester, 0.2-2% of bacterial inhibitor, 1-5% of rust inhibitor, 5-10% of nonionic surfactant, 0.2-3% of fungus inhibitor, 0.01-0.5% of defoamer and the balance of water. The preparation method comprises the following steps: proportioning the material components according to the percentage by weight, adding the pure water, monoethanolamine, dodecanedioic acid and boric acid into a reaction kettle, continuously stirring for 30 minutes, adding the base oil, oleic acid, organic acid ester, bacterial inhibitor, rust inhibitor, nonionic surfactant and fungus inhibitor, continuously stirring for 30 minutes, finally adding the defoamer, and stirring until the fluid is uniform and transparent. Compared with the prior art, the cutting fluid provided by the invention has the advantages of favorable biological stability, excellent anti-rust property and excellent lubricating property.

Description

[technical field] [0001] The invention relates to a cutting fluid for metal processing and a preparation method thereof, in particular to a highly biologically stable semi-synthetic metal cutting fluid and a preparation method thereof. [Background technique] [0002] Semi-synthetic metal cutting fluids contain a certain amount of mineral oil. During use, due to water, worker contact and contamination from on-site debris, corruption often occurs, resulting in the growth of a large number of bacteria or fungi in the cutting fluid, resulting in stratification of the working fluid. , odor, etc., which not only affect the normal use of cutting fluid, but also pollute the site environment. [Content of the invention] [0003] The purpose of the present invention is to solve the above-mentioned deficiencies and provide a semi-synthetic metal cutting fluid with high biological stability and its preparation method, which has good biological stability, making it difficult to decay du...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M173/00

Inventor 沈恺悦王波朱红朱少保

Owner 马思特(上海)化学有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com