Method for brewing onion grape wine

A wine and onion technology, applied in the field of winemaking, can solve the problems of no large-scale sales, heavy onion odor, and difficulty in promotion, and achieve the effects of improving nutritional value and health care efficacy, reducing onion odor, and being easy to promote.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

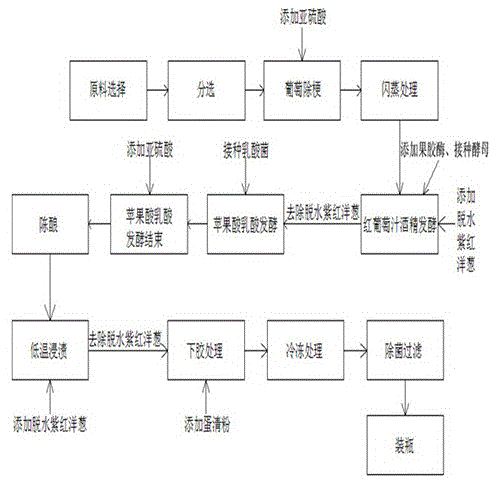

Image

Examples

Embodiment 1

[0048] In the third step of the above method, 0.4L / ton of sulfurous acid (sulfur dioxide content is 6%) is added in a balanced manner online to the destemmed grapes; in the fourth step, the grapes coming out of the buffer tank enter a sleeve heater, The grapes are quickly heated to 80°C, and the heated grapes enter the negative pressure tank; in the fifth step, 200g / m of high-quality Saccharomyces cerevisiae is inoculated 3 ; In the seventh step, after confirming the completion of malolactic fermentation, add sulfurous acid (sulfur dioxide content is 6%) 0.7L / m 3 ;In the tenth step, add 50g / m of egg white powder to the onion wine 3 .

Embodiment 2

[0050] In the third step of the above method, 0.2L / ton of sulfurous acid (sulfur dioxide content is 6%) is added in a balanced manner online to the destemmed grapes; in the fourth step, the grapes coming out of the buffer tank enter a sleeve heater, The grapes are quickly heated to 85°C, and the heated grapes enter the negative pressure tank; in the fifth step, 150g / m of high-quality Saccharomyces cerevisiae is inoculated 3 ; In the seventh step, after confirming the completion of malolactic fermentation, add sulfurous acid (sulfur dioxide content is 6%) 0.65L / m 3 ;In the tenth step, add egg white powder 60g / m to the onion wine 3 .

Embodiment 3

[0052] In the third step of the above method, 0.3L / ton of sulfurous acid (sulfur dioxide content is 6%) is added on-line to the destemmed grapes; in the fourth step, the grapes coming out of the buffer tank enter a sleeve heater, The grapes are quickly heated to 80°C, and the heated grapes enter the negative pressure tank; in the fifth step, 180g / m of high-quality Saccharomyces cerevisiae is inoculated 3 ; In the seventh step, after confirming the completion of malolactic fermentation, add sulfurous acid (sulfur dioxide content is 6%) 0.75L / m 3 ;In the tenth step, add egg white powder 30g / m to the onion wine 3 .

[0053] All of the above three embodiments can brew onion wine with little onion odor, good taste and high content of onion active ingredients.

[0054] The present invention adopts flash steaming treatment of raw materials, mixed alcoholic fermentation (alcoholic fermentation of red grape juice, malolactic fermentation) supplemented by low-temperature extraction pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com