Rare earth extraction and separation method

A separation method and extraction technology, applied in the field of extraction and separation of rare earths, can solve problems such as limited extraction capacity of rare earth elements, and achieve the effects of significant synergistic extraction effect, high extraction efficiency, and obvious synergistic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

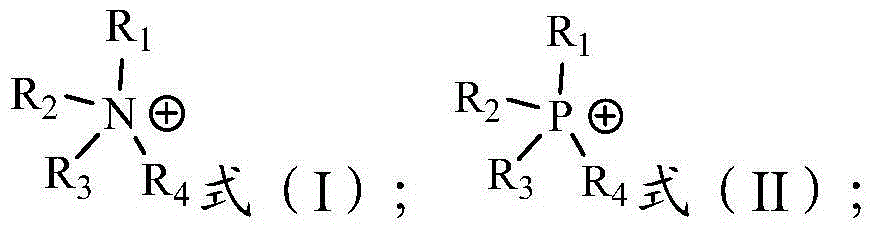

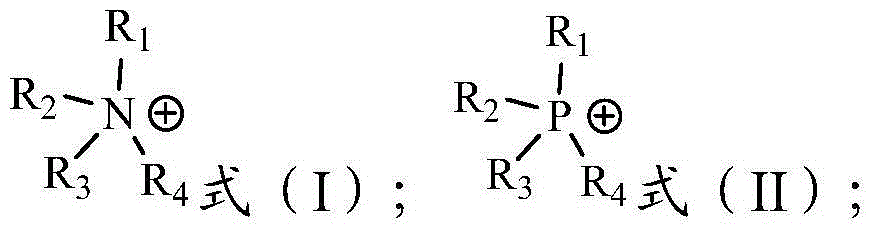

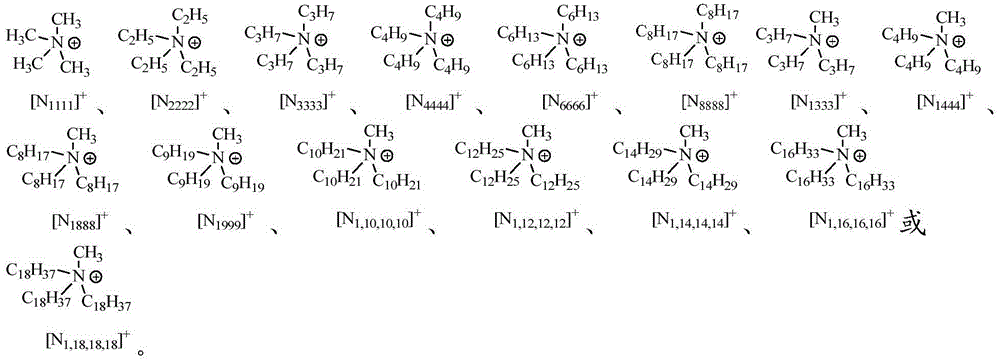

Method used

Image

Examples

Embodiment 1~5

[0042] Bifunctionalized ionic liquid tetraethylammonium di(2-ethylhexylphosphoric acid) [N 2222 ][P204] and tetraethylammonium 2-ethylhexylphosphonic acid 2-ethylhexyl ester [N 2222 ][P507] is the extractant, which is mixed with sulfonated kerosene and isooctyl alcohol to form an organic phase. The volume ratio of the mixed extractant, isooctyl alcohol and sulfonated kerosene in the organic phase is 0.10:0.10:0.80.

[0043] The concentration of rare earth ions is respectively prepared to be 0.01 mol / liter, the rare earth solution of pH=4.0, and the rare earth ions are respectively La 3+ 、Nd 3+ 、Eu 3+ 、Dy 3+ and Er 3+ .

[0044] The organic phase with a volume ratio of 1:1 is mixed with the rare earth solution, and extracted at room temperature, and the extraction stage is 1 stage.

[0045] After extraction, calculate its distribution ratio and co-extraction coefficient, the results show that tetraethylammonium bis (2-ethylhexyl phosphoric acid) [N 2222 ][P204] and tetra...

Embodiment 6~10

[0052] Tetra-n-butylammonium bis(2-ethylhexylphosphoric acid) [N 4444 ][P204] and tetra-n-butylammonium 2-ethylhexylphosphonic acid 2-ethylhexyl ester [N 4444 ][P507] is the extractant, which is mixed with sulfonated kerosene to form an organic phase. The volume ratio of the mixed extractant to sulfonated kerosene in the organic phase is 0.20:0.80.

[0053] The concentration of rare earth ions is 0.1 mol / liter, the rare earth solution of pH=3.0 is prepared respectively, and the rare earth ions are respectively La 3+ 、Nd 3+ 、Eu 3+ 、Dy 3+ and Er 3+ .

[0054] The organic phase with a volume ratio of 1:1 is mixed with the rare earth solution, and extracted at room temperature, and the extraction stage is 1 stage.

[0055] After the extraction, calculate its distribution ratio and co-extraction coefficient, the results show that tetra-n-butylammonium bis (2-ethylhexyl phosphoric acid) [N 4444 ][P204] and tetra-n-butylammonium 2-ethylhexylphosphonic acid 2-ethylhexyl ester [...

Embodiment 11~15

[0057] Bifunctional ionic liquid tetraethylammonium di(2-ethylhexylphosphoric acid) [N 2222 ][P204] and tetrabutylammonium 2-ethylhexylphosphonic acid 2-ethylhexyl ester [N 4444 ][P507] is the extractant, which is mixed with sulfonated kerosene and isooctyl alcohol to form an organic phase. The volume ratio of the mixed extractant, isooctyl alcohol and sulfonated kerosene in the organic phase is 0.10:0.10:0.80.

[0058] The concentration of rare earth ions is respectively prepared to be 0.01 mol / liter, the rare earth solution of pH=4.0, and the rare earth ions are respectively La 3+ 、Nd 3+ 、Eu3+ 、Dy 3+ and Er 3+ .

[0059] The organic phase with a volume ratio of 1:1 is mixed with the rare earth solution, and extracted at room temperature, and the extraction stage is 1 stage.

[0060] After extraction, calculate its distribution ratio and co-extraction coefficient, the results show that tetraethylammonium bis (2-ethylhexyl phosphoric acid) [N 2222 ][P204] and tetrabutyla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com