Sprinkling open type absorption heat pump system capable of recycling waste heat of airflow containing moisture

An absorption heat pump and spray technology, which is applied in adsorption machines, climate change adaptation, climate sustainability, etc., can solve the problem of limited latent heat recovery, low heat transfer coefficient of membrane heat transfer, and large heat transfer area, etc. problems, to achieve the effects of easy installation, operation and maintenance, reduced temperature and moisture content, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

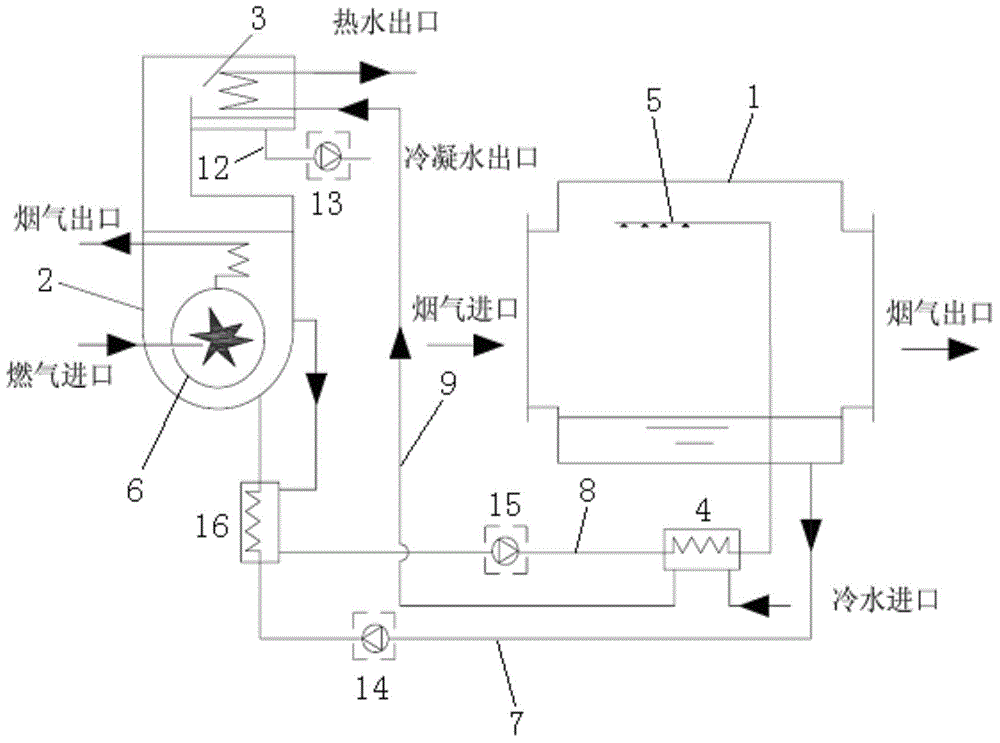

[0025] Such as figure 1 As shown, the heat pump system provided in this embodiment includes an absorber 1 , a generator 2 , a condenser 3 , a solution-water heat exchanger 4 , a spray device 5 and a driving heat source 6 . In this embodiment, the driving heat source 6 is driven by gas.

[0026] Wherein, a flue gas inlet and a flue gas outlet are provided on the side of the absorber 1 respectively, and the spray device 5 is arranged inside the absorber 1 above the flue gas inlet. The dilute solution outlet at the bottom of the absorber 1 is connected to the dilute solution inlet of the generator 2 through the dilute solution pipeline 7, and the concentrated solution outlet of the generator 2 is connected with the solution channel of the solution-water heat exchanger 4 and the Sprinkler 5 is connected. One side of the generator 2 is connected to the driving heat source 6 , the top of the generator 2 has a steam outlet, and the condenser 3 is connected to the steam outlet of th...

Embodiment 2

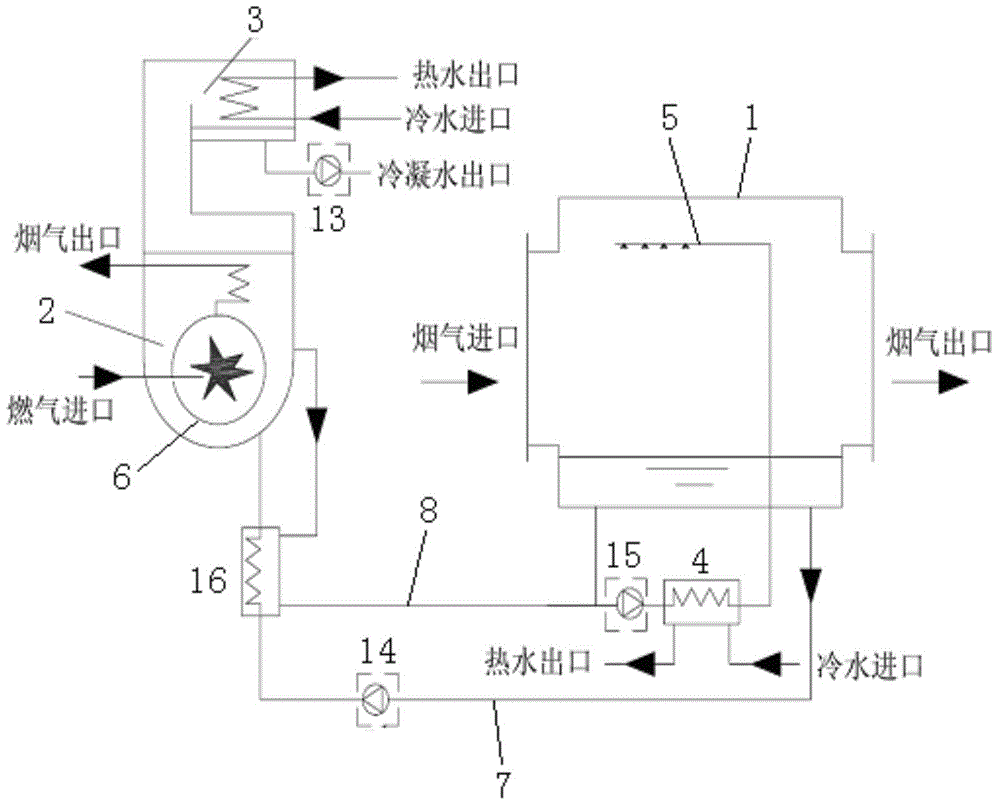

[0029] Such as figure 2 As shown, the difference between the heat pump system provided by this embodiment and the first embodiment is that the hot and cold water pipeline 9 is divided into two parallel paths, respectively connected to the water channel of the solution-water heat exchanger 4 and the heat exchange of the condenser 3 The cold water enters the water channel of the solution-water heat exchanger 4 and the heat exchange tube of the condenser 3 respectively, and then returns to the heat user respectively. Other connections and processes are the same as in Embodiment 1.

Embodiment 3

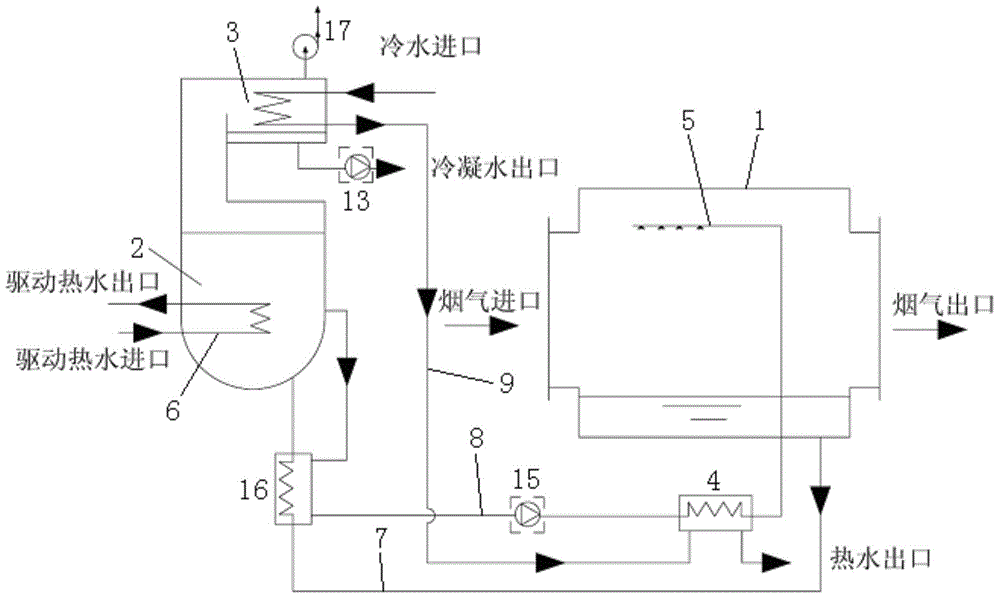

[0031] Such as image 3 As shown, the difference between the heat pump system provided in this embodiment and the first embodiment is that the driving heat source 6 is driven by hot water, and the cold water enters from the side of the condenser 3 and then flows out from the side of the solution-water heat exchanger 4 and return to the hot user. Other connections and processes are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com