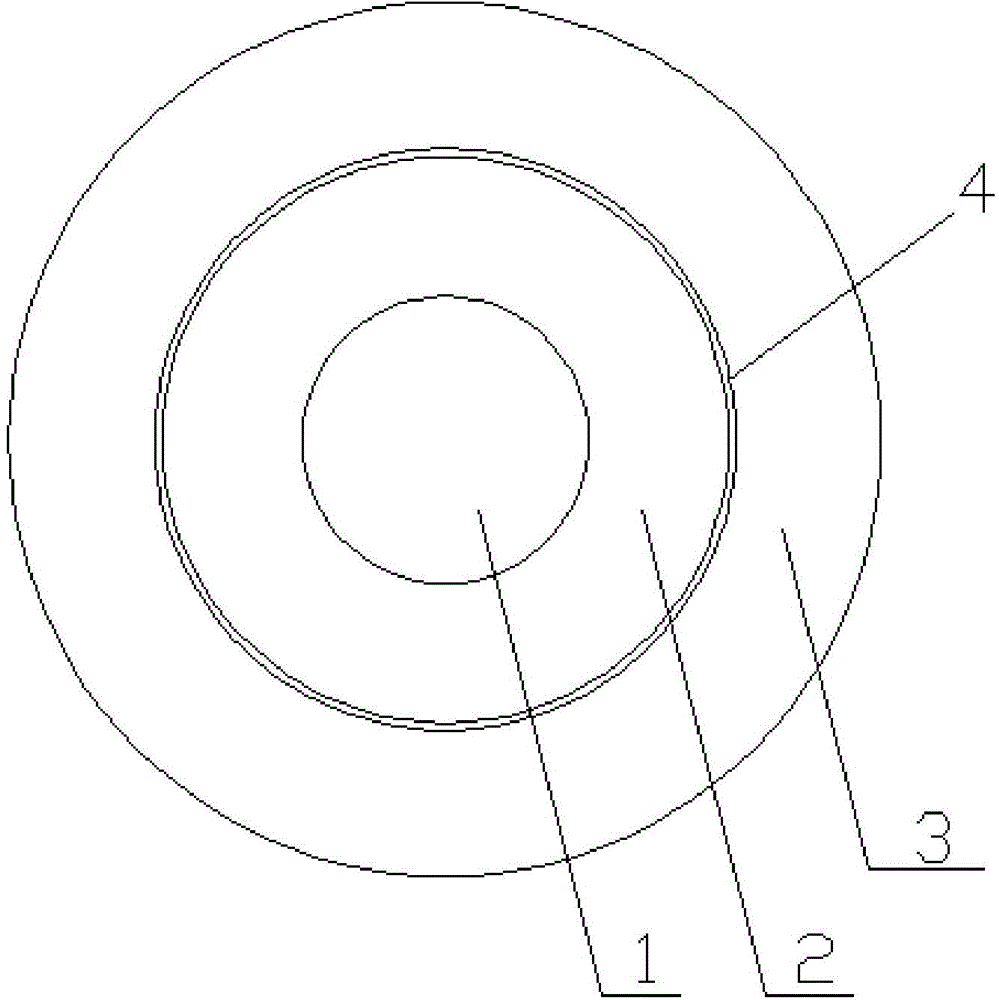

Cable

A cable and powder technology, which is applied in the field of electric power engineering to achieve good market prospects and excellent fire and waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The components and parts by weight of the cover layer material are: polyolefin elastomer POE845060 parts, magnesium hydroxide powder 20 parts, aluminum hydroxide powder 30 parts, magnesium oxide powder 1 part, fumed silica 1 part, ethyl 0.2 parts of alkene silane coupling agent, 5 parts of trioctyl trimellitate plasticizer, 1 part of dicumyl peroxide crosslinking agent;

[0027] The components and parts by weight of the water-repellent and flame-retardant coating material are: 40 parts of polyether, 5 parts of epoxy resin, 5 parts of polytetrafluoroethylene, 3 parts of magnesium hydroxide powder, 2 parts of aluminum hydroxide powder, 1 part of phthalate, 10 parts of polyurethane, 1 part of simethicone, 5 parts of fumed silica, 30 parts of ethanol.

Embodiment 2

[0029] The components and parts by weight of the cover layer material are: polyolefin elastomer POE845070 parts, magnesium hydroxide powder 30 parts, aluminum hydroxide powder 40 parts, magnesium oxide powder 2 parts, fumed silica 2 parts, ethyl 1 part of vinyl silane coupling agent, 7 parts of trioctyl trimellitate plasticizer, 3 parts of dicumyl peroxide crosslinking agent;

[0030] The components and parts by weight of the water-repellent and flame-retardant coating material are: 60 parts of polyether, 8 parts of epoxy resin, 15 parts of polytetrafluoroethylene, 5 parts of magnesium hydroxide powder, 3 parts of aluminum hydroxide powder, 2 parts of phthalates, 15 parts of polyurethane, 5 parts of simethicone, 10 parts of fumed silica, 50 parts of ethanol.

Embodiment 3

[0032] The components and parts by weight of the cover layer material are: polyolefin elastomer POE845065 parts, magnesium hydroxide powder 25 parts, aluminum hydroxide powder 35 parts, magnesium oxide powder 1.5 parts, fumed silica 1.5 parts, ethyl 0.5 parts of alkene silane coupling agent, 6 parts of trioctyl trimellitate plasticizer, 2 parts of dicumyl peroxide crosslinking agent;

[0033] The components and parts by weight of the water-repellent and flame-retardant coating material are: 50 parts of polyether, 7 parts of epoxy resin, 10 parts of polytetrafluoroethylene, 4 parts of magnesium hydroxide powder, 2.5 parts of aluminum hydroxide powder, 1.5 parts of phthalates, 12 parts of polyurethane, 3 parts of simethicone, 8 parts of fumed silica, 40 parts of ethanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com