Rare earth power cable

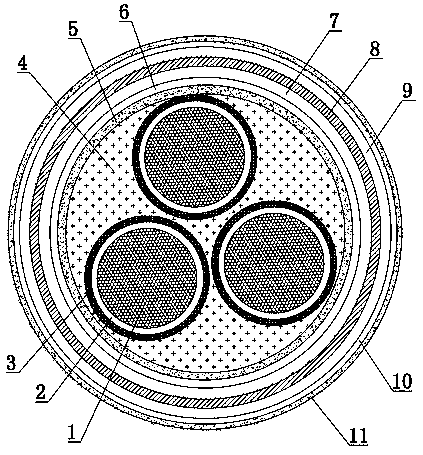

A power cable and rare earth technology, applied in the direction of power cables, power cables with shielding layer/conductive layer, insulated cables, etc., can solve problems such as shortening the service life of cables, breakdown of cable insulation layers, power operation accidents, etc., and achieve enhanced Mechanical strength, good shielding effect, high radial force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Fe: 0.30 wt%, Cu: 0.20 wt%, B: 0.01 wt%, Mg: 0.03 wt%, Si: 0.05 wt%, Zr: 0.10 wt%, Ni: 0.03 wt%, Ag: 0.01 wt%, Cr: 0.01 wt%, Mn: 0.01 wt%, Ti: 0.02 wt%, V: 0.02 wt%, Zn: 0.01 wt%, RE: 0.30 wt%, the remainder is Al and unavoidable impurities.

Embodiment 2

[0032] Fe: 0.60 wt%, Cu: 0.30 wt%, B: 0.02 wt%, Mg0.05 wt%, Si: 0.10 wt%, Zr: 0.15 wt%, Ni: 0.06 wt%, Ag: 0.02 wt%, Cr: 0.03 wt%, Mn: 0.03 wt%, Ti: 0.04 wt%, V: 0.05 wt%, Zn: 0.04 wt%, RE: 0.60 wt%, the remainder is Al and unavoidable impurities.

Embodiment 3

[0034] Fe: 0.450 wt%, Cu: 0.25 wt%, B: 0.015 wt%, Mg: 0.04 wt%, Si: 0.08 wt%, Zr: 0.12 wt%, Ni: 0.05 wt%, Ag: 0.015 wt%5, Cr : 0.02 wt%2, Mn: 0.02 wt%2, Ti: 0.03wt%, V: 0.04wt%, Zn: 0.025 wt%, RE: 0.50 wt%, and the rest are Al and unavoidable impurities.

[0035] The rare earth material components of the rare earth refractory layer 10 and the rare earth water blocking layer 11 formed by coating on the outer sheath 9 include the following examples:

[0036] Embodiment one:

[0037] Rare earth refractory material components include: fluorine rubber 8 wt%, aluminum hydroxide 5 wt%, rare earth oxide 2 wt%, glycerol 1 wt%, silicon carbide 2 wt%, lanthanum phosphate 3 wt%, gadolinium zirconate 6 wt%, the remainder is epoxy resin; the material components of the rare earth water blocking layer include: 35 wt% epoxy resin, 8 wt% tung oil, 4 wt% rare earth oxide, 5 wt% magnesium oxide, 6 wt% zinc oxide, and the remaining For nitrile rubber.

[0038] Embodiment two:

[0039] Rare ear...

PUM

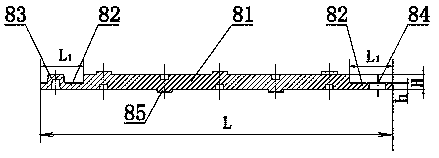

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com