Valve-controlled sealing lead-acid storage battery for starting and stopping of automobiles

A lead-acid battery, valve control technology, applied in the direction of lead-acid battery, lead-acid battery construction, battery, etc., can solve the problems of increased corrosion rate of the battery grid, easy water loss of the battery, battery swelling, etc., to reduce the occurrence of corrosion Probability, effect of reducing the number of grain boundaries and reducing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

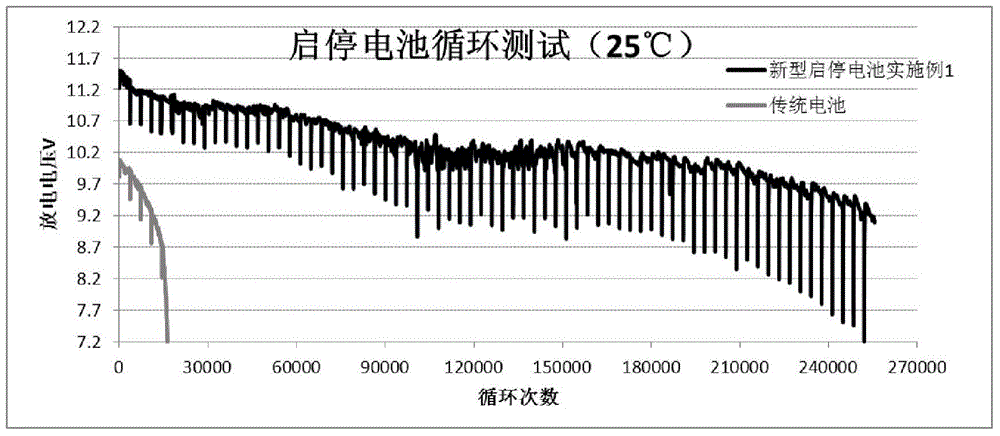

Embodiment 1

[0020] The composition of the positive grid alloy is: Ca: 0.065%, Sn: 1.20%, Yb: 0.03%, and the balance is Pb. The fabricated grid was heat-treated at 300°C for 15 min, and then cooled naturally to room temperature. Through metallographic microscope observation, it can be clearly seen that the alloy unit cell produced by this scheme ( Figure 5 ) compared to conventional alloys ( Figure 4 ) is significantly larger and the number of grain boundaries is reduced, thereby reducing the risk of failure due to grid corrosion when the battery is used at high temperatures.

[0021] Add 0.8% silicon dioxide to the dilute sulfuric acid electrolyte of the battery. Before mixing, it is required to stir the silica with a high-speed rotary machine. After using colloidal silica, the average pore size of the separator is reduced from 10 μm to 5 μm.

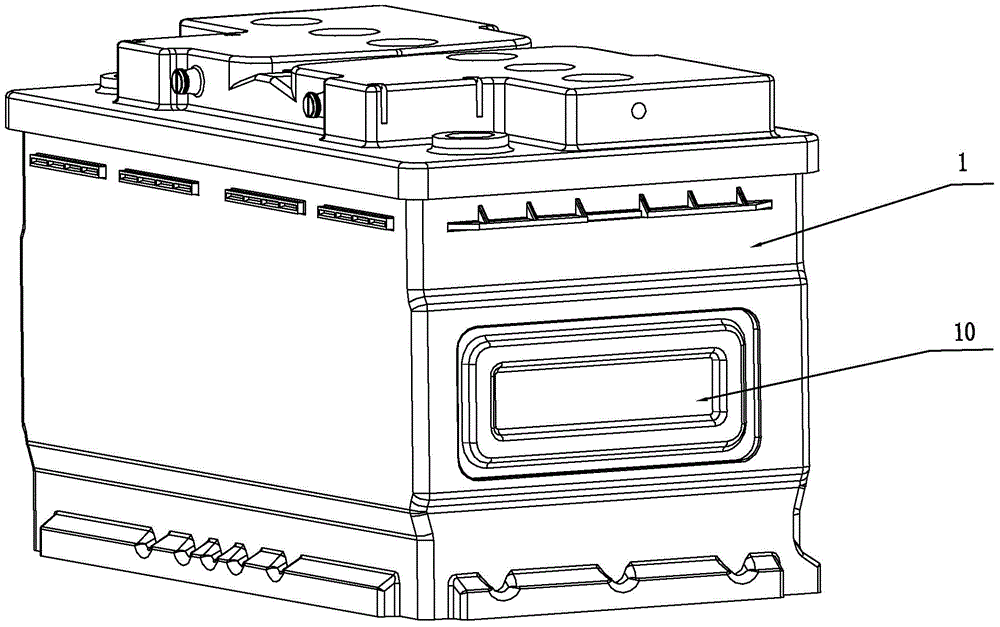

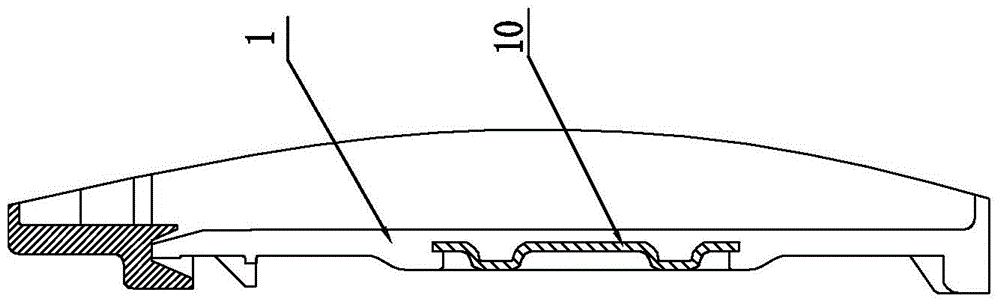

[0022] Refer to attached picture. A metal reinforcing rib 10 is symmetrically embedded (or adhered) on both sides of the 12V 80Ah plastic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com