High-sulfur crude oil gas recovery system for docks

A high-sulfur crude oil, recovery and treatment technology, applied in the direction of vapor condensation, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high fuel cost and low concentration, and achieve the effect of great energy saving and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

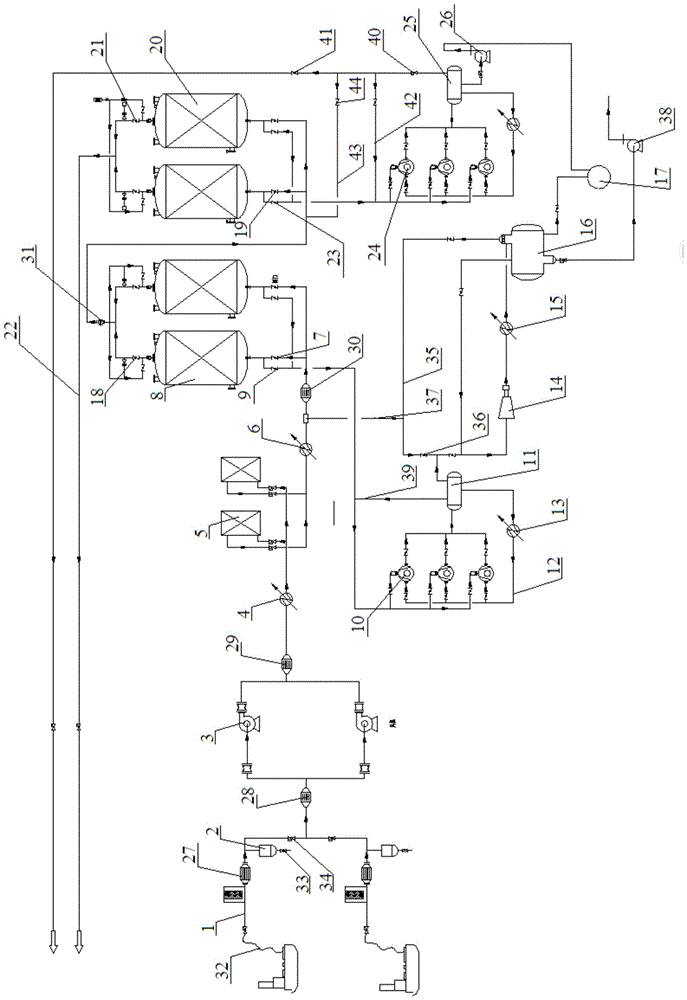

[0034] like figure 1 As shown, the purpose of the high-sulfur crude oil gas recovery and treatment system at the terminal is to recover the crude oil gas in production at the two loading and unloading berths. Oil and gas are collected by special oil and gas pipelines on shore, and recovered through two-stage dedicated carbon adsorption oil and gas recovery units. The heavy hydrocarbons recovered in the first stage are compressed and cooled to a liquid state. The light ends recovered in the second stage are concentrated and used as boiler fuel.

[0035] The hydrocarbons produced by the first set of stage vacuum pumps are sent to the compressor and then to the cooler to convert it into liquid form for storage, ready to be used as boiler fuel. The oil and gas desorbed by the second set of vacuum pumps can be directly used for boiler combustion. The switchover time from adsorption to regeneration cycle was 15 minutes.

[0036] The whole set of oil and gas recovery system inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com