Preparation method of photocatalyst functional road material

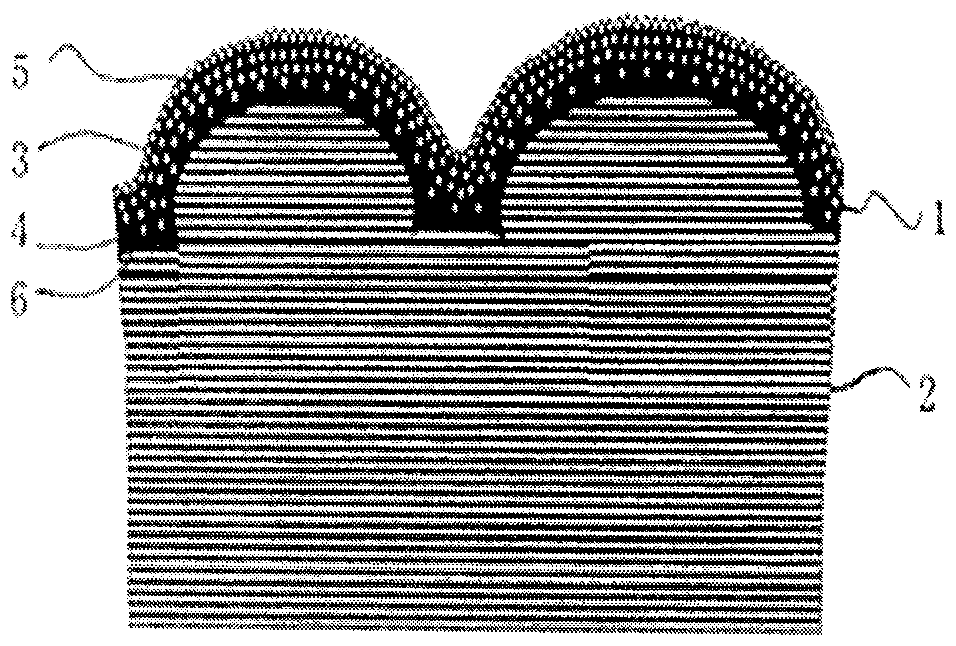

A technology of road materials and photocatalyst, which is applied in the field of preparation of photocatalyst functional road materials, can solve the problems of small specific surface area, lack of self-cleaning ability, and influence of water permeability of porous materials, so as to increase the specific surface area, expand the application field, and improve water permeability rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Use granite crushed stones with an average particle size of 3.5mm and asphalt as raw materials, mix and heat them to make asphalt concrete permeable material samples with a length of 100mm×width 50mm×thickness 5mm and a porosity of 30% according to the construction requirements of permeable concrete roads; , nano-recombined titanium dioxide 60, silica sand powder 200, weakly acidic water (PH value=4) 80, water reducing agent 2, the mass ratio of inorganic resin emulsion 2 to make photocatalyst suspension; Spray the permeable material sample block, spray 5g per asphalt concrete permeable material sample block, and immediately use 100% carbonic acid high-pressure gas to blow the sprayed surface after spraying, so that the surface can reach room temperature and quickly dry and harden.

Embodiment 2

[0014] Use granite crushed stones with an average particle size of 3.5mm and asphalt as raw materials, mix and heat them to make asphalt concrete permeable material samples with a length of 100mm×width 50mm×thickness 5mm and a porosity of 30% according to the construction requirements of permeable concrete roads; , nano-recombined titanium dioxide 60, silica sand powder 200, weakly acidic water (PH value=5) 80, water reducing agent 2, the mass ratio of inorganic resin emulsion 2 to make photocatalyst suspension; Spray the permeable material sample block, spray 5.5g per asphalt concrete permeable material sample block, and immediately use 100% carbonic acid high-pressure gas to blow the sprayed surface after spraying, so that the surface can reach normal temperature and quickly dry and harden.

Embodiment 3

[0016] Use granite crushed stones with an average particle size of 3.5mm and asphalt as raw materials, mix and heat them to make asphalt concrete permeable material samples with a length of 100mm×width 50mm×thickness 5mm and a porosity of 30% according to the construction requirements of permeable concrete roads; , nano-recombined titanium dioxide 60, silica sand powder 200, weakly acidic water (PH value=6) 80, water reducer 2, inorganic resin emulsion 2 mass ratio to make photocatalyst suspension; The permeable material sample block is sprayed, and each asphalt concrete permeable material sample block is sprayed 6 times. Immediately after spraying, 100% carbonic acid high-pressure gas is used to blow the sprayed surface to make the surface reach normal temperature and quickly dry and harden.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com