Patents

Literature

37results about How to "Increase the concentration of negative oxygen ions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmental-friendly coating and preparation technology thereof

InactiveCN104893470AImprove immunityIncrease the concentration of negative oxygen ionsCoatingsActivated carbonPollutant

The invention discloses an environmental-friendly coating and a preparation technology thereof. Activated bamboo charcoal and negative ion releasing agents are added in the environmental-friendly coating, so that the environmental-friendly coating can release negative oxygen ions for a long time; on one hand, the activated bamboo charcoal in the environmental-friendly coating adsorbs pollutants such as formaldehyde in the air, on the other hand, the negative oxygen ions released from the environmental-friendly coating enable PM2.5 particles in the air to aggregate and settle, and the pollutants such as formaldehyde in the air are bonded with the negative oxygen ions and are reduced into harmless substances; the negative oxygen ions are increased, so that the cardio-pulmonary function of people can be benefited, the metabolism can be promoted, and immunity of an organism can be improved; meanwhile, the air can be fresher as the negative oxygen ions in the air are increased, wherein the negative oxygen ion content in the fresh air is not lower than 1000-1500 ions per cubic centimeter according to the World Health Organization standards. The environmental-friendly coating begins to take effect after being smeared and applied on a wall surface, and no energy is consumed in the processes of smearing and applying the environmental-friendly coating on the wall surface, so that the secondary pollution caused by energy consumption for removal of pollutants in the air is avoided.

Owner:NINGBO JIANLIKANG BIOLOGICAL RES SCI ANDTECH CO LTD

Negative oxygen ion energy chinlon roll and preparing method thereof

InactiveCN110565372AQuick clearEnhance metabolic functionAnimal fibresHigh concentrationHazardous substance

The invention provides a negative oxygen ion energy chinlon roll and a preparing method thereof. The negative oxygen ion energy chinlon roll is prepared from, by weight, 30-50 parts of a taxus chinensis extract liquor, 1-5 parts of rare earth terbium, 1-5 parts of rare earth ytterbium, 30-50 parts of tourmaline, 10-30 parts of titanium dioxide, 15-85 parts of emulsion, 105-135 parts of micromolecule-group water and a proper amount of silk cloth, wherein the hardness of the micromolecule-group water is 180-280, and the pH value is 7.3-8.4. The negative oxygen ion energy chinlon roll can releasehigh-concentration negative oxygen ions, and the high-concentration negative oxygen ions can quickly remove formaldehyde, haze and other hazardous substances which are all positive charges in air andfree radicals in the human body through the electric neutralization effect; meanwhile, the metabolic function of cells of the human body is promoted, ageing is delayed, lymphatic circulation is enhanced, blood circulation of the human body is promoted, and thus the negative oxygen ion energy chinlon roll is beneficial to the body health.

Owner:成都康源量子生物技术研究院

Decorative material with negative oxygen ion releasing environmentally-friendly and health-care functions and preparation method of decorative board therefrom

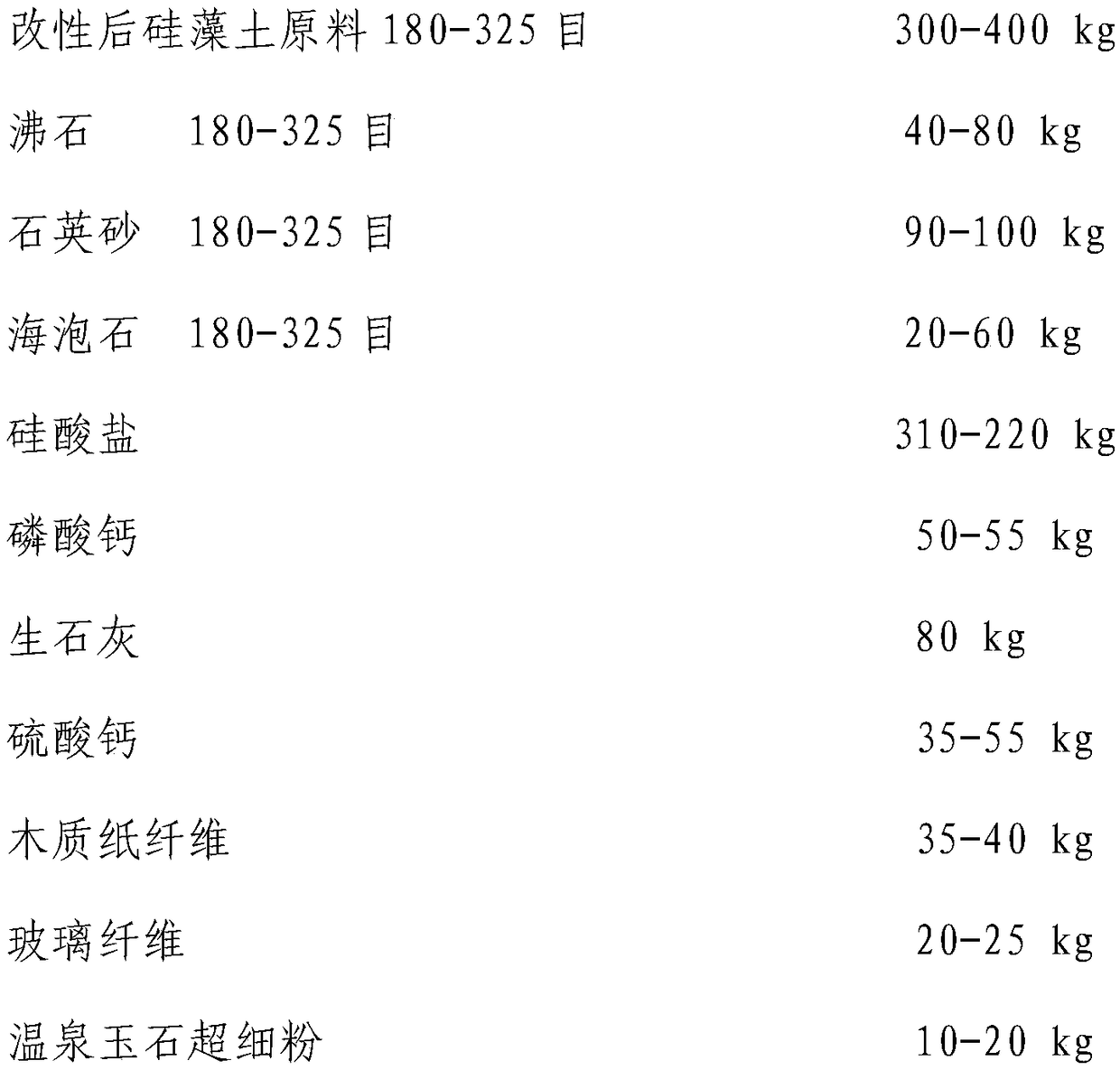

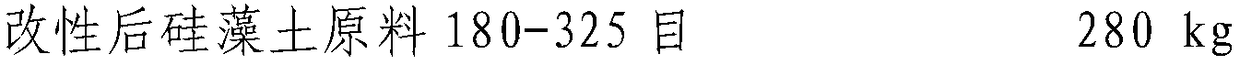

The invention belongs to the field of building interior wall decorating materials, and particularly relates to a light-weight, gas-permeable and humidity-regulating composite material for an interiorwall, which is compounded by virtue of unique microporous properties of a diatom material matrix, is healthy and environmentally-friendly, has excellent performance in regulating the humidity of an indoor space (good moisture absorption and moisture release), has high gas permeability, can release negative ions, and have a health-care function, and a preparation method thereof. A decorative material with the negative oxygen ion releasing environmentally-friendly and health-care functions and a decorative board therefrom can be directly cut by using a wallpaper knife, can be directly nailed, can be directly processed by using a woodworking tool plane, can directly replace a sandwich panel, a wood board, a plywood and a simulated wood board in subsequent processing, and can be directly usedfor furniture manufacturing, cabinet combination manufacturing and the like; many problems such as roll stickiness, cracking and low qualification rate of a finished product due to strong adsorption force between diatomite and bentonite in the moulding process of the board are solved.

Owner:北京未来空间美居科技有限公司

Photocatalyst functional road material preparation method

ActiveCN104098291AImprove adsorption capacitySolve the problem of decomposing organic substratesMicroparticleWater reducer

The invention discloses a photocatalyst functional road material preparation method. The method comprises the following steps: 1, using broken granite with the average particle size of 3.5mm and asphalt as raw materials, mixing, heating, and making asphalt concrete permeable material sample blocks with the length of 100mm, the width of 50mm, the thickness of 5mm and the void fraction of 30% according to permeable concrete road construction requirements; using alumina cement and silica sand powder as aggregates and nanometer recombinant titanium dioxide microparticles obtained after 1500DEG C high temperature sintering as a photocatalyst, adding a water reducer and an inorganic resin emulsion, mixing with a weakly acidic solution (with the pH value of 4-6), and carrying out high frequency oscillation to prepare a photocatalyst suspension; and 3, spraying the asphalt concrete permeable material sample blocks with the prepared photocatalyst suspension, and instantly blowing the sprayed surface by a 100% carbonic acid high pressure gas to realize the normal temperature rapid drying hardening of the surface.

Owner:BEIJING JIANYUAN TIANDI ENVIRONMENTAL PROTECTION TECH

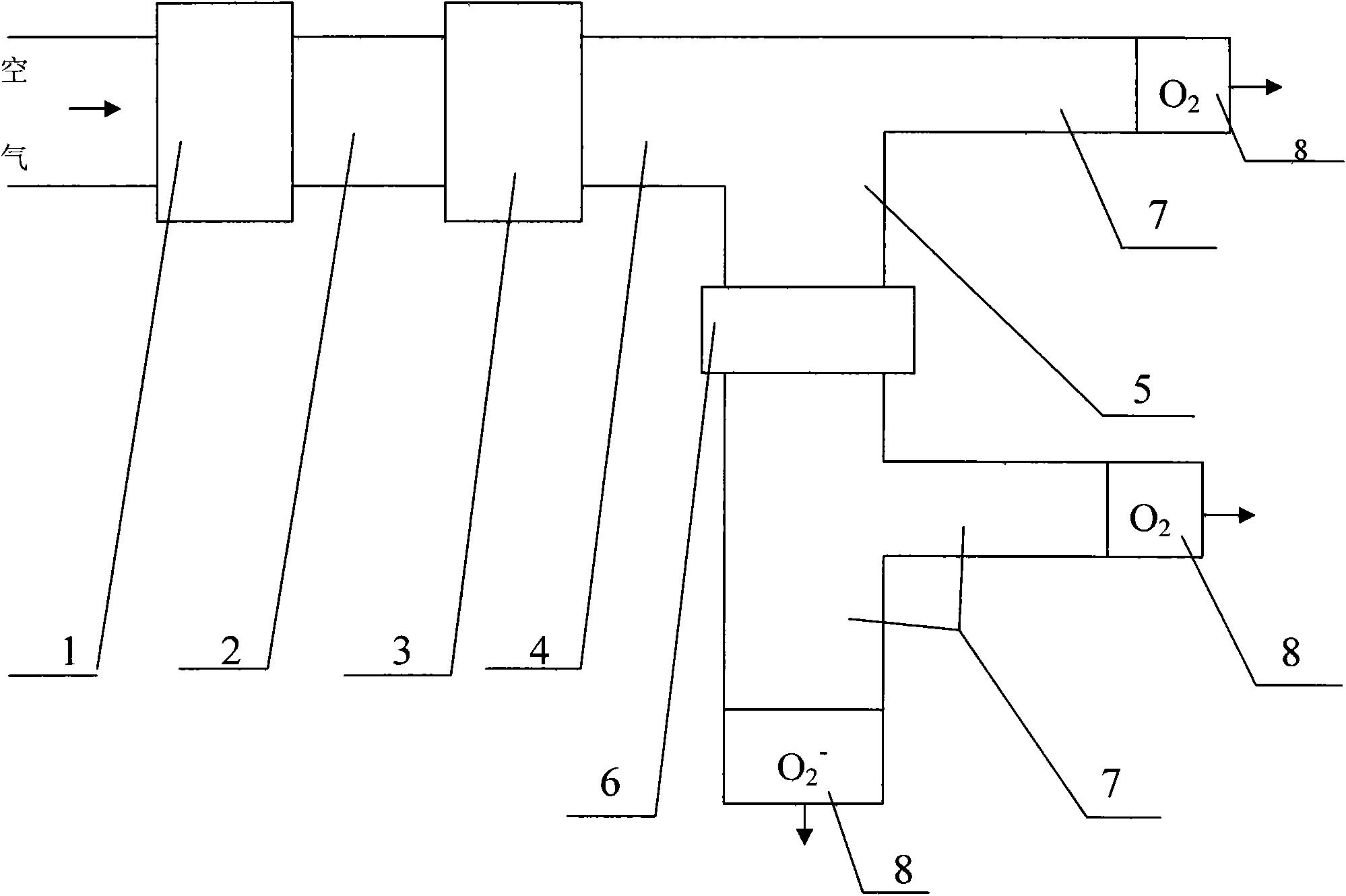

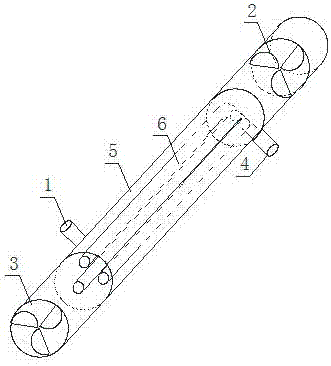

Quick air disinfection and purification system

InactiveCN101871679AImprove technical effectEfficient disinfection and purificationLighting and heating apparatusSpace heating and ventilation detailsHigh concentrationOxygen ions

The invention relates to a quick air disinfection and purification system, an ion catching type quick air purifier is arranged at a main air inlet of a central air conditioner host with a pipeline and an air inlet of a larger branch pipeline, and ozone-free high-performance negative oxygen ion generators are simultaneously arranged at all tail-end outlets of a central air conditioner for emitting high-concentration pure negative oxygen ions into the air. The quick air purifier consists of a negative oxygen ion emission array consisting of a negative high-voltage power supply and negative oxygen ion emitting units, and a built-in grounded electrical dust collector. The concentration of negative oxygen ions is very high, thereby having short length of the electrical dust collector, small air resistance, high dust removal efficiency, energy conservation and environmental protection. The pure negative oxygen ion generators are additionally arranged at all the outlets of the central air conditioner, thereby realizing the air eutrophication, simultaneously realizing the secondary purification of air pollutants, and further improving the cleanliness and the degree of eutrophication of the air.

Owner:蔡尔太

Multifunctional healthcare cloth and technology for processing same

InactiveCN104544590AIncrease concentrationActivate human cellsUndergarmentsProtective garmentBamboo charcoalFar infrared

The invention relates to multifunctional healthcare cloth and a technology for processing the same, and belongs to the technical field of textile fabrics. The multifunctional healthcare cloth comprises, by weight, 10-40 parts of soybean fibers, 10-60 parts of bamboo charcoal fibers, 10-30 parts of magnetic fibers, 10-60 parts of cotton fibers and 10-60 parts of far-infrared fibers. An implementation method includes uniformly mixing the soybean fibers, the bamboo charcoal fibers, the magnetic fibers, the cotton fibers and the far-infrared fibers with one another according to certain weight proportions to obtain mixtures, and then purifying the mixtures to obtain functional fiber spinning liquid; filtering and defoaming the functional fiber spinning liquid, then placing the functional fiber spinning liquid in spinning machines and forming liquid trickles by the aid of spinning nozzles; solidifying the liquid trickles to obtain as-spun fibers; manufacturing the multifunctional healthcare cloth from the as-spun fibers by the aid of weaving or knitting methods. The multifunctional healthcare cloth and the technology have the advantages of high moisture conducting speed and deodorization anion content, good breathability, excellent antibacterial and mildew-proof abilities, powerful antistatic function and capability of greatly relieving irritation to skins.

Owner:QINGDAO HUASHEN NANO TECH

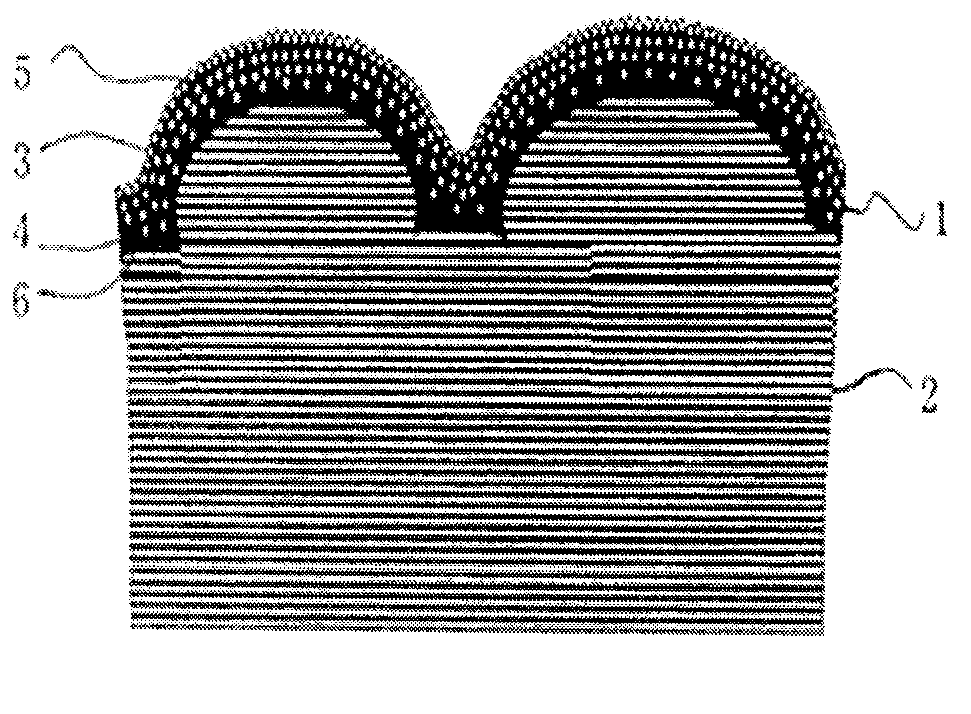

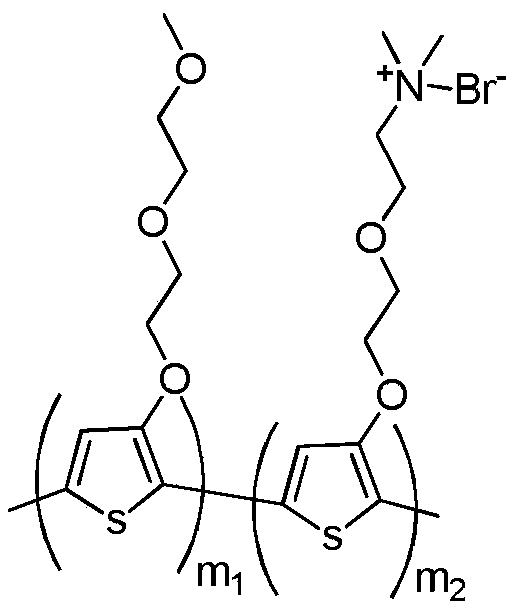

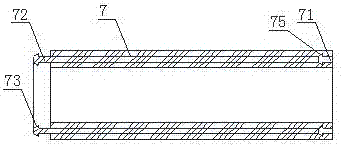

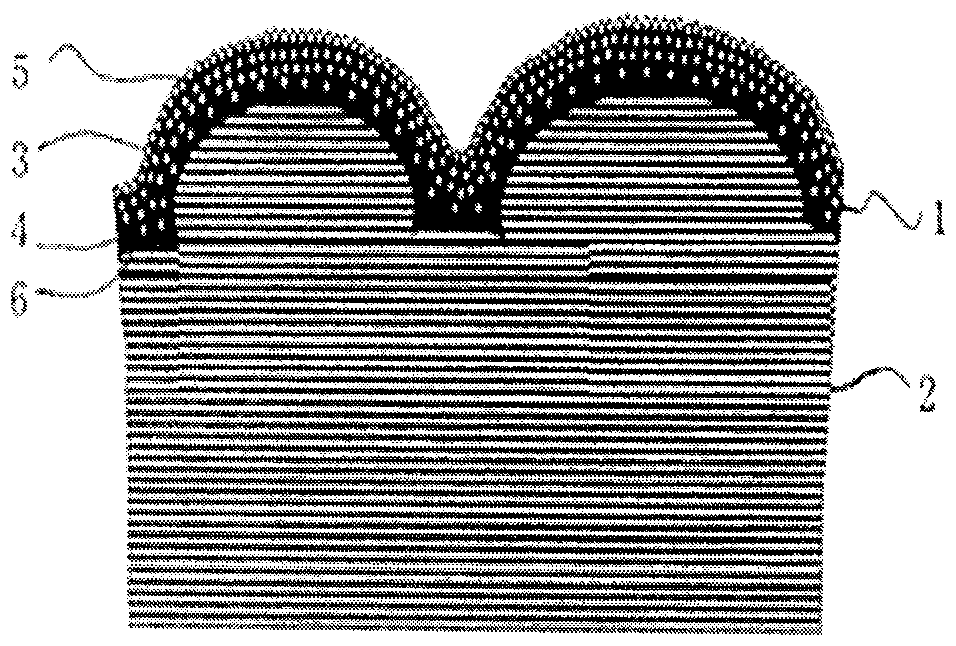

Composite high-molecular material film and preparation method thereof

PendingCN110511426AIncrease the concentration of negative oxygen ionsZero pollutionRubber derivative coatingsChemical industryBenzeneAluminium

The invention provides a composite high-molecular material film and a preparation method thereof, the composite high-molecular material film comprises a heat conduction micropore base material arranged on a bottom layer, the heat conduction micropore base material is coated with a high-molecular polymer coating, a functional auxiliary agent is arranged in the high-molecular polymer coating, and the functional auxiliary agent at least comprises a negative oxygen ion functional auxiliary agent; and the high-molecular polymer coating is of a coating structure capable of blocking a gas and being selectively permeable for water molecules. The composite high-molecular material film can be applied to a fresh air system, can conduct heat, blocks a gas and is permeable for water molecules, exchangeof sensible heat and latent heat can be achieved, the problems that a traditional exchange paper core cannot be washed with water, goes mouldy and the like are solved, and the problems that an exchange aluminum core cannot recover latent heat, is high in cost, and the like are also solved. The composite high-molecular material film at least contains a negative oxygen ion functional additive, cangenerate negative oxygen ions, decomposes and eliminates formaldehyde, benzene and the like in the air, neutralizes dust particles, destroys bacteria, pathogenic bacteria and mould molecules, comprehensively purifies the air, improves the indoor negative oxygen ion concentration, and protects the human body.

Owner:ZHONGSHAN FORTUNE WAY ENVIRONMENTAL TECH CO LTD

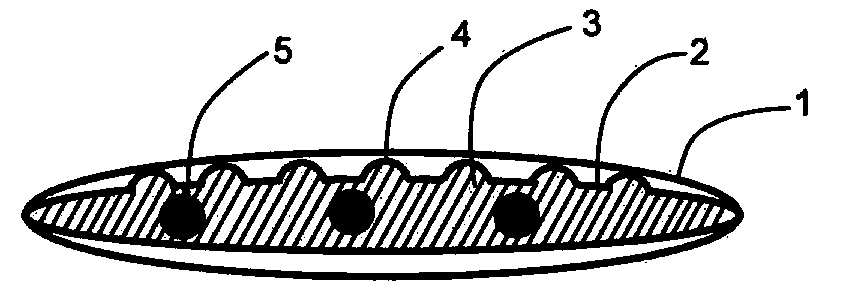

Negative oxygen ion filler and health-care negative oxygen ion bra pad

InactiveCN103948183AGood for healthIncrease the concentration of negative oxygen ionsMedical devicesBrassieresPhysical chemistryOxygen ions

The invention relates to a negative oxygen ion product, and particularly relates to a nano negative oxygen ion filler, and further relates to a health-care bra pad filled with the nano negative oxygen ion filler. The nano negative oxygen ion filler comprises silanized nano negative ion powder, mineral oil and the balance being a filling agent. The health-care bra pad filled with the nano negative oxygen ion filler comprises a fabric outer bag formed by overlapping and edge-sealing an upper-layer fabric and a lower-layer fabric, a plastic inner bag is arrange in the fabric outer bag, and is formed by overlapping an upper plastic layer and a lower plastic layer and connected with the fabric outer bag in an edge sealing manner, and the plastic inner bag is filled with the negative oxygen ion filler. The nano negative oxygen ion filler is capable of forming a negative ion air environment through generating negative ions; the concentration of the released negative oxygen ions is high, and the health of a woman can be improved and enhanced. The mineral oil used by the nano negative oxygen ion filler is capable of enabling the health-care bra pad as a finished product to have a relatively good soft effect and enabling people to feel relatively comfortable.

Owner:蒋福兵

Air purifying method

InactiveCN107152730AGood effectImprove efficiencyMechanical apparatusGas treatmentActivated carbonCarbon dioxide

The invention discloses an air purifier. The air purifier comprises primary-effect filtration, HEPA efficient filtration, activated carbon absorption, photocatalyst sterilization and negative oxygen ion adding performed in sequence, wherein a turbocharging circulating device for providing pressure for flowing of gas and a refrigeration, heating and dehumidification device for adjusting the temperature and the humidity of the gas are arranged between the primary-effect filtration and the HEPA efficient filtration; and air passes through a heat recovery device when leaving indoors. Outdoor fresh air is fed indoors after treatment by such modes as primary-effect and efficient dust removing filtration, photocatalyst sterilization and negative oxygen ion adding through an intake port connected outdoors to form positive pressure indoors; indoor dirty air is diluted by using an air dynamics principle; and under airflow movement, the indoor dirty air is exhausted outdoors through door gaps and window gaps, so that the concentration of indoor carbon dioxide is reduced, the purification is efficient, and the effects of isolating the dust, isolating the noise, removing the bacteria and removing peculiar smell are achieved.

Owner:SICHUAN JIANYUAN ENERGY SAVING TECH CO LTD

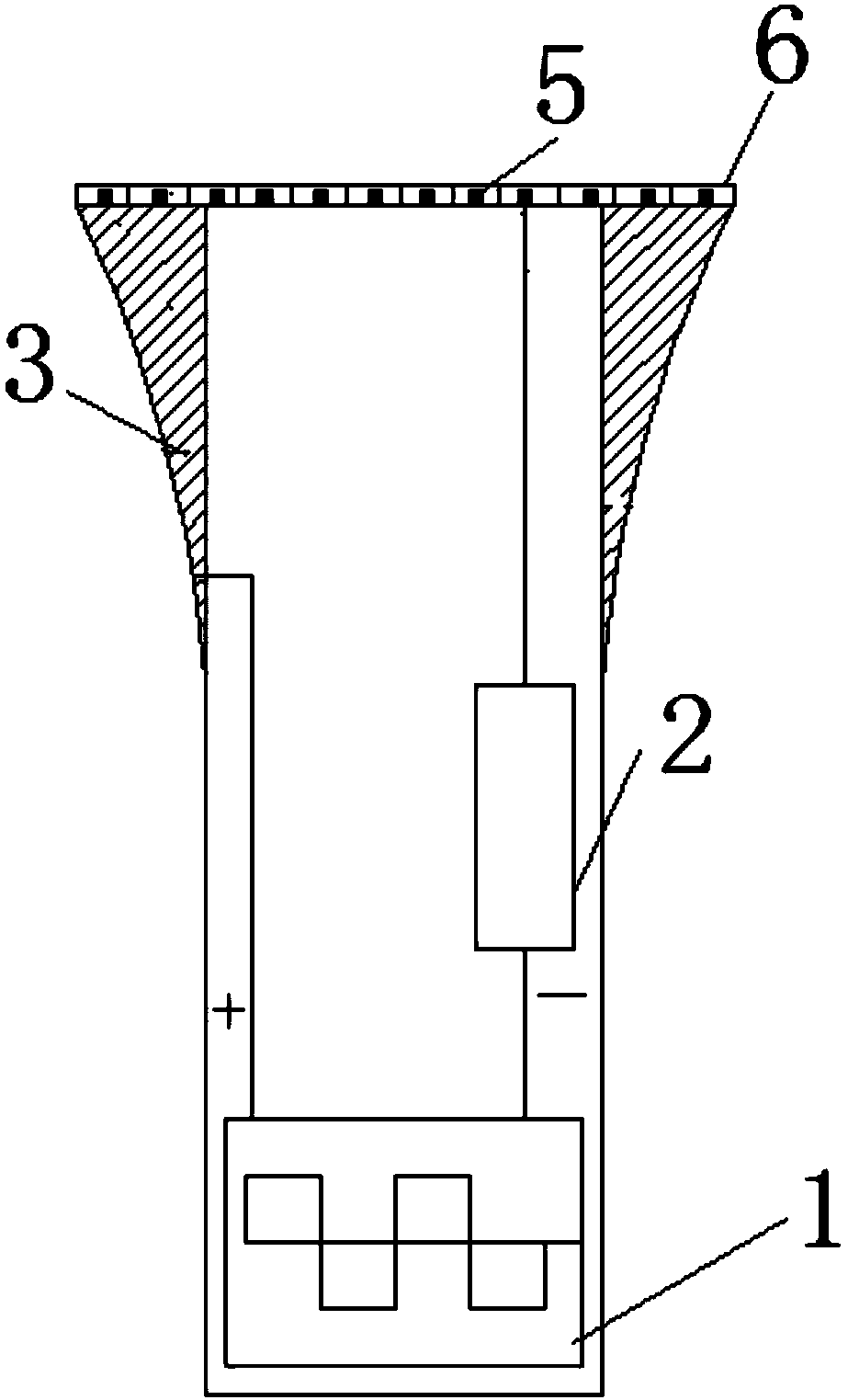

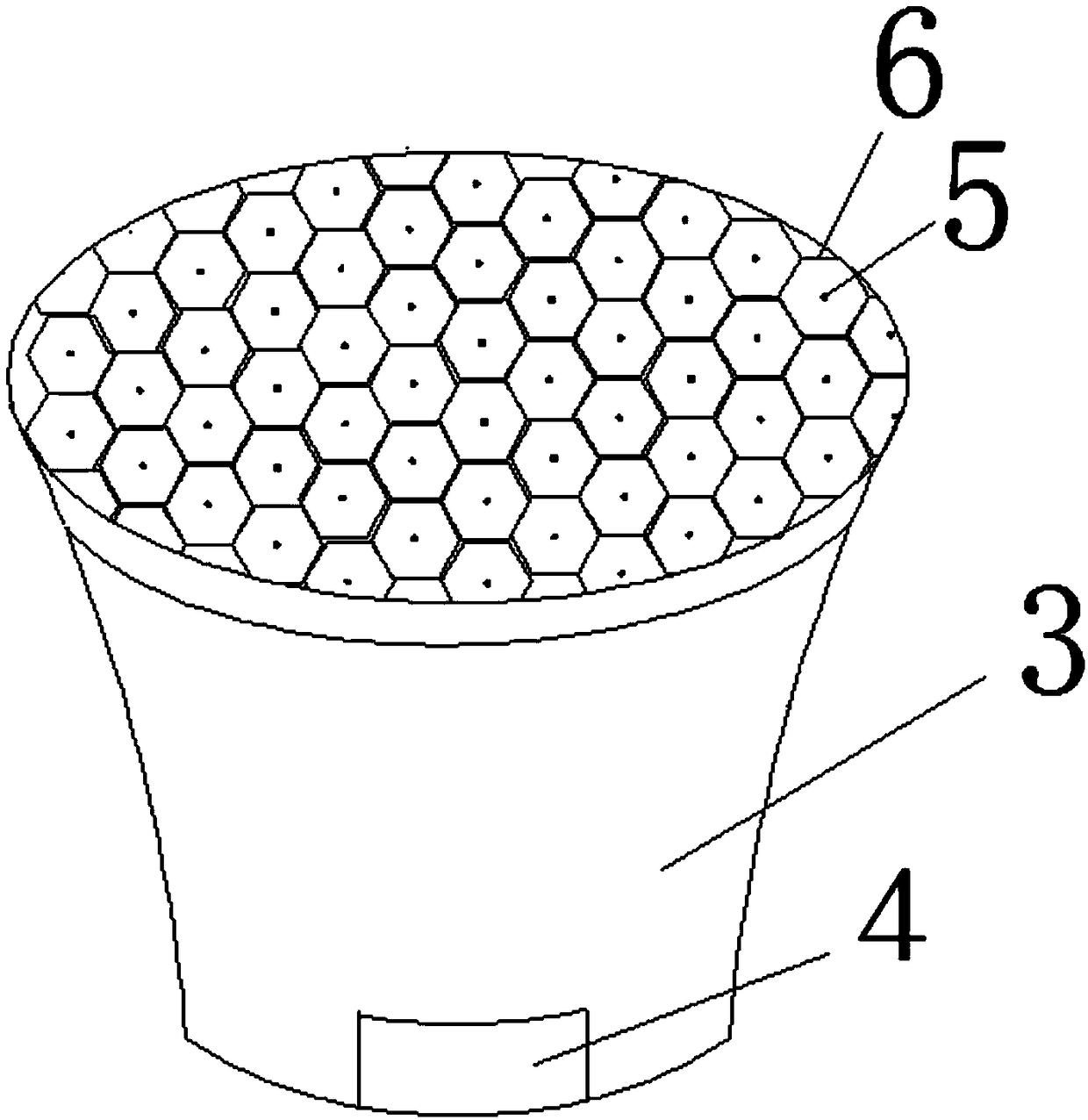

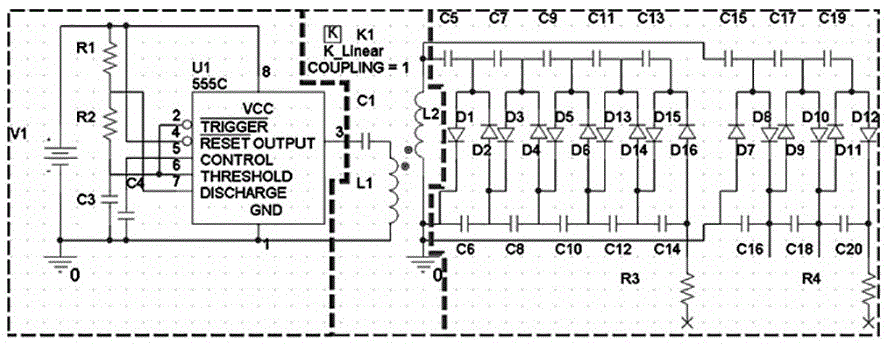

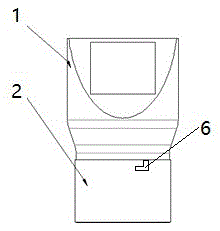

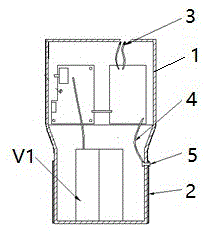

Space cleaning device with low power consumption

ActiveCN109442612AImprove cleanlinessIncrease contentMechanical apparatusElectrical apparatusHigh concentrationHazardous substance

The invention relates to a space cleaning device with low power consumption. The space cleaning device comprises a shell with an opening at the top end, an air molecular density enhancer which sleevesthe side wall, close to the top end of the shell, of the shell, an electronic emitter arranged at the top end of the shell, and a pulse power supply and a free electronic energy regulator which are arranged in an inner cavity of the shell; the air molecular density enhancer is connected with a cathode of the pulse power supply; the electronic energy regulator is connected with an anode of the pulse power supply, and the electronic emitter is connected with the electronic energy regulator. According to the space cleaning device with low power consumption, based on a principle of electron collision and conduction, negative oxygen ions with the high concentration are formed through a method that a pulse power technology is adopted to produce the negative oxygen ion concentration difference,the content of the negative oxygen ions with small particle sizes in the air is increased, the small particle sized negative oxygen ions with the high concentration can be produced at low power, an air supplying device is not required, harmful substances such as ozone nitrogen oxides are not generated, radiation is avoided, the power of the space cleaning device is small, energy is saved, and thespace cleaning ability is greatly improved.

Owner:北京嵘初科技有限公司

Water-based air purification paint and preparation method thereof

InactiveCN113122084AGood for healthTo achieve the purpose of purifying the airGas treatmentElectrostatic separationRare-earth elementPtru catalyst

A water-based air purification paint is prepared from the following components in percentage by mass: 25 to 35 percent of modified acrylic resin, 20 to 30 percent of a pigment, 10 to 20 percent of a filler, 3 to 7 percent of light rare earth elements, 1 percent of an activating agent, 0.5 percent of a catalyst and 2.5 percent of an auxiliary agent. The invention also provides a preparation method of the water-based air purification paint. The water-based air purification paint provided by the invention can maintain the existing decorative effect, eliminate harmful substances in air and increase the concentration of negative oxygen ions in air.

Owner:深圳市通晟供应链发展有限公司

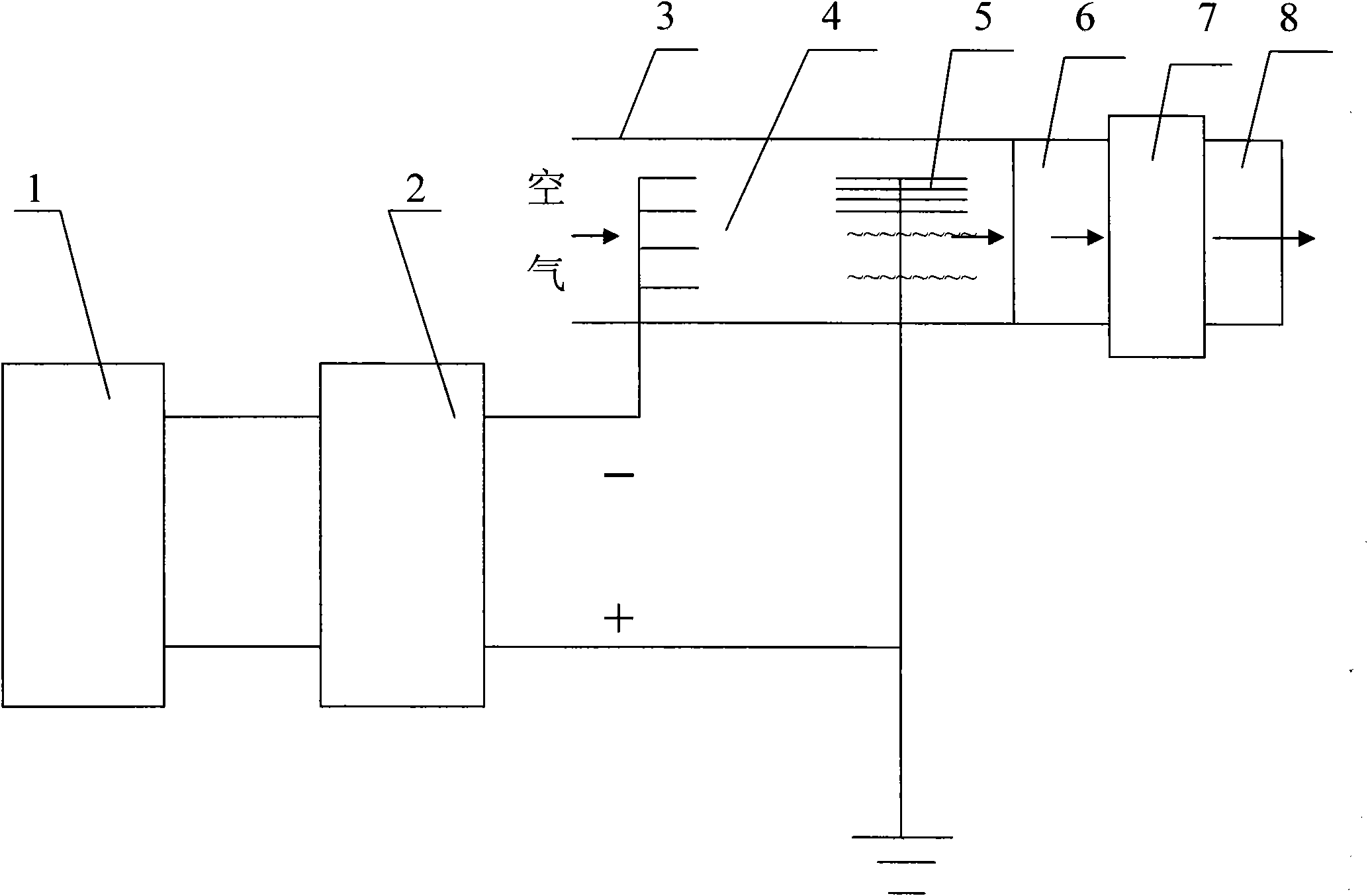

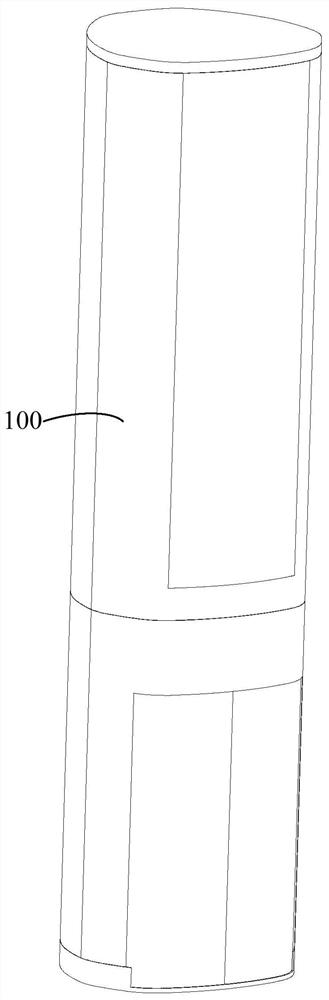

No-consumable air purifier for collecting dust in base

InactiveCN105674401AIncrease the concentration of negative oxygen ionsIncrease inhalationMechanical apparatusLighting and heating apparatusPollutantHuman health

The invention discloses a no-consumable air purifier for collecting dust in a base. The air purifier comprises a purifier body with an anion generation circuit, and a metal base for bearing the purifier body; the anion generation circuit includes a direct current-alternating current oscillation module, a high-load boosting transformer module and a multi-stage boosting module; a negative pole discharge end of the anion generation circuit is connected with a carbon brush or a metal needle; and a positive pole discharge end is connected with the metal base. The air purifier uses the carbon brush or the metal pin for forming free electrons; the electrons released in air are attached on oxygen molecules in the microsecond time to form negative oxygen ions; the negative oxygen ions are absorbed on PM2.5 or polluted particles for negative polarization, and the metal base absorbs the negatively polarized PM2.5 or polluted particles, so that the microparticles in the air are effectively eliminated, the air is purified, and the human health is protected. The metal base is not consumable, and can be termly cleaned and repeatedly used.

Owner:SUZHOU DEME ENVIRONMENTAL PROTECTION TECH CO LTD

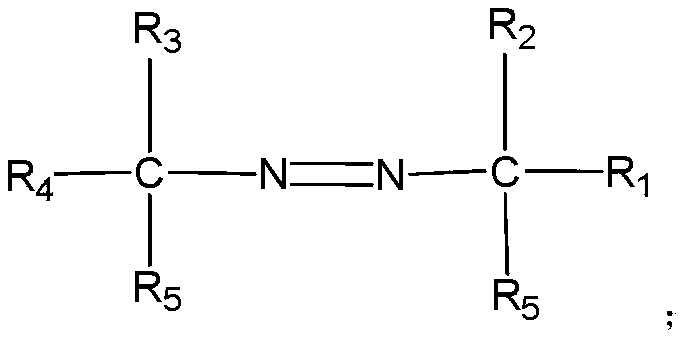

Porous nano-material and preparation method thereof

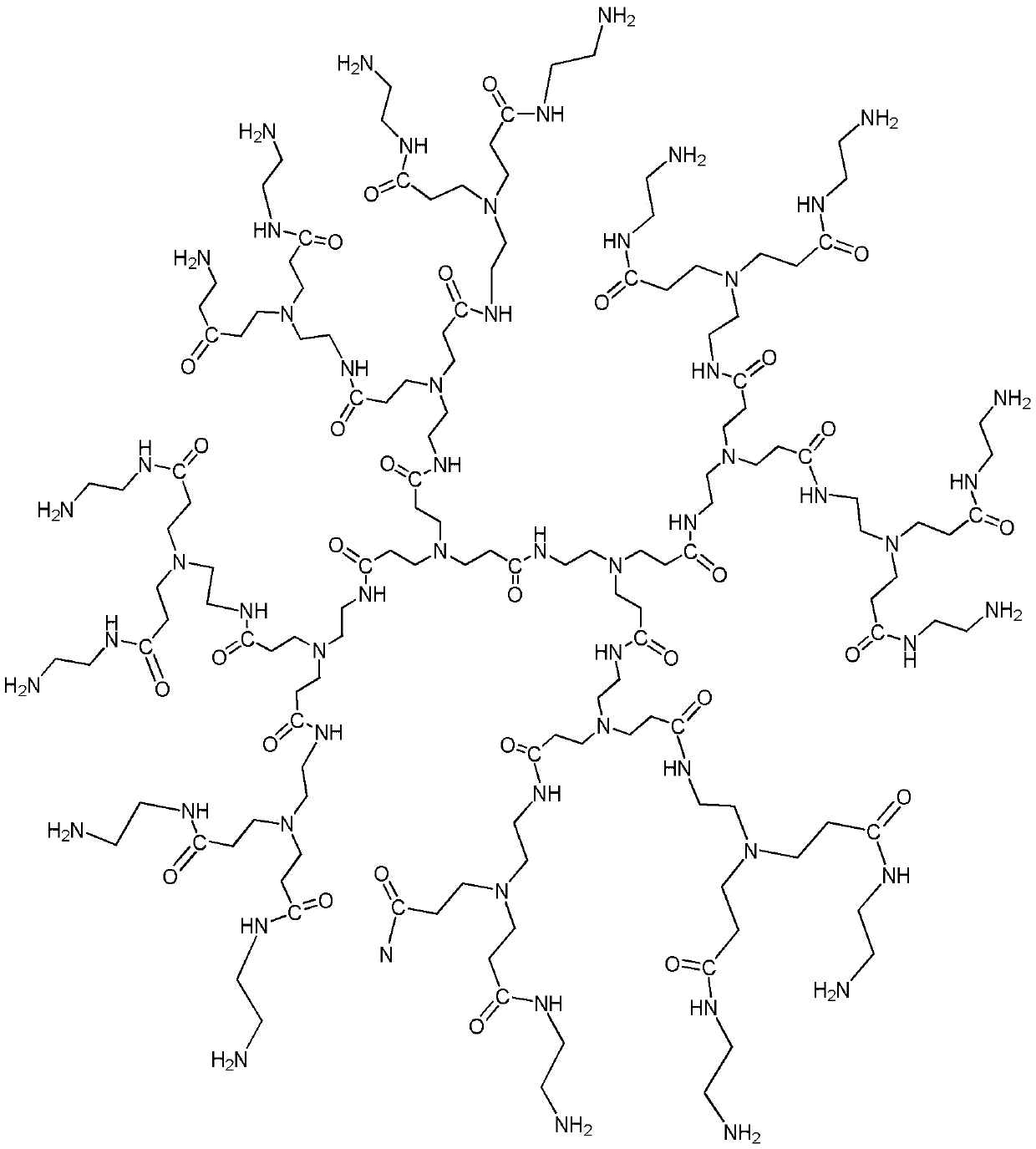

InactiveCN109745956ASimple preparation processWith adsorptionMaterial nanotechnologyOther chemical processesDendrimerToxic gas

The invention discloses a porous nano-material and a preparation method thereof. The porous nano-material comprises an azo compound, a dendrimer, a functional nano-material, a fluorescent conjugated polymer and deionized water. The preparation method includes the steps: weighing raw materials according to ratio; mixing the raw materials; performing ultrasonic treatment after mixing; adding the rawmaterials into a reactor for reaction; cooling, centrifuging, washing, drying and calcining the raw materials to obtain the porous nano-material. The preparation technology is simple, the prepared porous nano-material has the functions of adsorption, bacteria resisting, odor removing and the like, generated negative oxygen ions can react with harmful gas such as formaldehyde and methylbenzene inair, toxic gas can be thoroughly decomposed as the dendrimer is combined with the azo compound, and purification efficiency is improved. The fluorescent conjugated polymer is assembled on a graphene oxide slice layer, and harmful bacteria are killed in the air purification process.

Owner:苏州逸纪杰电子科技有限公司

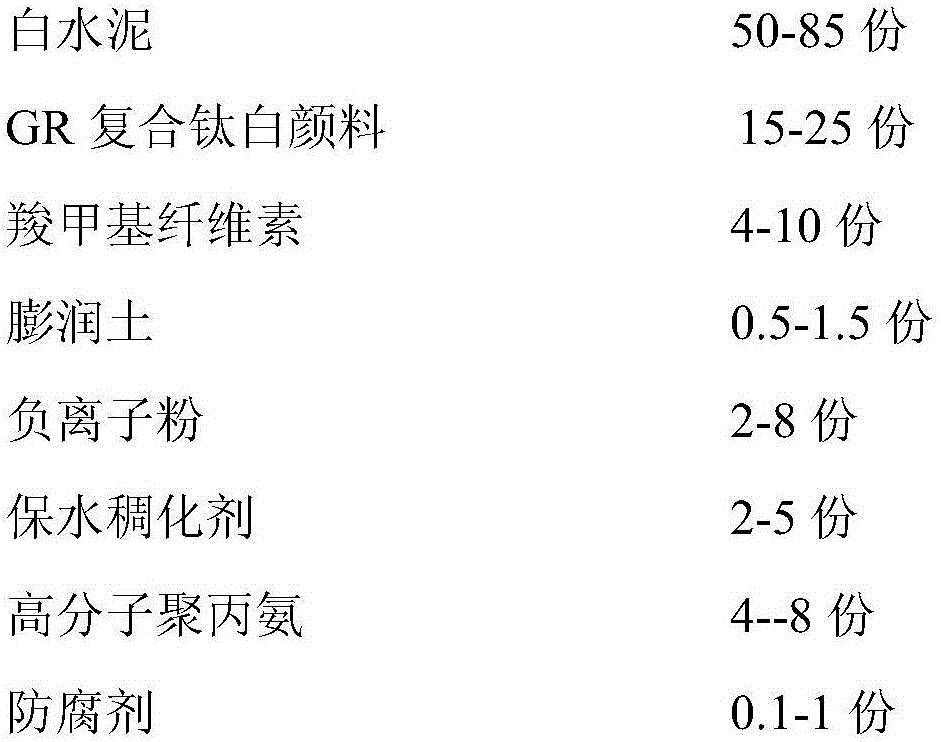

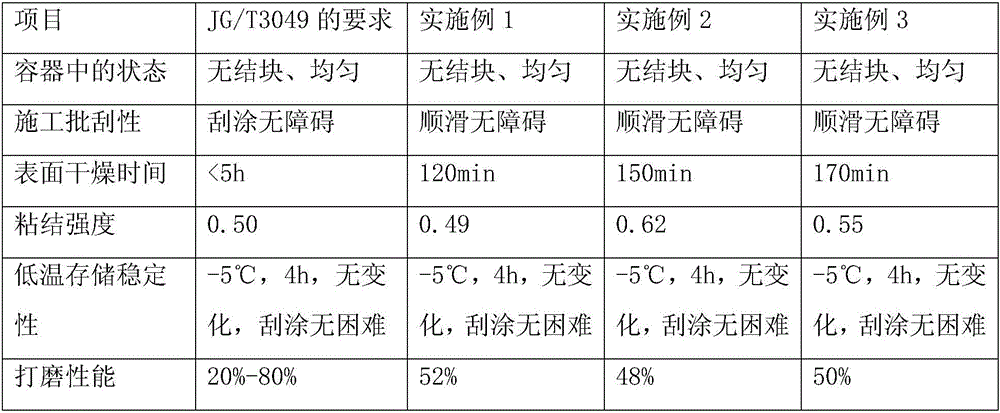

Environment-friendly water-resistant interior wall putty

The invention relates to a construction decoration material, particularly to an environment-friendly water-resistant interior wall putty powder. The environment-friendly water-resistant interior wall putty powder comprises the following components: 50 to 85 parts of white cement, 15 to 25 parts of GR compound titanium oxide pigment, 4 to 10 parts of carboxymethylcellulose, 0.5 to 1.5 parts of bentonite, 2 to 8 parts of negative ion powder, 2 to 5 parts of a water-retaining thickening agent, 4 to 8 parts of high-polymer polypropylene ammonia and 0.1 to 1 part of a preservative. The environment-friendly water-resistant interior wall putty is simple in ingredient, environment-friendly, capable of optimizing environment, good in water resistance, easy to construct and low in cost.

Owner:杭州唯曦科技有限公司

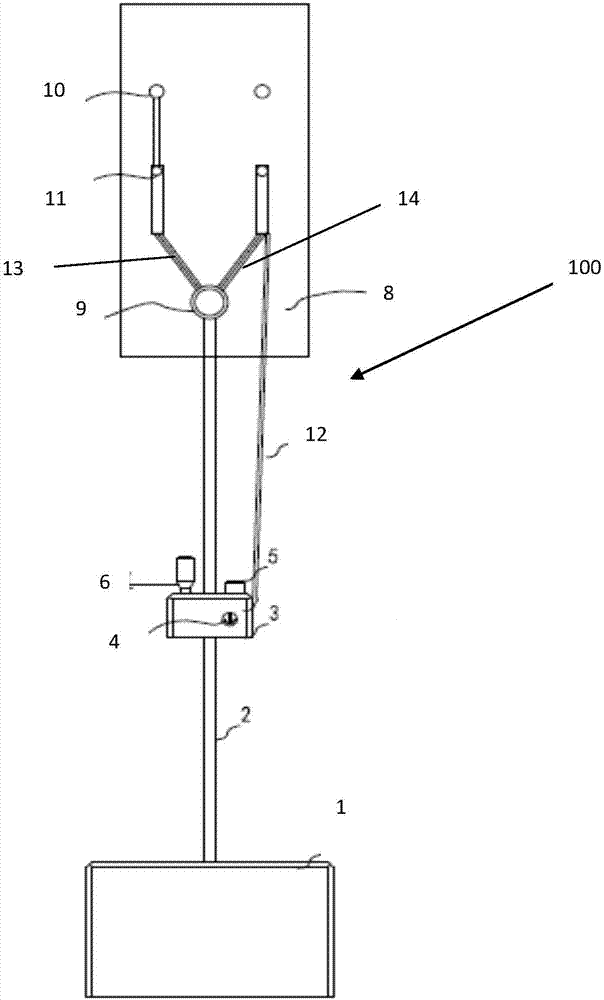

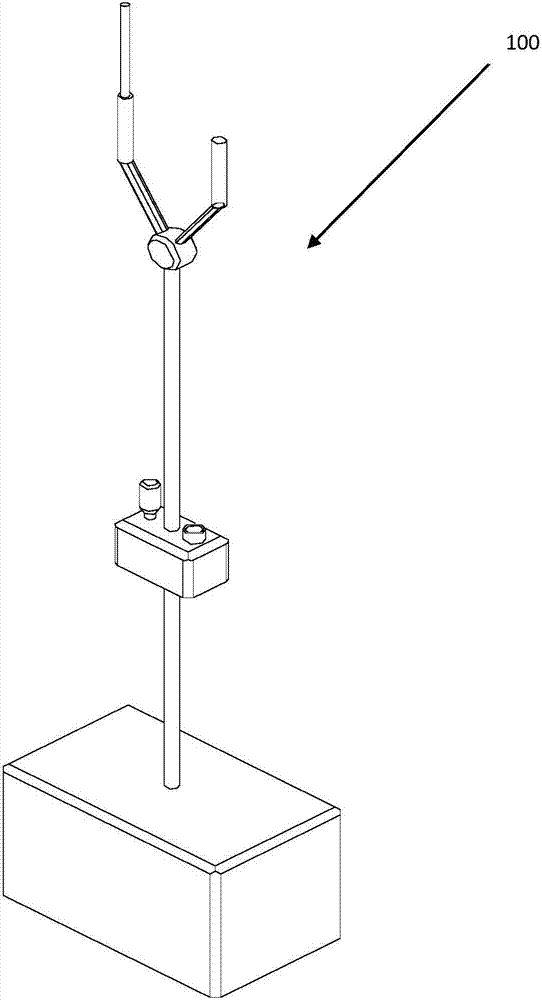

Negative oxygen ion generation device

InactiveCN106949578ASolve the problem of dry and wet balanceIncrease oxygen contentMechanical apparatusLighting and heating apparatusWater sourceOxygen ions

A negative oxygen ion generation device comprises an oxygen output device connected with an oxygen source and an atomization device connected with a water source. The negative oxygen ion generation device is characterized in that the atomization device is provided with a fountain or waterfall simulation device; and the oxygen output device conveys oxygen to the position nearby the simulation device.

Owner:王宝光

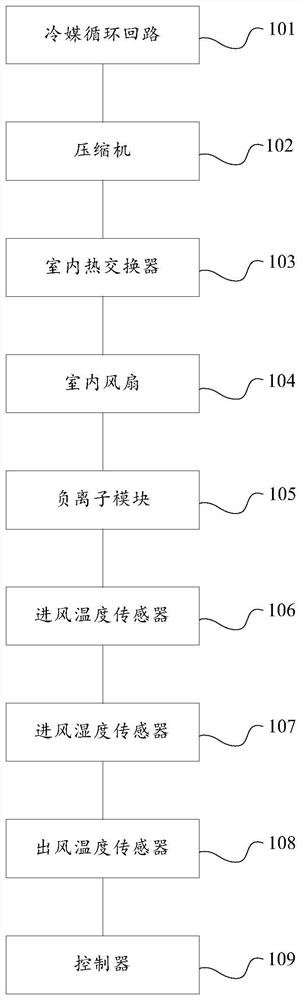

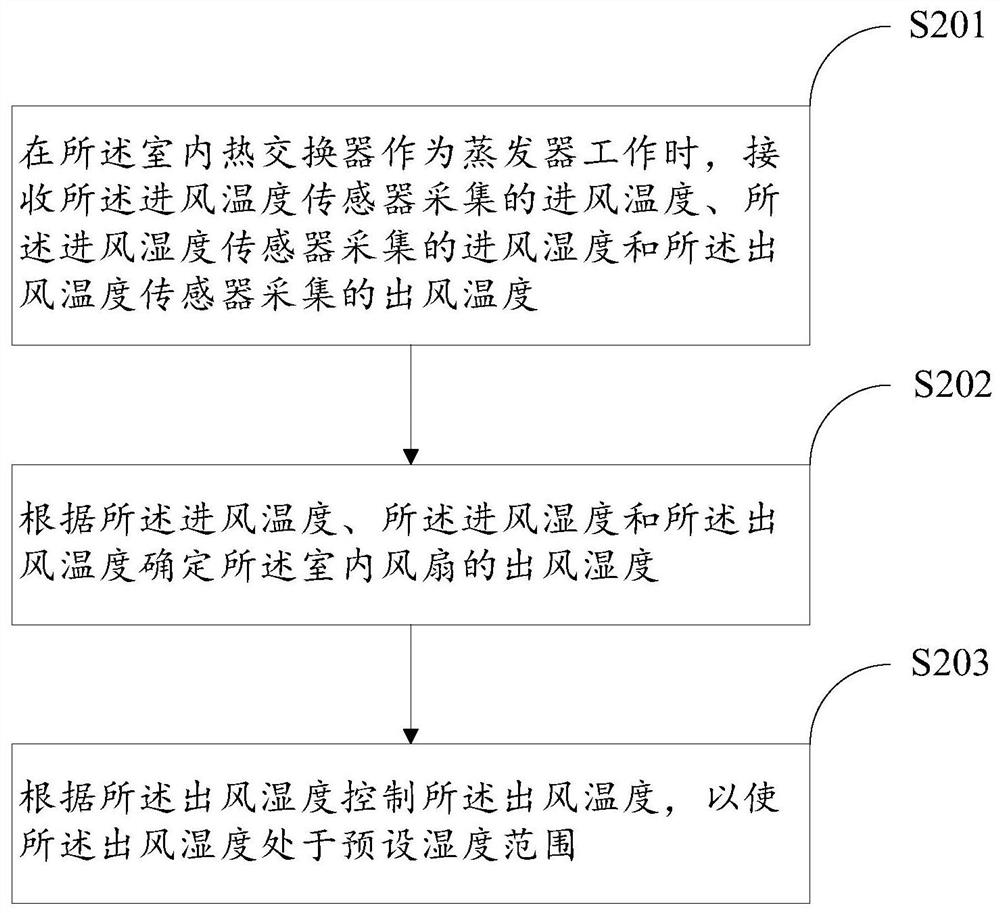

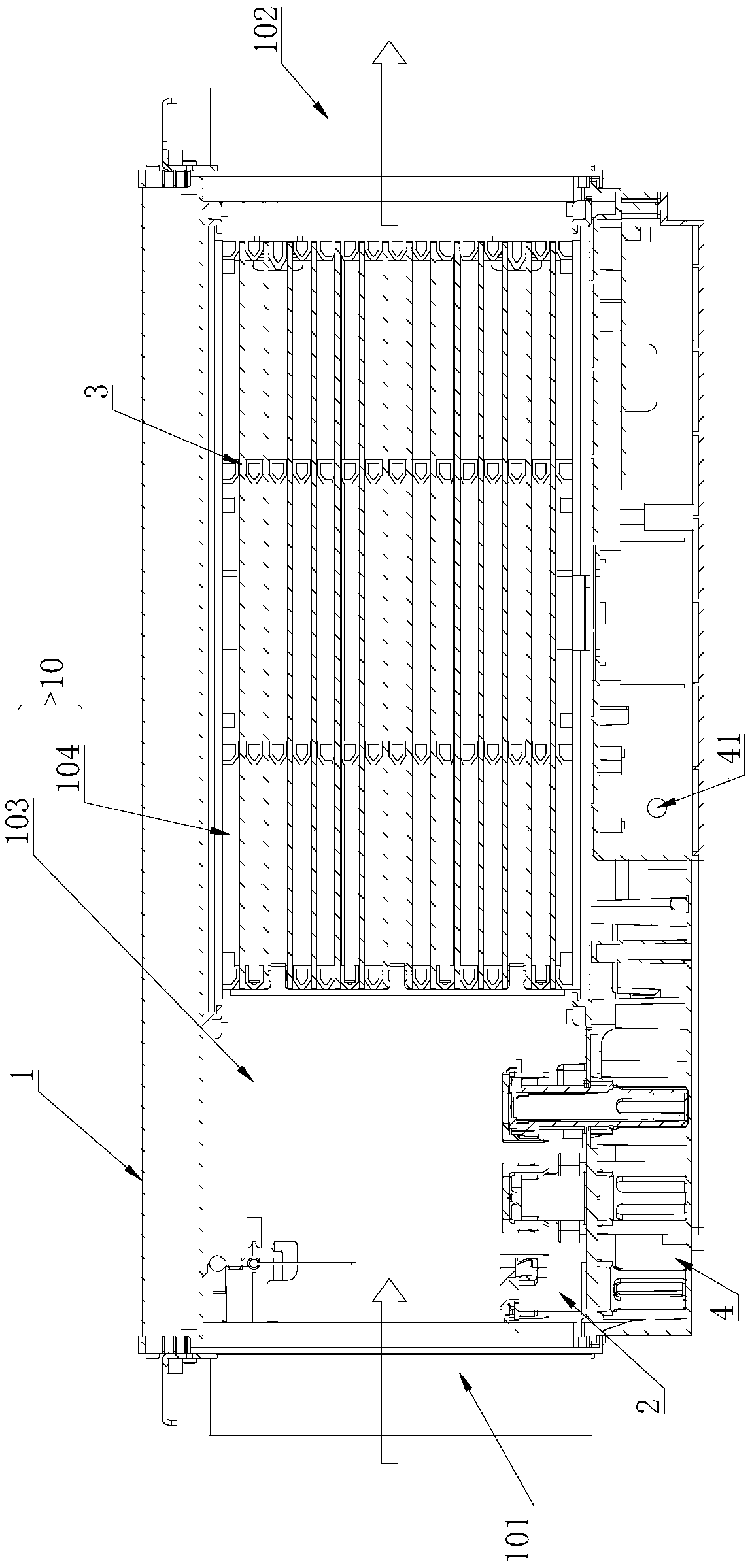

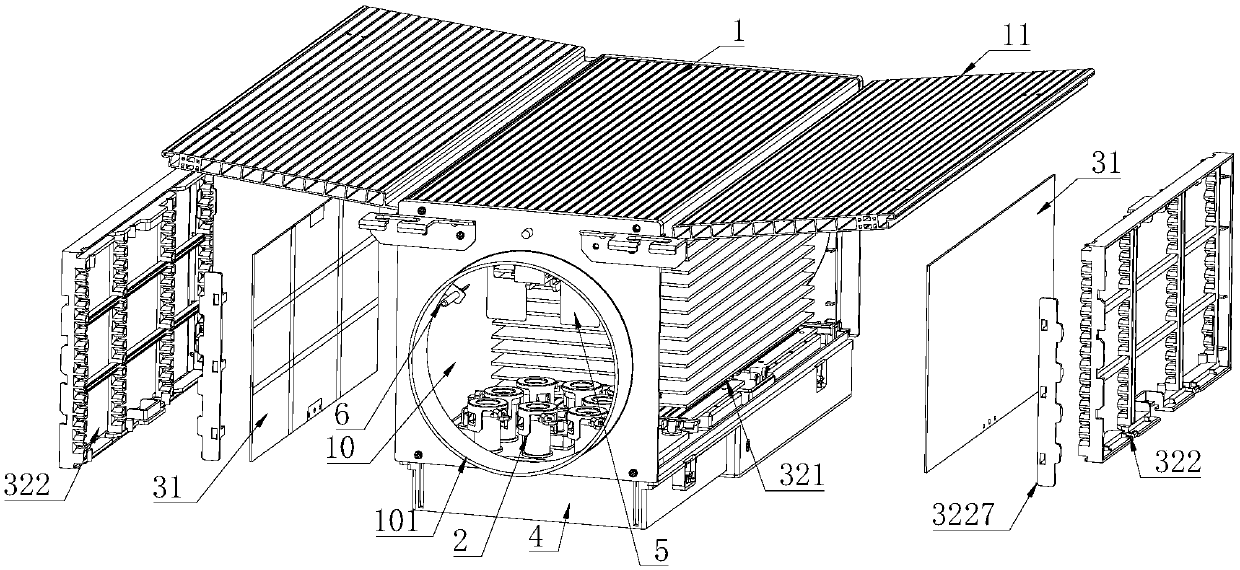

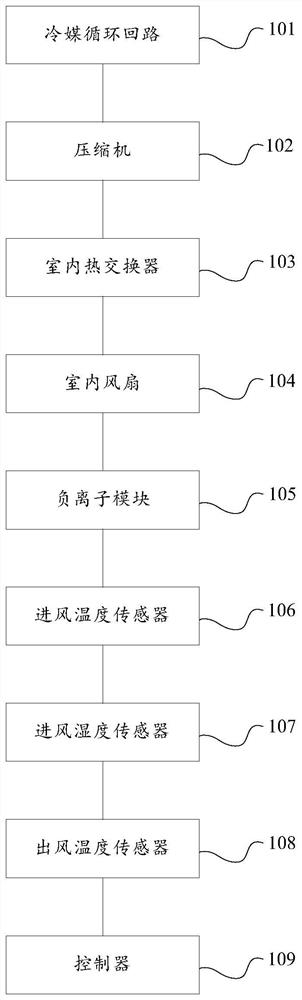

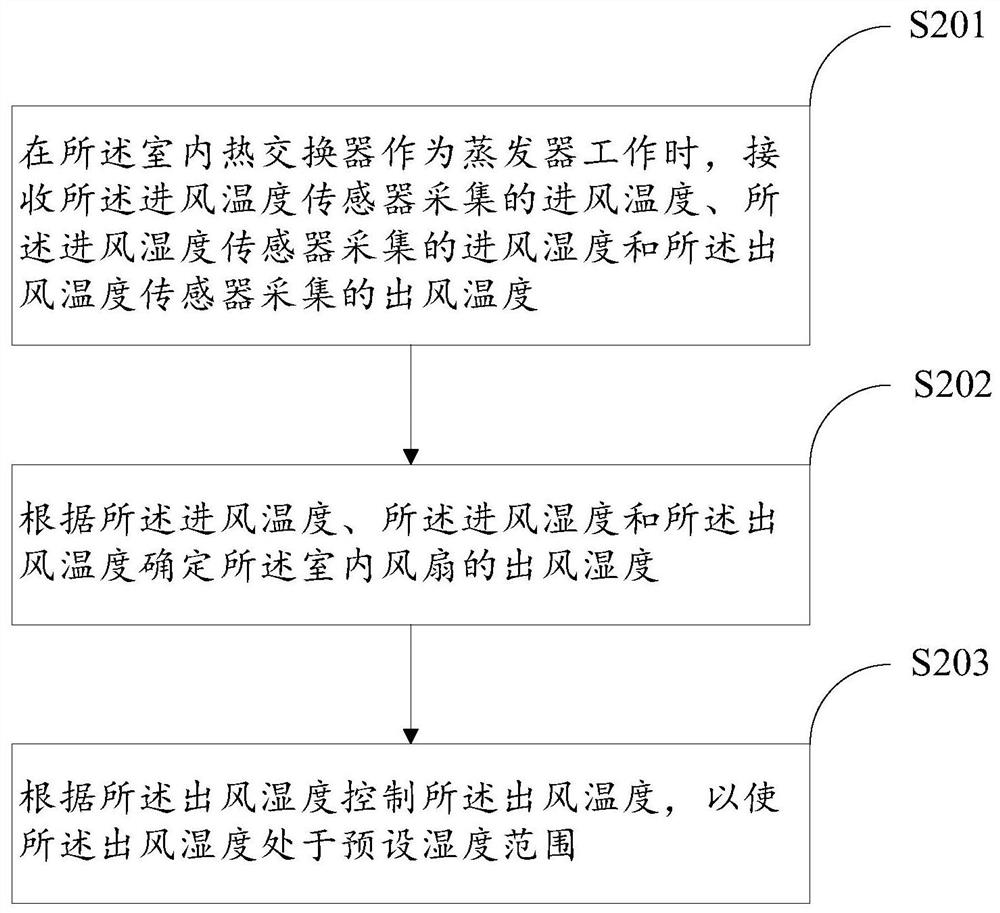

Air conditioner and control method

ActiveCN111912076AImprove work efficiencyIncrease the concentration of negative oxygen ionsMechanical apparatusSpace heating and ventilation safety systemsMechanical engineeringMechanics

The invention discloses an air conditioner and a control method. The air conditioner comprises a refrigerant circulation loop, a compressor, an indoor heat exchanger, an indoor fan, a negative ion module, an air inlet temperature sensor, an air inlet humidity sensor, an air outlet temperature sensor and a controller. The controller is configured to receive an air inlet temperature collected by theair inlet temperature sensor, air inlet humidity collected by the air inlet humidity sensor and an air outlet temperature collected by the air outlet temperature sensor when the indoor heat exchangerworks as an evaporator. The air outlet humidity of the indoor fan is determined according to the air inlet temperature, the air inlet humidity and the air outlet temperature. The air outlet temperature is controlled according to the air outlet humidity, so that the air outlet humidity is within a preset humidity range, the negative ion module achieves optimal working efficiency, and negative oxygen ion concentration of indoor air is rapidly increased.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

Light-oil for releasing negative ions and preparation method thereof

The invention discloses light-oil for releasing negative ions and a preparation method thereof, the light-oil for releasing the negative ions is mainly composed of a mixture of 35 to 45 parts of negative ion powder and 95 to 105 parts of LED light-oil, the preparation method comprises the following steps: S1, preparing the negative ion powder and the LED light-oil; S2, heating the LED light-oil prepared in the step S1 in water bath for thermal insulating; S3, placing the negative ion powder S1 prepared in the step S1 in the LED light-oil in the S2, stirring, to fully mix the negative ion powder and the LED light-oil to obtain the light-oil with the negative ion powder. The light-oil is used to coat the surface of an object to radiate air. The air is ionized to release negative oxygen ionsto remove formaldehyde in a room, so that the indoor air is purified, the content of the formaldehyde in the air is reduced, and the negative oxygen ions are provided for the indoor environment, thereby creating a healthy environment for people.

Owner:成都韩尚艺术贴花有限公司

Air purifying device and air purifying method

PendingCN111102659AIncrease the concentration of negative oxygen ionsEasy to excludeMechanical apparatusLighting and heating apparatusAir decontaminationHazardous substance

The invention discloses an air purifying device. The air purifying device comprises a shell, an air inlet and an air outlet are formed in the shell, the inside of the shell is hollow, and an air channel is formed in the shell. The air channel extends to communicate the air inlet with the air outlet, a negative oxygen ion intensifier and a negative oxygen module are arranged in the air channel fromthe air inlet to the air outlet, the negative oxygen ion intensifier atomizes and humidifies air flowing through the air channel so as to remove large-particle dust in the air, and the negative oxygen module increases negative oxygen ions in the air. The invention further discloses an air purifying method. The air is effectively purified. The air is humidified and dedusted first, the concentration of the negative oxygen ions is increased through the negative oxygen module, harmful substances in the air are chemically decomposed, and it is achieved the indoor air is purified.

Owner:桂勇

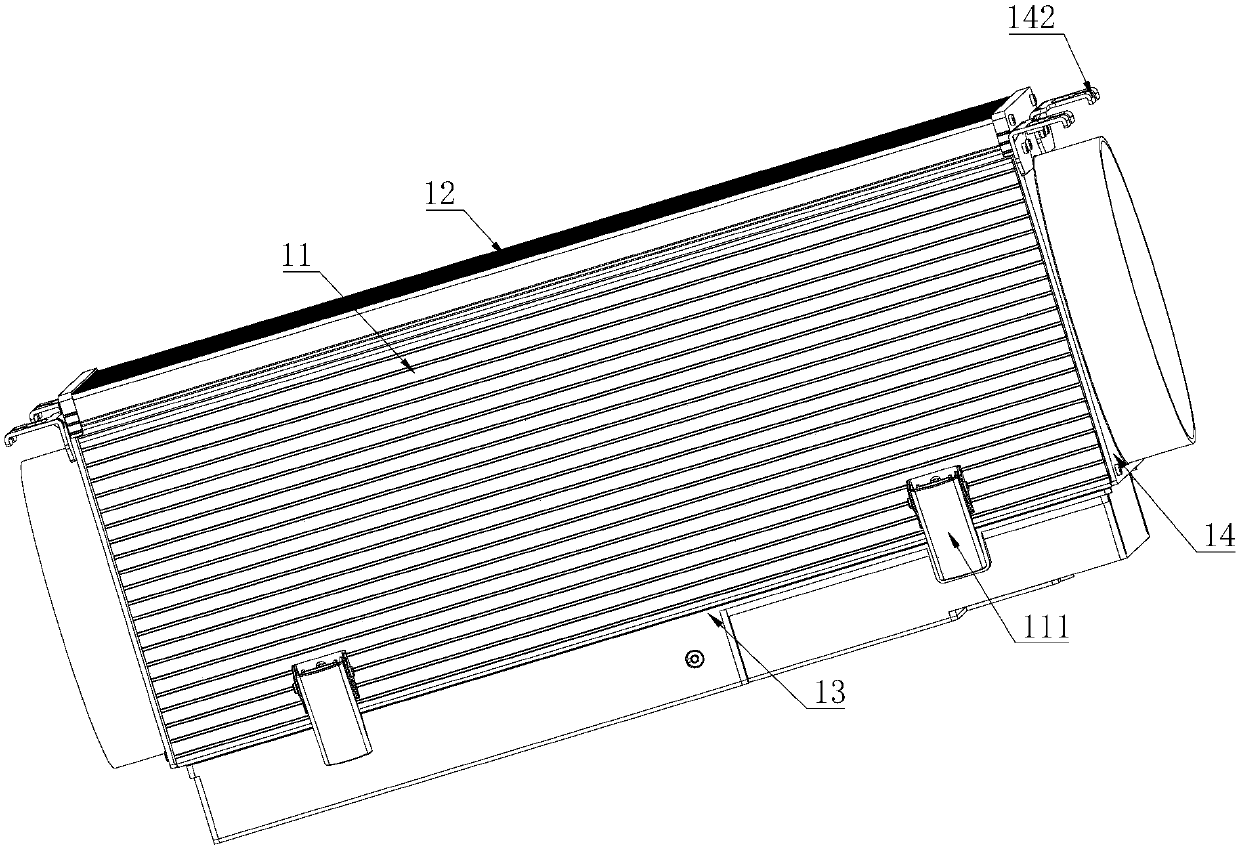

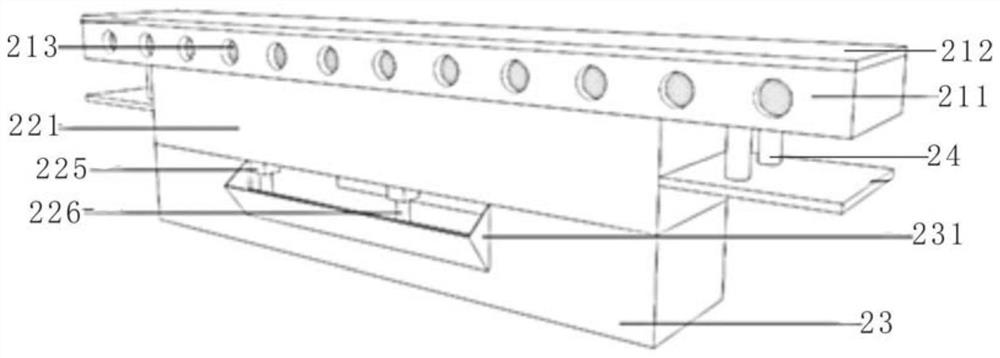

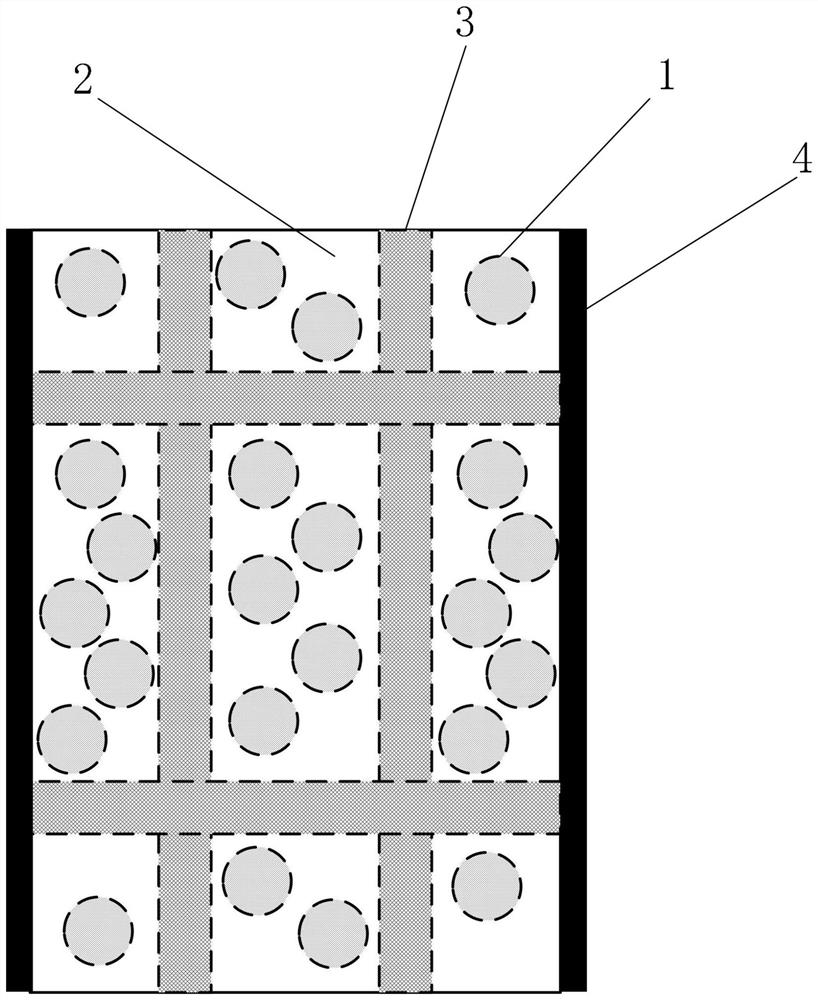

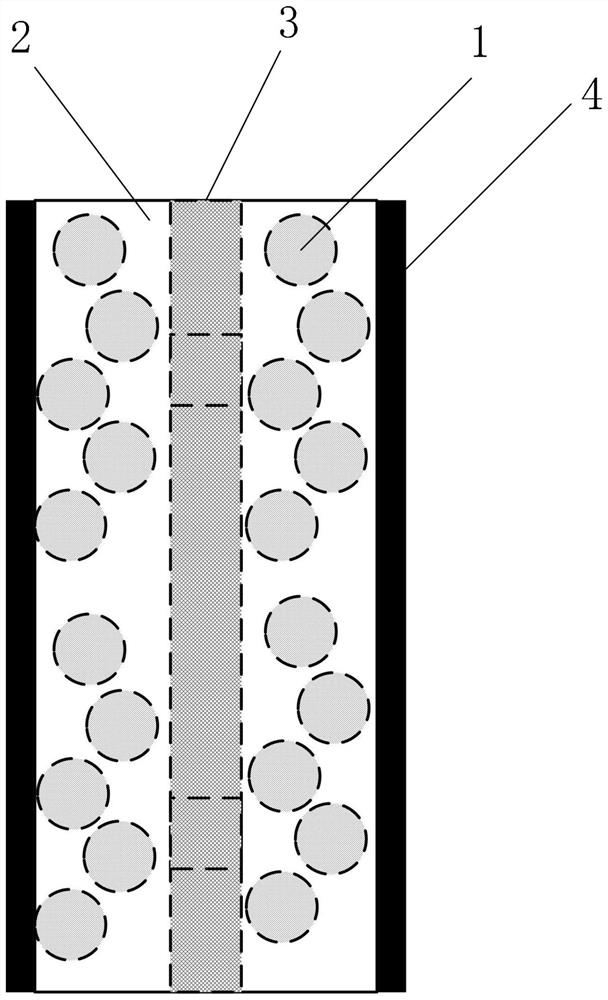

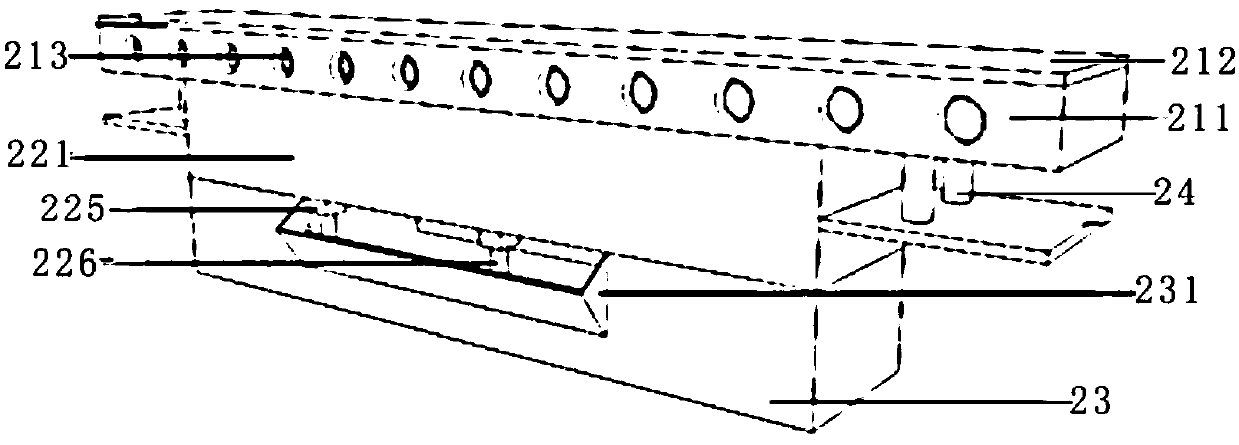

Heat exchange device for fresh air ventilator

PendingCN107270501AIncrease the concentration of negative oxygen ionsImprove efficiencyEnergy recovery in ventilation and heatingLighting and heating apparatusHazardous substanceFresh air

The invention discloses a heat exchange device for a fresh air ventilator. The heat exchange device for the fresh air ventilator comprises a shell, an outdoor air inlet, a fresh air outlet, a contaminated air inlet and a contaminated air outlet, wherein the outdoor air inlet, the fresh air outlet, the contaminated air inlet and the contaminated air outlet are formed in the shell. A heat exchange tank which communicates the outdoor air inlet with the fresh air outlet is arranged in the shell. A heat exchange pipe is arranged in the heat exchange tank. The outer surface of the heat exchange pipe is provided with an ultraviolet ray emitting component and coated with a photocatalyst sterilization layer. The two ends of the heat exchange pipe communicate with the contaminated air inlet and the contaminated air outlet correspondingly. The fresh air outlet is connected with a gas pipeline. The end face of one end of the gas pipeline is provided with an annular groove. The end face of the other end of the gas pipeline and the end face of the fresh air outlet are provided with annular protrusions. The inner side wall and the outer side wall of the protrusions are provided with limiting rings. The groove is matched with the protrusions. The outer wall of the heat exchange pipe is coated with a photocatalyst sterilization layer and provided with a light source, so that harmful substances like various bacteria and germs in fresh air are killed. Compared with a device with a single photocatalyst sterilization layer, the heat exchange device for the fresh air ventilator has a better purification effect.

Owner:SICHUAN JIANYUAN ENERGY SAVING TECH CO LTD

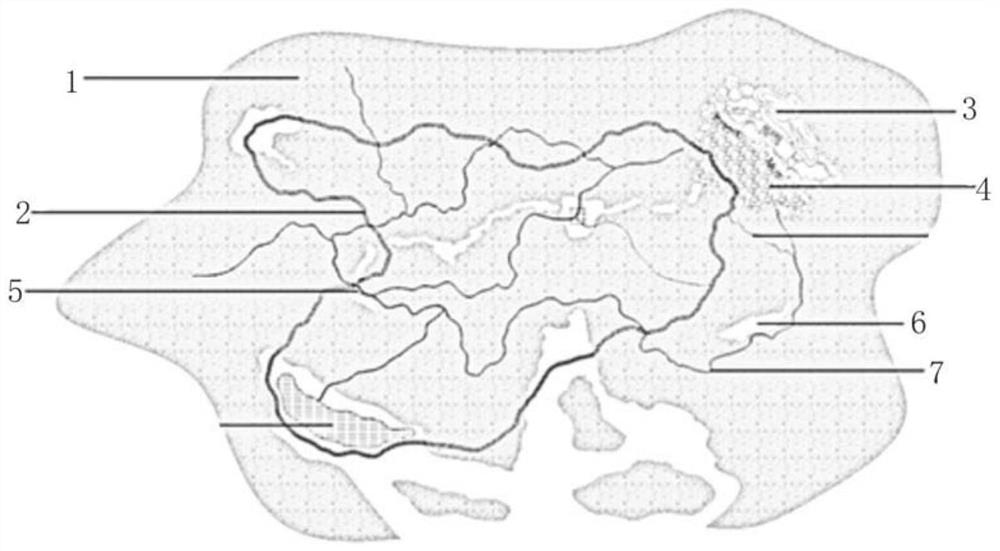

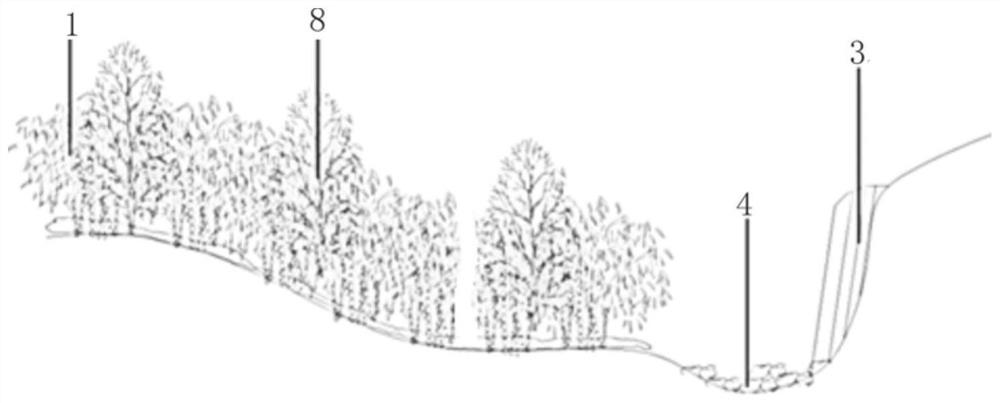

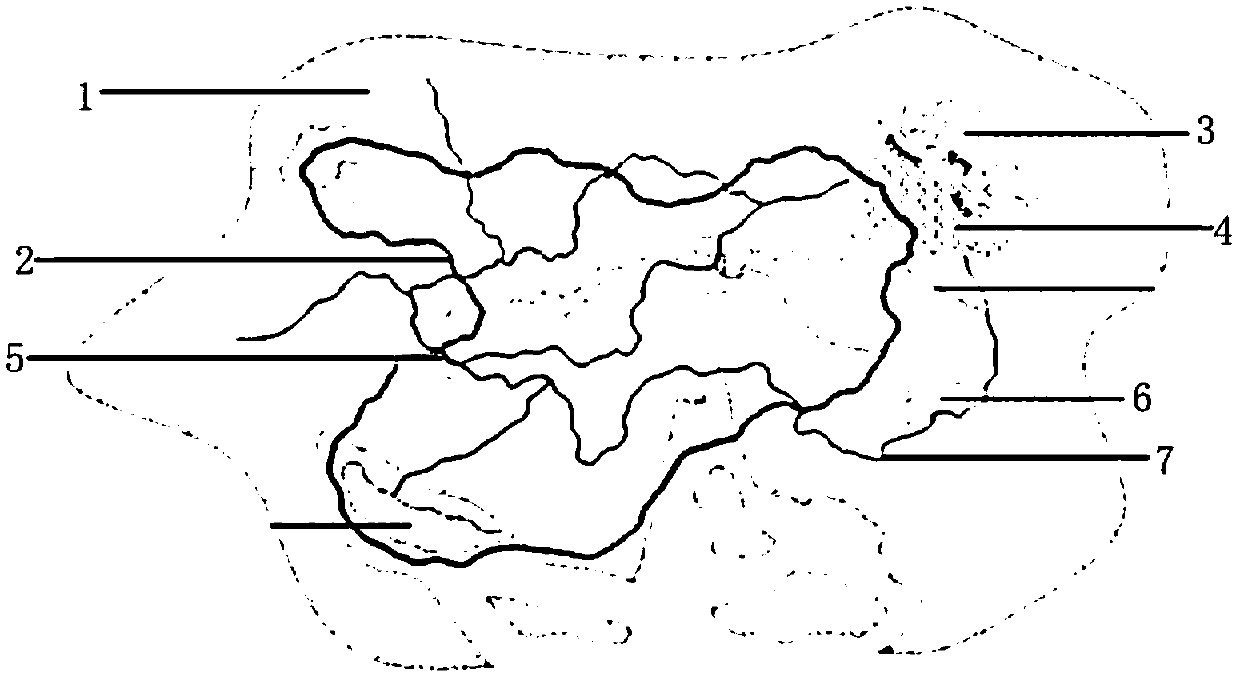

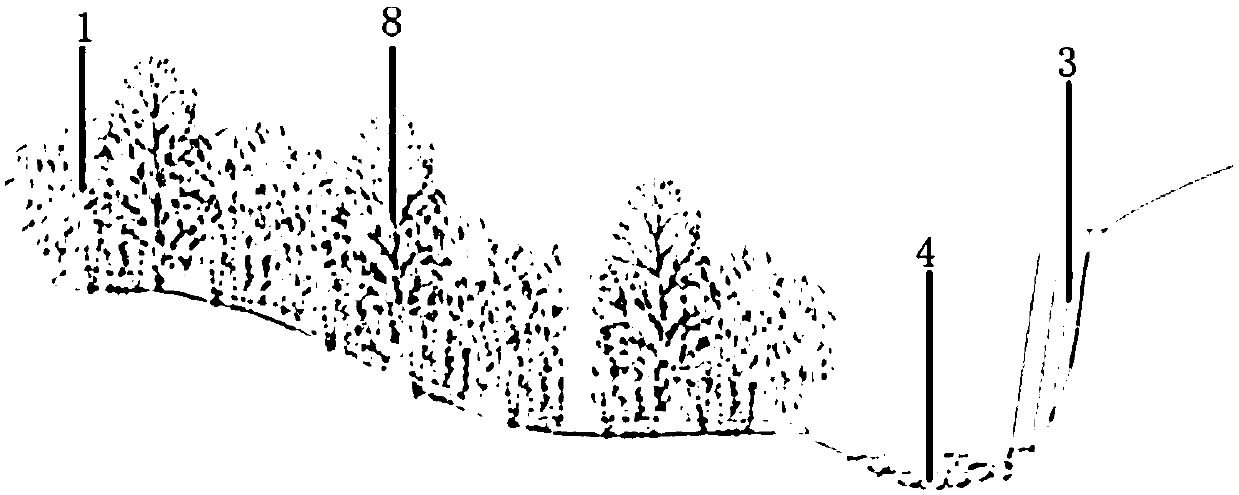

Construction method of moso bamboo forest health care system

ActiveCN109673406BIncrease the concentration of negative oxygen ionsIncrease biodiversityPlant cultivationCultivating equipmentsEcologyPhyllostachys

The invention discloses a construction method of a health preservation system for a phyllostachys pubescens forest. The construction method comprises the following steps: selecting a phyllostachys pubescens forest with a preset area; constructing at least one health preservation footpath around the phyllostachys pubescens forest, wherein the phyllostachys pubescens forest is capable of generatingnegative oxygen ions, the gradient of the health preservation footpath is less than 8%, and the width is more than 1.2m; planting arbors in the phyllostachys pubescens forest in a mixed manner, and planting shade-enduring shrubs and / or shade-enduring and officinal herbs in the phyllostachys pubescens forest along the terrain, wherein the planting area of the arbors is less than 25% of the total area of the phyllostachys pubescens forest, and the total canopy density of the phyllostachys pubescens forest in which the arbors are planted in a mixed manner is 0.6-0.9; and constructing waterscapes,buildings and a plurality of open spaces in the phyllostachys pubescens forest, wherein the area of the waterscapes is 20%-30% of the total area of the phyllostachys pubescens forest, and the area ofthe buildings is less than 0.5% of the total area of the phyllostachys pubescens forest.

Owner:SICHUAN AGRI UNIV

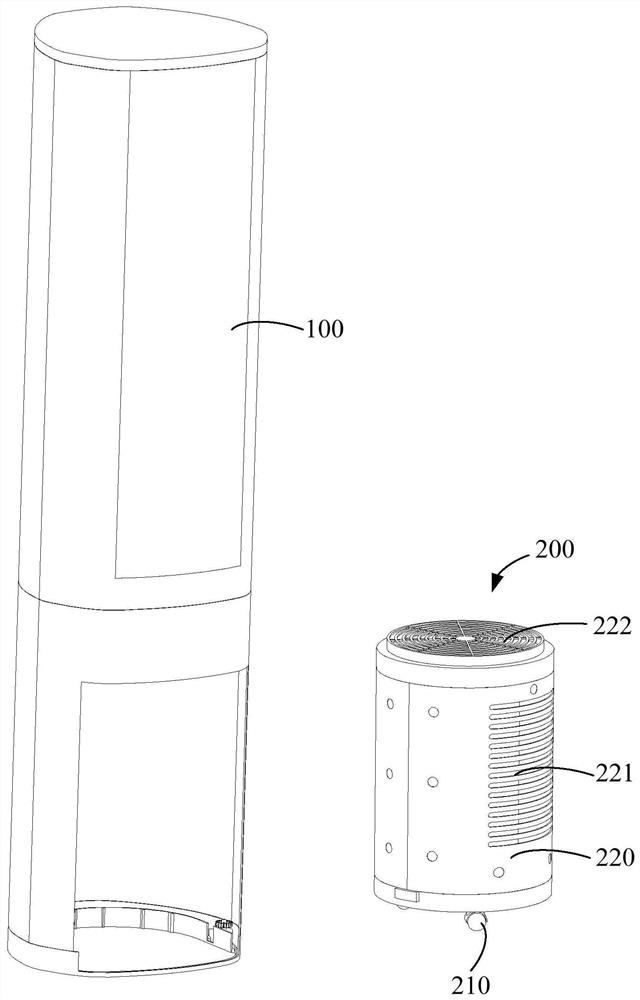

Floor type air conditioner indoor unit, control method thereof and air conditioner

PendingCN114234291AIncrease concentrationImprove air freshnessDucting arrangementsMechanical apparatusPhysicsBreathing

The invention discloses a floor type air conditioner indoor unit, a control method thereof and an air conditioner, and the floor type air conditioner indoor unit comprises a main unit, a sub-unit, an oxygen generation module and an ion generator; the host comprises an indoor heat exchange module; the sub-machine is separably connected to the main machine, and when the sub-machine is separated from the main machine, the sub-machine can work independently; the oxygen generation module is used for generating oxygen; the ion generator is used for generating anions; wherein the oxygen generation module and / or the ion generator are / is installed on the sub-machine. According to the floor type air conditioner indoor unit, the negative oxygen ion generation area is flexible and changeable, the negative oxygen ion concentration of the position where a user is located can be improved in real time, and therefore the air freshness of the position where the user is located is improved, the actual using effect of negative oxygen ions is improved to the maximum extent, and the breathing environment of the user is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

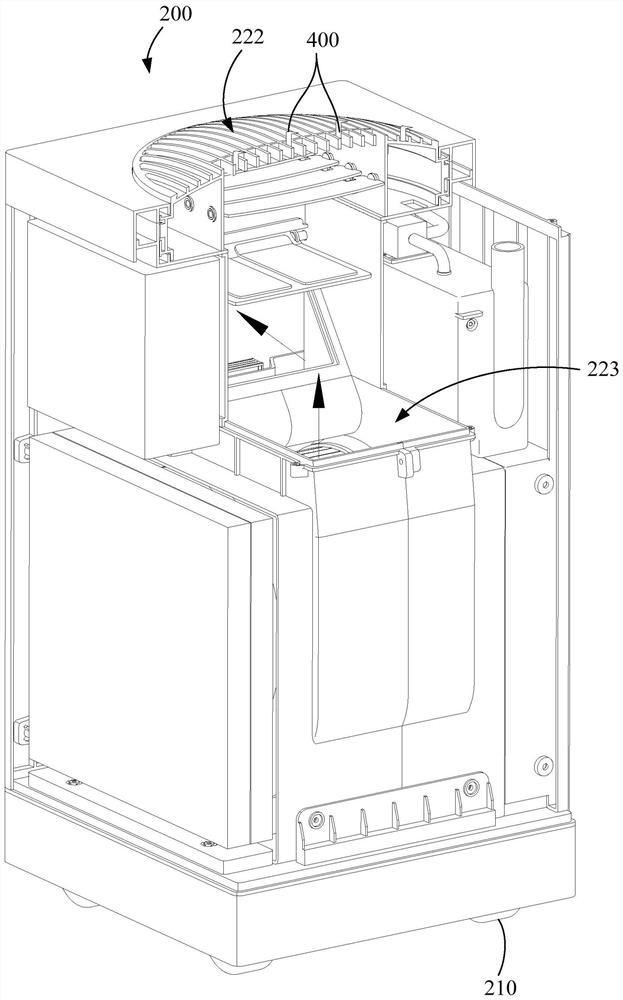

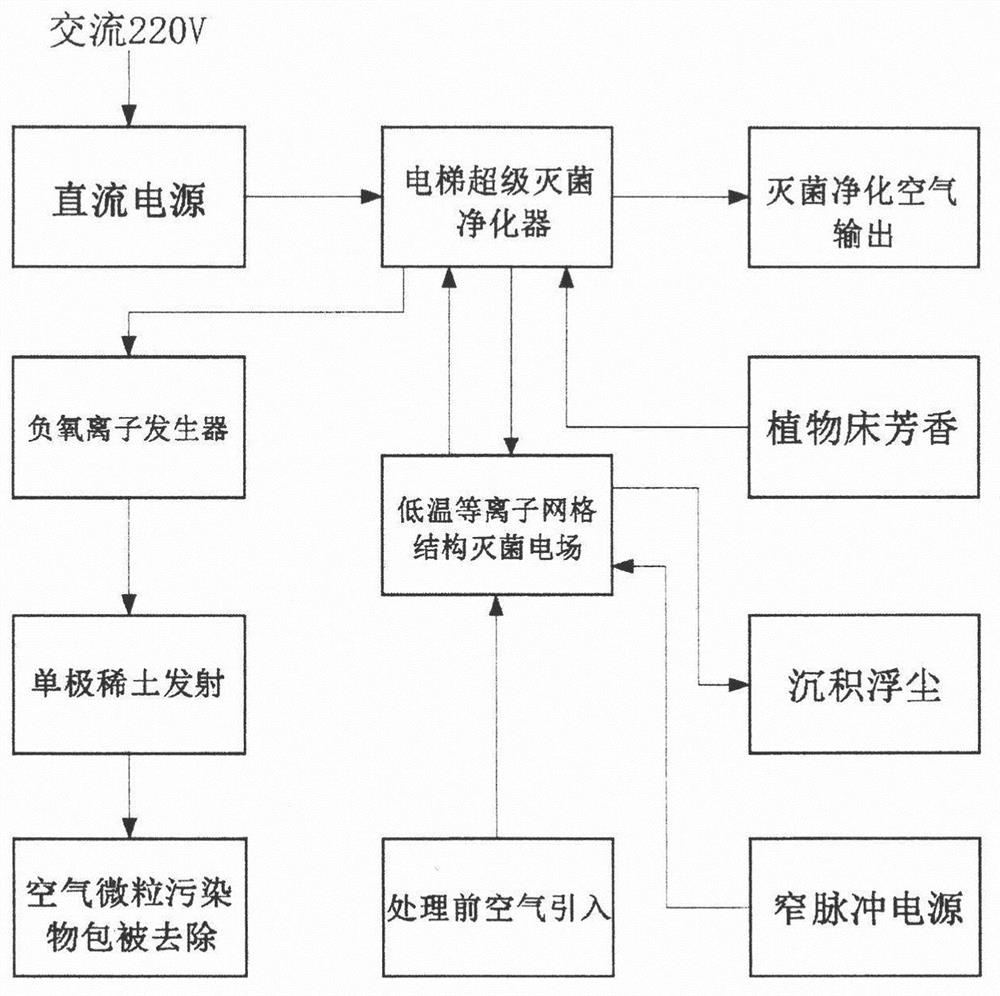

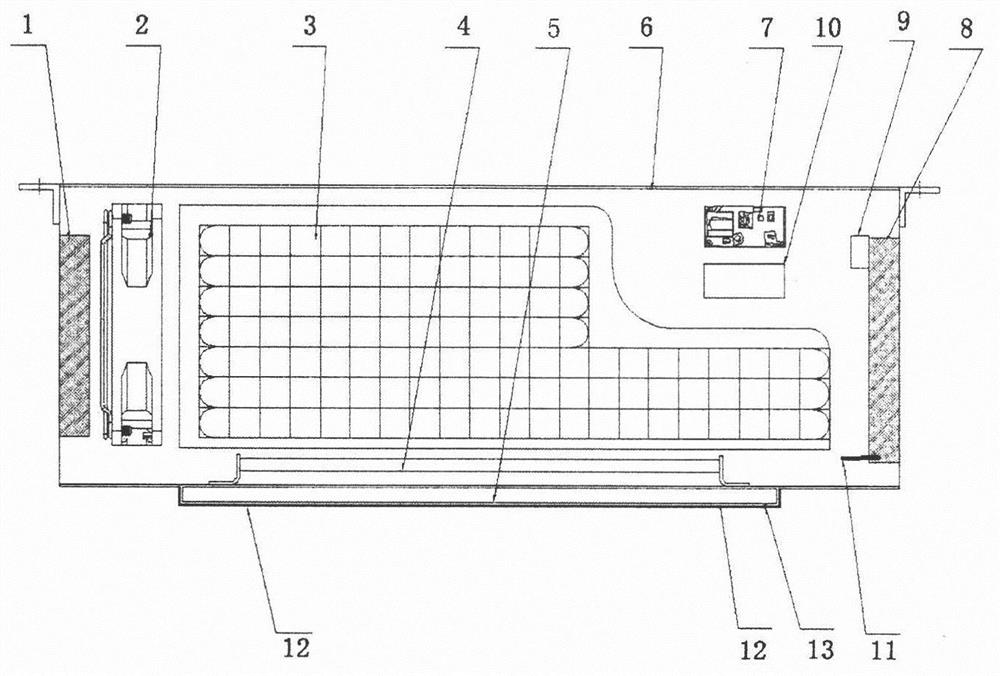

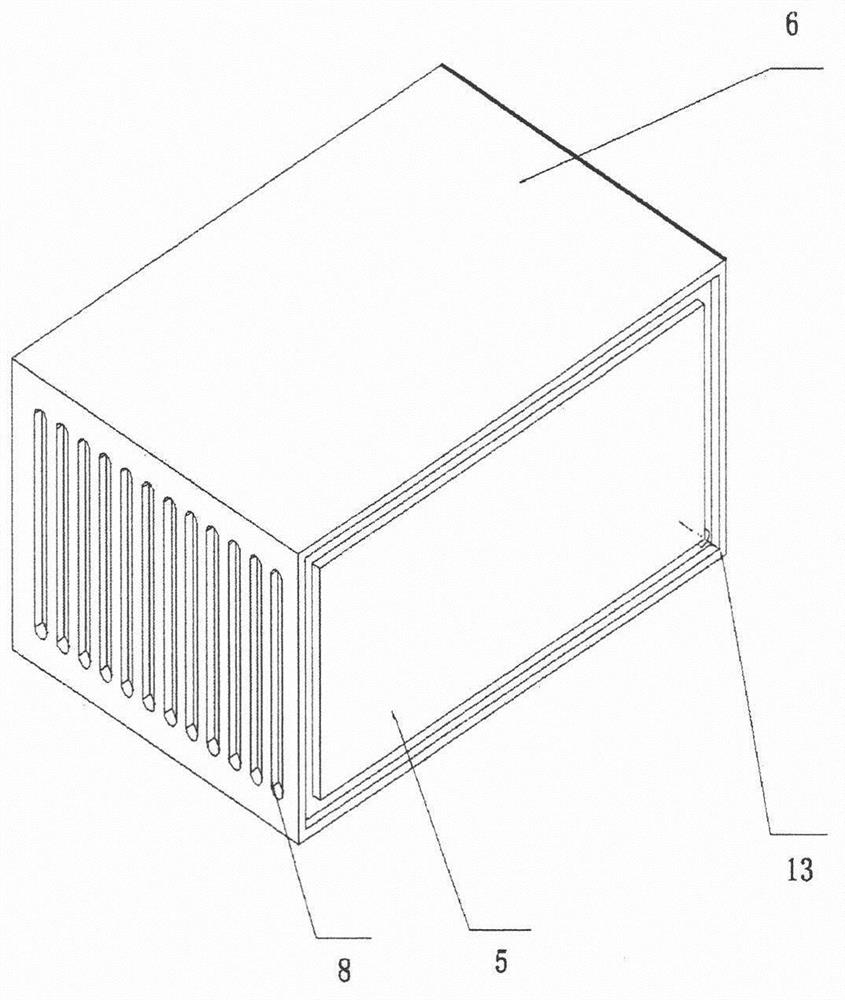

Super sterilization and purification device based on monopole rare earth material

PendingCN112325434ARelaxSame hot and cold resistanceTelevision system detailsMechanical apparatusHigh concentrationOxygen ions

The invention relates to a sterilization, ventilation and purification technology special for elevators, in particular to a super sterilization and purification device based on a monopole rare earth material. A sterilization technology that a special electric field generates a high temperature of 10,000 DEG C within 70 ns is adopted, temperature rise of equipment is only 5 DEG C, and droplet pollution in public places is solved. Meanwhile, a monopole rare earth emission technology of an ion cloud is designed for haze coating removing and positioning, fixed-point and regular cleaning is conducted in an elevator car within the range of 70 cm, consumable-free air purification and peculiar smell treatment are achieved, and the electric field power only needs to be about 6 watts; and through natural plant resin (sandalwood), air is fragrant, and an aromatic and beautiful artistic conception is provided. The high-concentration negative oxygen ion cloud is emitted through a rare earth material electrode, and 7 million negative oxygen ions are emitted per cubic centimeter. The equipment is also provided with a new light source (the illuminance is larger than 100 lm and the color temperature is 3,800-4,200 k) which is most suitable for the illuminance and the color temperature of the elevator. The sterilization and purification device has a huge application market and can be applied toclosed indoor space and mobile space (airplanes, steamships, automobiles, elevators and the like).

Owner:上海达奥斯电梯装潢有限公司

Air conditioner and control method

ActiveCN111912076BImprove work efficiencyIncrease the concentration of negative oxygen ionsMechanical apparatusSpace heating and ventilation safety systemsEngineeringMechanics

The invention discloses an air conditioner and a control method. The air conditioner comprises a refrigerant circulation loop, a compressor, a refrigerant circulation loop, a compressor, an indoor heat exchanger, an indoor fan, a negative ion module, an inlet air temperature sensor, an inlet air humidity sensor, air outlet temperature sensor and controller. The controller is configured to receive the inlet air temperature collected by the inlet air temperature sensor, the inlet air humidity collected by the inlet air humidity sensor, and the outlet air temperature collected by the outlet air temperature sensor when the indoor heat exchanger works as an evaporator. the outlet air temperature; determine the outlet air humidity of the indoor fan according to the inlet air temperature, the inlet air humidity and the outlet air temperature; control the outlet air temperature according to the outlet air humidity so that the The humidity of the air outlet is within the preset humidity range, so that the negative ion module can achieve the best working efficiency and quickly increase the concentration of negative oxygen ions in the indoor air.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

A kind of environment-friendly non-metal mute board and its manufacturing method

ActiveCN111333370BExtended service lifeAchieve fire resistanceFlat articlesOxygen ionsEnvironmental engineering

Owner:肖春秀

Preparation method of photocatalyst functional road material

ActiveCN104098291BImprove adsorption capacitySolve the problem of decomposing organic substratesCrushed stoneMicroparticle

The invention discloses a photocatalyst functional road material preparation method. The method comprises the following steps: 1, using broken granite with the average particle size of 3.5mm and asphalt as raw materials, mixing, heating, and making asphalt concrete permeable material sample blocks with the length of 100mm, the width of 50mm, the thickness of 5mm and the void fraction of 30% according to permeable concrete road construction requirements; using alumina cement and silica sand powder as aggregates and nanometer recombinant titanium dioxide microparticles obtained after 1500DEG C high temperature sintering as a photocatalyst, adding a water reducer and an inorganic resin emulsion, mixing with a weakly acidic solution (with the pH value of 4-6), and carrying out high frequency oscillation to prepare a photocatalyst suspension; and 3, spraying the asphalt concrete permeable material sample blocks with the prepared photocatalyst suspension, and instantly blowing the sprayed surface by a 100% carbonic acid high pressure gas to realize the normal temperature rapid drying hardening of the surface.

Owner:BEIJING JIANYUAN TIANDI ENVIRONMENTAL PROTECTION TECH

A varnish for releasing negative ions

The invention discloses a varnish for releasing negative ions and a preparation method thereof. The varnish for releasing negative ions is mainly composed of negative ion powder mixed with LED varnish, and the negative ion powder is 35-45 parts , 95-105 parts of LED varnish; the preparation method includes the following steps: S1: prepare anion powder and LED varnish; S2: heat the LED varnish prepared in step S1 in a water bath; S3: heat the LED varnish produced in step S1; The prepared negative ion powder is added to the LED varnish in S2 and stirred, and the negative ion powder is fully mixed with the LED varnish to obtain a varnish with negative ion powder. The varnish coated on the surface of the object can radiate air The air is ionized to release negative oxygen ions, remove the formaldehyde in the room, purify the indoor air, reduce the content of formaldehyde in the air, and at the same time provide negative oxygen ions for the room to create a healthy environment for people.

Owner:成都韩尚艺术贴花有限公司

Preparation method of gloss oil for releasing negative ions

The invention discloses a preparation method of gloss oil for releasing negative ions. The gloss oil is mainly prepared by mixing 35-45 parts of negative ion powder and 95-105 parts of LED gloss oil.The preparation method comprises the following steps of S1, preparing the negative ion powder and the LED gloss oil, S2, heating the LED gloss oil prepared in the step S1 in an oil-water bath, and then carrying out heat preservation, and S3, adding the negative ion powder prepared in S1 into the LED gloss oil prepared in S2 to be stirred, enab,ing the negative ion powder and the LED gloss oil to be fully mixed, and thus, preparing the gloss oil with the negative ion powder. The surface of an object is coated with the gloss oil, air can be radiated, air is ionized to release negative oxygen ions, indoor formaldehyde is removed, indoor air is purified, and the content offormaldehyde in the air is reduced, and meanwhile, negative oxygen ions can be provided for the interior of a room, and a healthy environment is created for people.

Owner:CHENGDU HANSHANG ART DECAL CO LTD

Construction method of health preservation system for phyllostachys pubescens forest

ActiveCN109673406AIncrease the concentration of negative oxygen ionsIncrease biodiversityPlant cultivationCultivating equipmentsHerbPhyllostachys

The invention discloses a construction method of a health preservation system for a phyllostachys pubescens forest. The construction method comprises the following steps: selecting a phyllostachys pubescens forest with a preset area; constructing at least one health preservation footpath around the phyllostachys pubescens forest, wherein the phyllostachys pubescens forest is capable of generatingnegative oxygen ions, the gradient of the health preservation footpath is less than 8%, and the width is more than 1.2m; planting arbors in the phyllostachys pubescens forest in a mixed manner, and planting shade-enduring shrubs and / or shade-enduring and officinal herbs in the phyllostachys pubescens forest along the terrain, wherein the planting area of the arbors is less than 25% of the total area of the phyllostachys pubescens forest, and the total canopy density of the phyllostachys pubescens forest in which the arbors are planted in a mixed manner is 0.6-0.9; and constructing waterscapes,buildings and a plurality of open spaces in the phyllostachys pubescens forest, wherein the area of the waterscapes is 20%-30% of the total area of the phyllostachys pubescens forest, and the area ofthe buildings is less than 0.5% of the total area of the phyllostachys pubescens forest.

Owner:SICHUAN AGRI UNIV

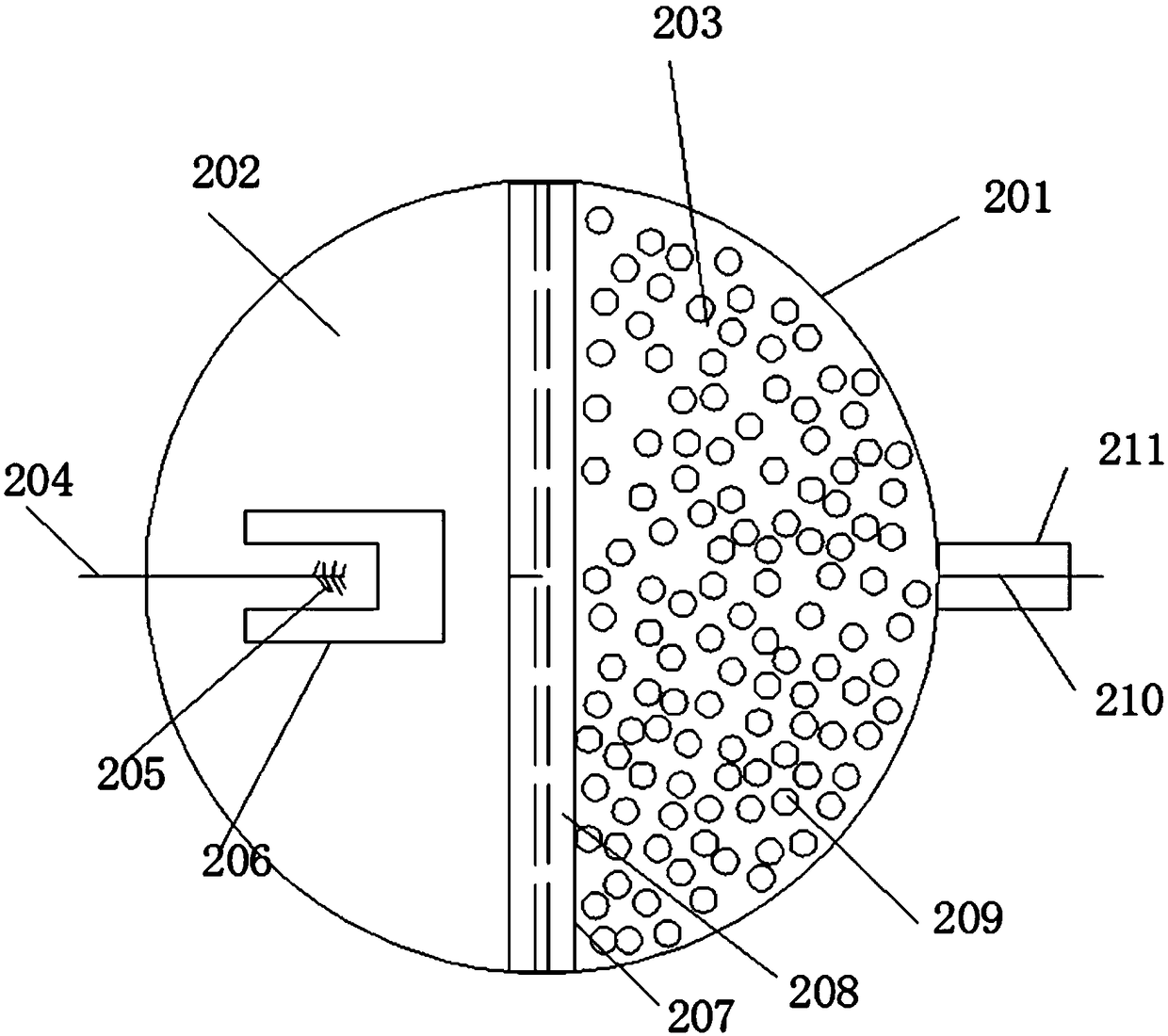

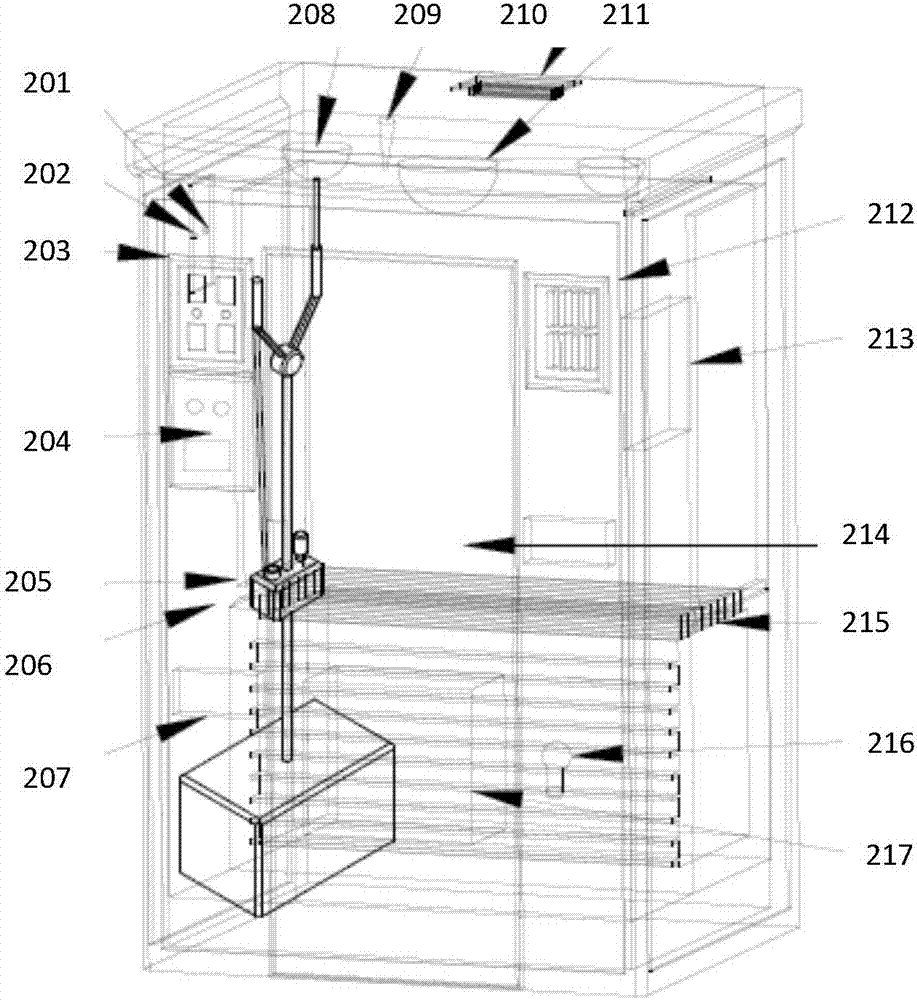

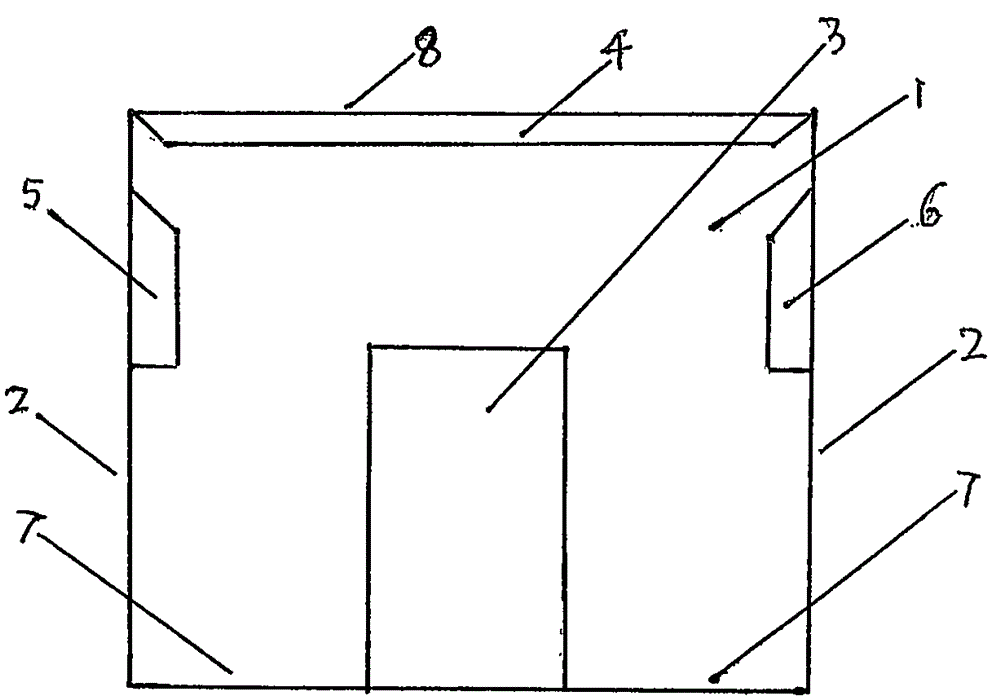

High-concentration high-stability negative-oxygen-ion therapeutic chamber

InactiveCN106693180ASatisfied with the treatment effectIncrease the electric field strengthBreathing protectionElectrotherapyFiberHigh concentration

The invention discloses a high-concentration high-stability negative-oxygen-ion therapeutic chamber. In the therapeutic chamber, a negative-oxygen-ion generator is mounted in the top of a chamber body, an ion releaser is prepared from a carbon fiber material whose area is the same with that of the chamber top, the plate is full of carbon fibers; and a chamber bottom made of a conductive material is grounded reliably; and four walls of the therapeutic chamber are made of an insulating material, and automatic humidity and temperature controllers are mounted in the chamber.

Owner:崔贵福

A kind of preparation method of negative ion emitting needle

ActiveCN108342615BImprove conductivityA lot of negative ions are releasedElectrical apparatusMetallic material coating processesNiobiumOxygen

The invention discloses a preparation method for a negative ion emission needle. The method adopts the following steps that step 1, an ingot blank is prepared, wherein the chemical components of the ingot blank are niobium, titanium and graphene, the composite of the niobium, the titanium and the graphene is added into an electron beam melting furnace for smelting, after full and uniform stirringis carried out, casting is carried out to form the ingot blank, and the temperature is cooled to the room temperature; step 2, forging and heat treatment are carried out, wherein the ingot blank is cut into alloy bars, rotary forging, hot pressing, cold pressing are sequentially carried out to prepare an alloy plate with the thickness of 0.1 mm, and the alloy plate undergoes annealing treatment, and then is cooled to the room temperature; step 3, machining, wherein the alloy plate is divided into a plurality of alloy rods, and the alloy rods are machined into the emission needles. and step 4,surface treatment is carried out, wherein gold plating is carried out on the surfaces of the emission needles, and a gold plating layer is formed on the surface of each emission needle. The emission needle is excellent in conductivity, large in negative ion release amount and long in distance, the generated oxygen negative ion concentration is high, and in addition, the gold plating layer on the surface of the emission needle effectively reduces the loss of the emission needle, and prolongs the service life of the emission needle.

Owner:Qingdao Kejian Kekang Anion Technology Co Ltd

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com