Environment-friendly water-resistant interior wall putty

A technology for interior wall putty and interior wall putty powder, which is applied in the field of building decoration materials, can solve the problems of user's money waste, chalking, wall peeling, etc., and achieves the effects of good grinding performance, good water retention and suitable viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

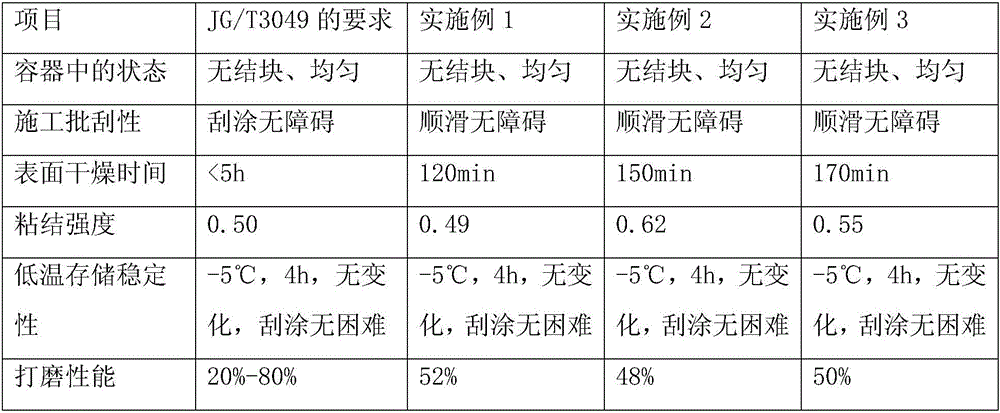

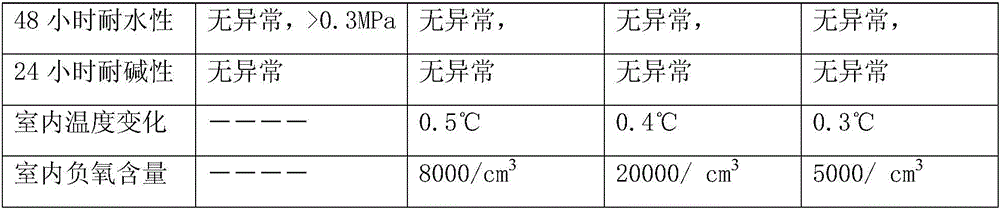

Embodiment 1

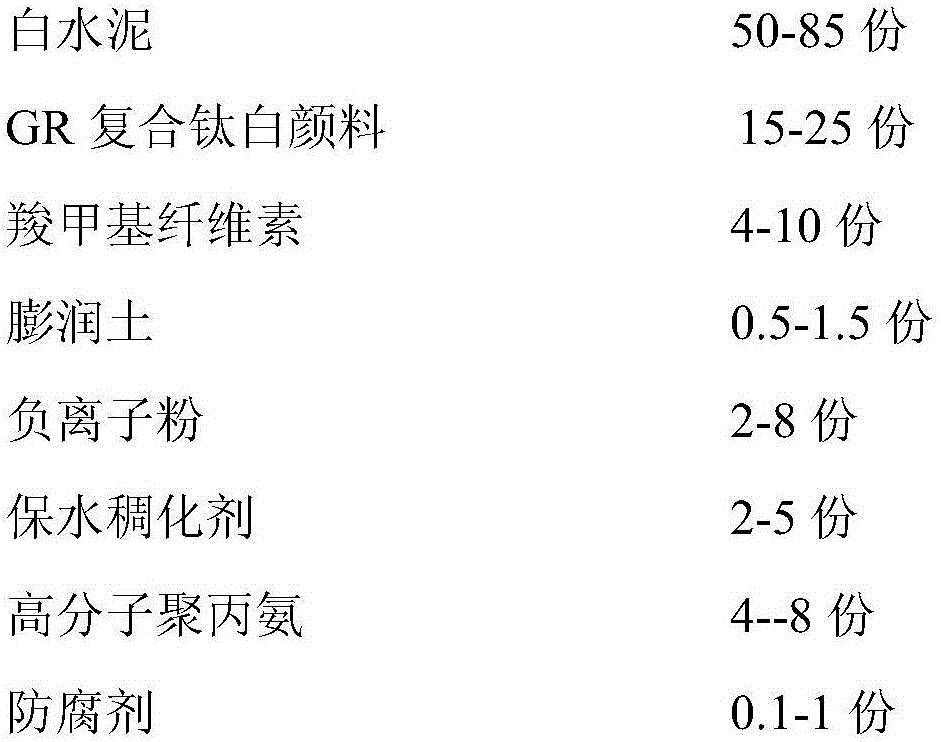

[0019] An environment-friendly and water-resistant interior wall putty, comprising the following components in parts by weight:

[0020] 50 parts of white cement, 25 parts of GR composite titanium dioxide pigment, 8 parts of carboxymethyl cellulose, 0.8 parts of sodium bentonite, 4 parts of negative ion powder, 4 parts of water-retaining thickener, 8 parts of high molecular polypropylamine, isothiazolinone 0.2 parts of similar compounds. The water-retaining thickener comprises 5% modified cellulose ether, 40% kaolin, 30% montmorillonite, 25% bentonite and 1% tartaric acid.

[0021] Add 50 parts of water into the mixing tank, then add 80 parts of putty powder, and stir with an electric mixer at a speed of 1000r / min for 30 minutes to fully stir evenly, let it stand for 10-15 minutes and stir again for 3-5 minutes, according to the construction According to the construction preferences of the personnel, the above operation can be repeated by adding water or increasing the amount...

Embodiment 2

[0023] An environment-friendly and water-resistant interior wall putty, comprising the following components in parts by weight:

[0024] 60 parts of white cement, 20 parts of GR composite titanium dioxide pigment, 4 parts of carboxymethyl cellulose, 0.6 parts of sodium bentonite, 8 parts of negative ion powder, 3 parts of water-retaining thickener, 4 parts of polymer polypropylamine, isothiazolinone 0.4 parts of similar compounds. The water-retaining thickener comprises 5% modified cellulose ether, 40% kaolin, 30% montmorillonite, 25% bentonite and 1% tartaric acid.

[0025] Add 60 parts of water into the mixing tank, then add 90 parts of putty powder, and stir with an electric mixer at a speed of 1000r / min for 30 minutes to fully stir evenly, let stand for 10-15 minutes and stir again for 3-5 minutes, according to the construction According to the construction preferences of the personnel, the above operation can be repeated by adding water or increasing the amount of putty ...

Embodiment 3

[0027] An environment-friendly and water-resistant interior wall putty, comprising the following components in parts by weight:

[0028] 72 parts of white cement, 15 parts of GR composite titanium dioxide pigment, 4 parts of carboxymethyl cellulose, 0.5 parts of sodium bentonite, 2 parts of negative ion powder, 2 parts of water-retaining thickener, 4 parts of polymer polypropylamine, isothiazolinone 0.5 parts of similar compounds. The water-retaining thickener comprises 5% modified cellulose ether, 40% kaolin, 30% montmorillonite, 25% bentonite and 1% tartaric acid.

[0029] Add 80 parts of water into the mixing tank, then add 100 parts of putty powder, stir with an electric mixer at a speed of 1000r / min for 30 minutes, make it fully stirred evenly, let it stand for 10-15 minutes and stir again for 3-5 minutes, according to the construction According to the construction preferences of the personnel, the above operation can be repeated by adding water or increasing the amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com