Method for improving antioxidant efficiency of antioxidants for polymer materials

A technology of polymer materials and antioxidants, which is applied in the field of thermo-oxidative stability of polymer materials, can solve problems such as lack of anti-oxidation effect and accelerated polymer aging, so as to expand the processing temperature window, reduce degradation and aging, Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Antioxidants AO and TrG are added to isotactic PP to improve the thermal oxygen stability of PP. The specific raw materials and their weight ratios are shown in Table 1.

[0050] The specific preparation method is as follows:

[0051] The first step, at first prepare raw materials by above-mentioned components;

[0052] In the second step, first place isotactic PP and thermally reduced graphene (TrG) in a 60°C oven for 12 hours;

[0053] Then, the isotactic PP, TrG and AO obtained in the second step were put into the torque rheometer and mixed for 10 minutes, and the processing temperature was 180°C, and the compound was taken out from the torque rheometer and shredded.

[0054] The obtained PP / AO / TrG composite material was pressed into a 0.5mm thick sheet by compression molding to test the barrier properties of the material. The molding temperature was 190°C and the pressure was 10MPa.

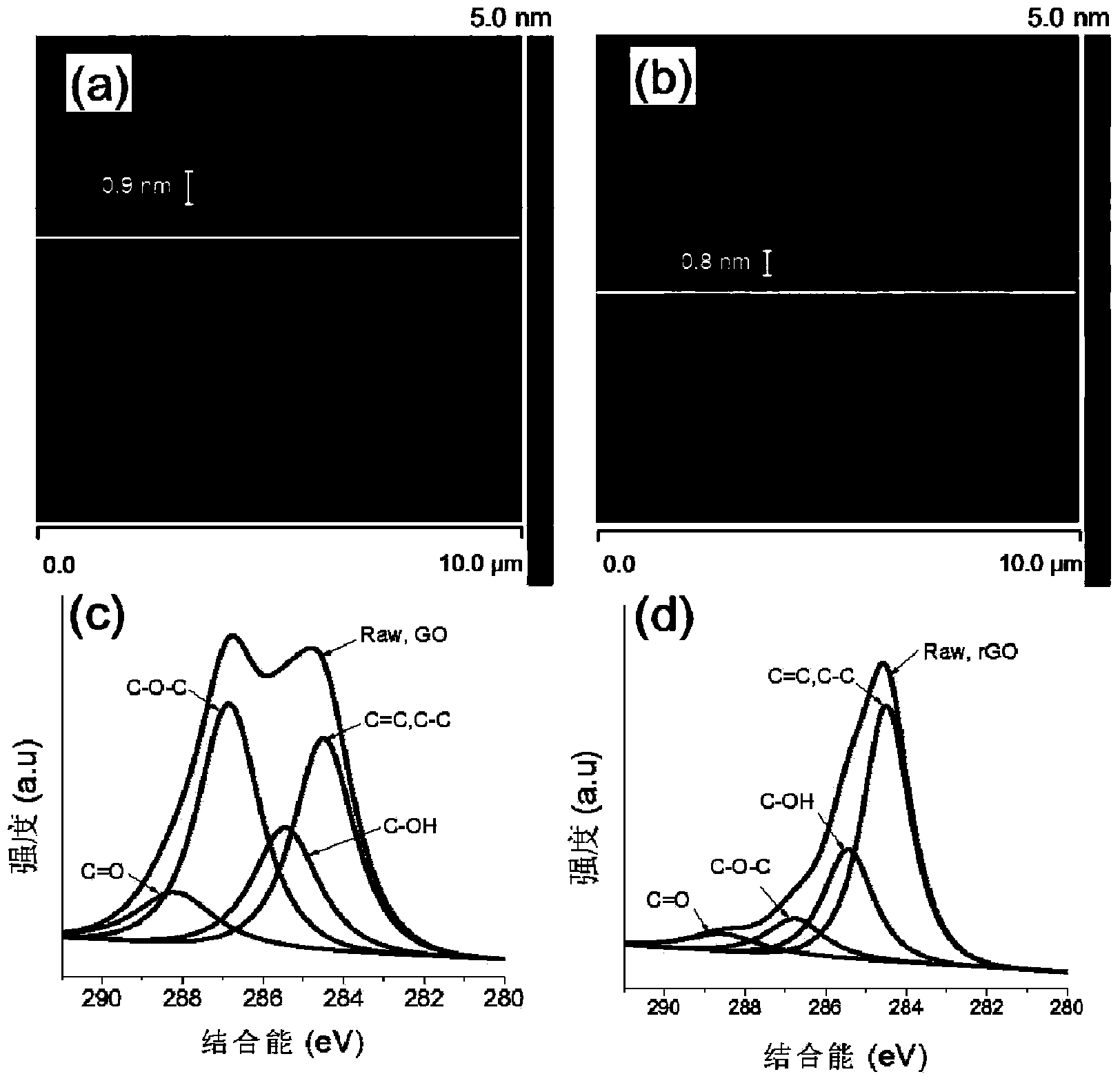

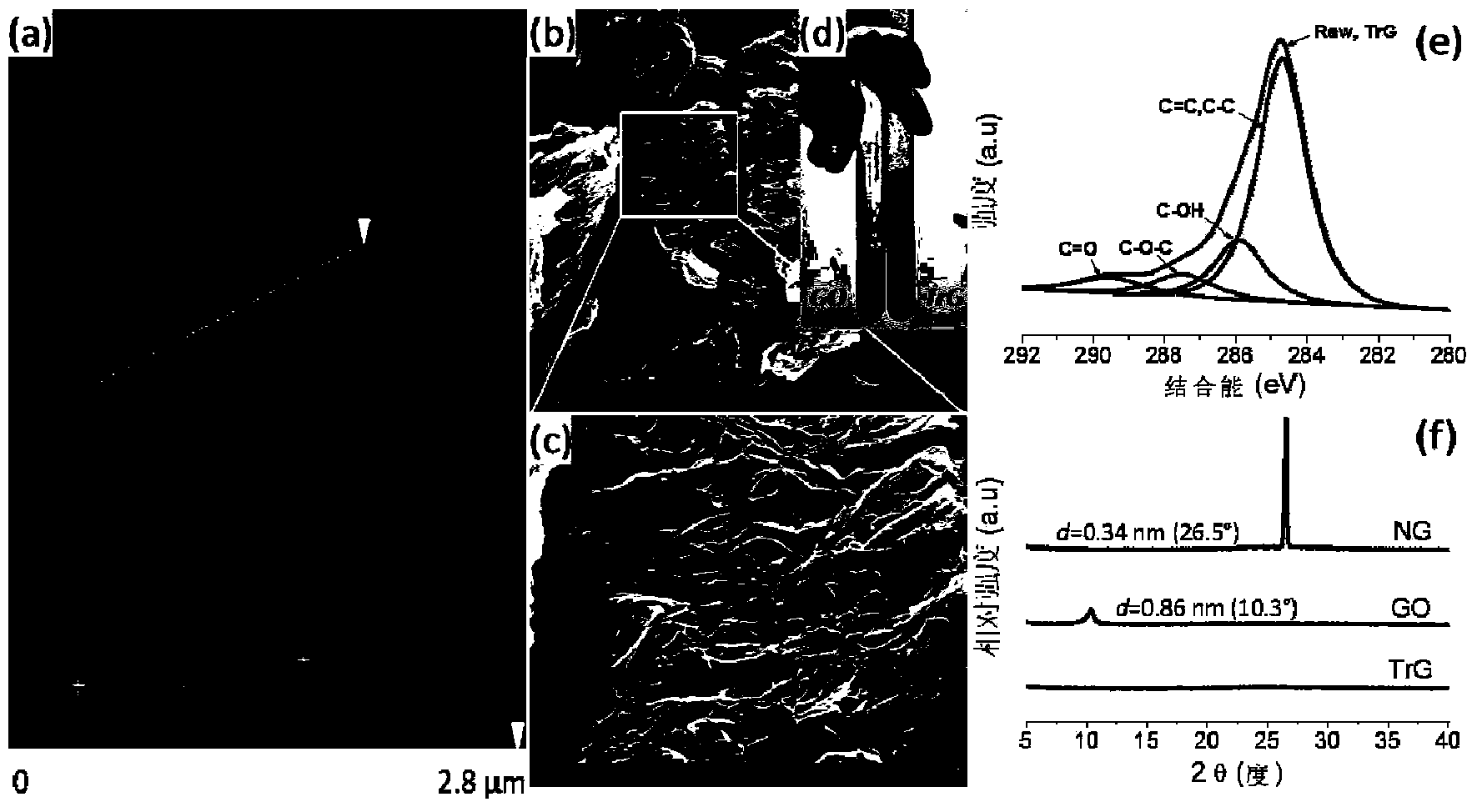

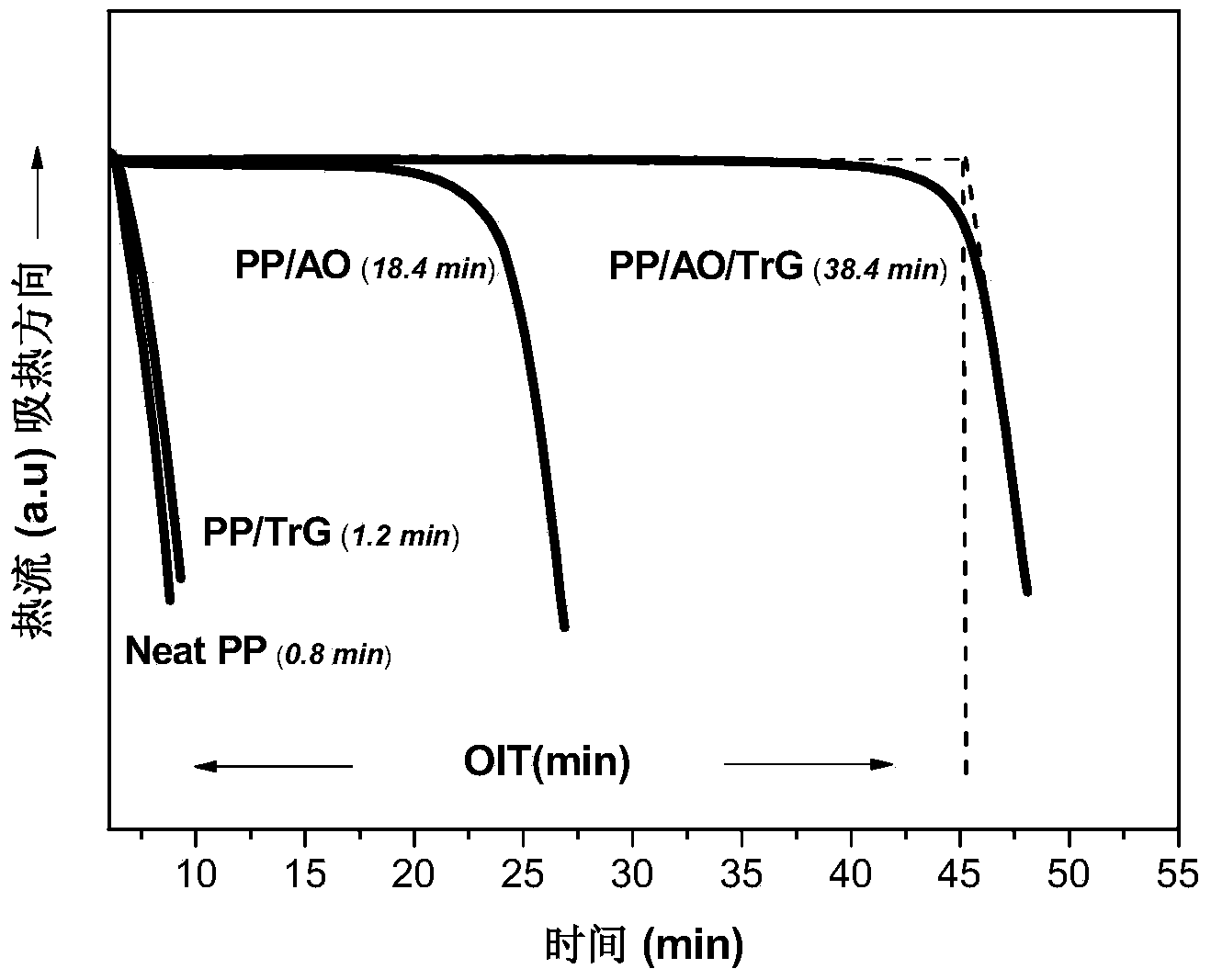

[0055] image 3 DSC degradation curves for pure PP, PP / TrG, PP / AO and PP / AO / TrG...

Embodiment 2-10

[0063] The raw material of embodiment 2-10 and its weight ratio are as shown in table 1, and its preparation method is the same as embodiment 1, and experimental result all shows: after adding antioxidant and graphene simultaneously, gained polymer / antioxidant / graphene The composite material is higher than the Ti of the polymer / antioxidant and polymer / graphene system (under the air atmosphere, the thermal decomposition temperature of the polymer / antioxidant / graphene composite is higher than that of the polymer / graphene composite). The decomposition temperature is 20°C higher, and the thermal decomposition temperature of the polymer / antioxidant / graphene composite is nearly 26°C higher than that of the polymer / antioxidant composite); and the OIT is also significantly improved, higher than The sum of the OIT of adding antioxidant alone or adding graphene alone (the OIT of polymer / antioxidant / graphene composite is close to twice the sum of OIT adding antioxidant alone and adding gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com