A kind of mesoporous molecular sieve modified anti-rutting agent and preparation method thereof

A technology of mesoporous molecular sieve and anti-rutting agent, which is used in building components, building insulation materials, buildings, etc., can solve the problems of physical migration and volatilization of anti-aging agents, reducing low-temperature performance of asphalt concrete, and limited anti-aging performance, etc. Anti-aging performance, improving anti-rutting performance and low temperature performance, the effect of not easy to rut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

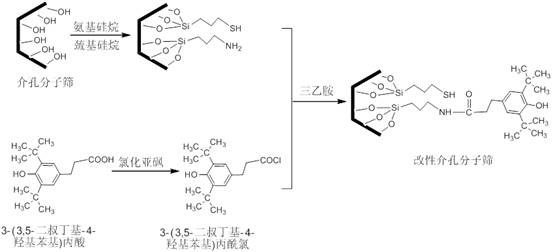

[0055] (1) Mix 1 part by weight of MCM-41 mesoporous molecular sieve (with a specific surface area of 1000 m 2 / g), 3-aminopropyltrimethoxysilane accounting for 15wt% of MCM-41 mesoporous molecular sieve and γ-mercaptopropyltrimethoxysilane accounting for 4wt% of MCM-41 mesoporous molecular sieve were added to 20 parts by weight of toluene . Keep the temperature at 110°C, keep stirring, heat and reflux for 3 hours, filter after cooling, wash with a large amount of ethanol, and dry at 100°C for 5 hours to obtain a mesoporous molecular sieve grafted with aminosilane and mercaptosilane.

[0056] (2) Under nitrogen protection, add 1 part by weight of 3-(3,5-di-tert-butyl-4-hydroxyphenyl)acrylic acid and 1.4 parts by weight of thionyl chloride into 30 parts by weight of chloroform, at 50°C Heating and reacting for 8 hours, and distilling under reduced pressure to obtain 3-(3,5-di-tert-butyl-4-hydroxyphenyl)acryloyl chloride.

[0057] (3) Add 1 part by weight of mesoporous molec...

Embodiment 2

[0060] (1) 1 part by weight of SBA-15 mesoporous molecular sieve (with a specific surface area of 1100 m 2 / g), 3-aminopropyltriethoxysilane accounting for 10wt% of SBA-15 mesoporous molecular sieve and γ-mercaptopropyltriethoxysilane accounting for 6wt% of SBA-15 mesoporous molecular sieve were added to 20 parts by weight in toluene. Keep the temperature at 110°C, keep stirring, heat and reflux for 3 hours, filter after cooling, wash with a large amount of ethanol, and dry at 100°C for 5 hours to obtain a mesoporous molecular sieve grafted with aminosilane and mercaptosilane.

[0061] (2) Under nitrogen protection, add 1 part by weight of 3,5-di-tert-butyl-4-hydroxybenzoic acid and 1.3 parts by weight of thionyl chloride into 25 parts by weight of chloroform, heat at 50°C for 8 hours, and reduce Pressure distillation to obtain 3,5-di-tert-butyl-4-hydroxybenzoyl chloride.

[0062] (3) Add 1 weight part of mesoporous molecular sieve grafted with aminosilane and mercaptosila...

Embodiment 3

[0065] (1) 1.5 parts by weight of SBA-16 mesoporous molecular sieve (with a specific surface area of 900 m 2 / g), γ-aminopropylmethyldiethoxysilane accounting for 5wt% of SBA-16 mesoporous molecular sieve and γ-mercaptopropylmethyldiethoxysilane accounting for 10wt% of SBA-16 mesoporous molecular sieve were added To 20 parts by weight of toluene. Keep the temperature at 110°C, keep stirring, heat and reflux for 3 hours, filter after cooling, wash with a large amount of ethanol, and dry at 100°C for 5 hours to obtain a mesoporous molecular sieve grafted with aminosilane and mercaptosilane.

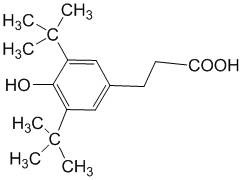

[0066] (2) Under nitrogen protection, 1 weight part of 3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid and 1.2 weight part of thionyl chloride were added to 25 weight parts of chloroform, 50 The reaction was heated at ℃ for 7h, and then distilled under reduced pressure to obtain 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl chloride.

[0067] (3) Add 1.5 parts by weight of mesopor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com