Grass meal based degradable agricultural mulch film and preparation method thereof

An agricultural mulch and grass powder-based technology, which is applied in the direction of plant protection covers, can solve the problems of degradation induction period and degradation rate, poor mechanical properties and water resistance, and inability to play a role in fertile fields, so as to achieve sufficient supply and good fertile fields The effect of saving food resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: In terms of 100 kilograms, the preparation method of the grass powder-based degradable agricultural mulch film provided in this embodiment is as follows:

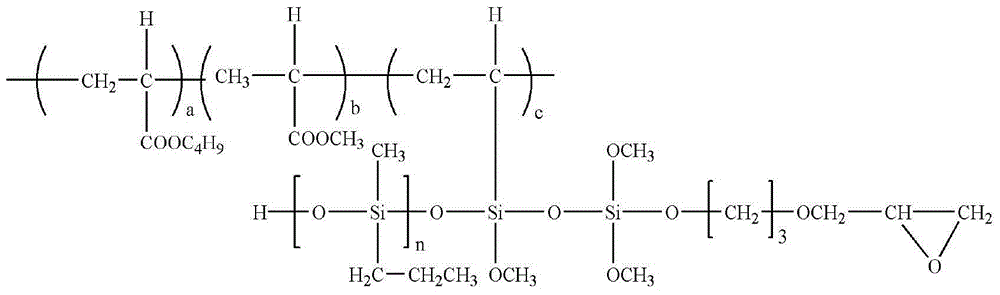

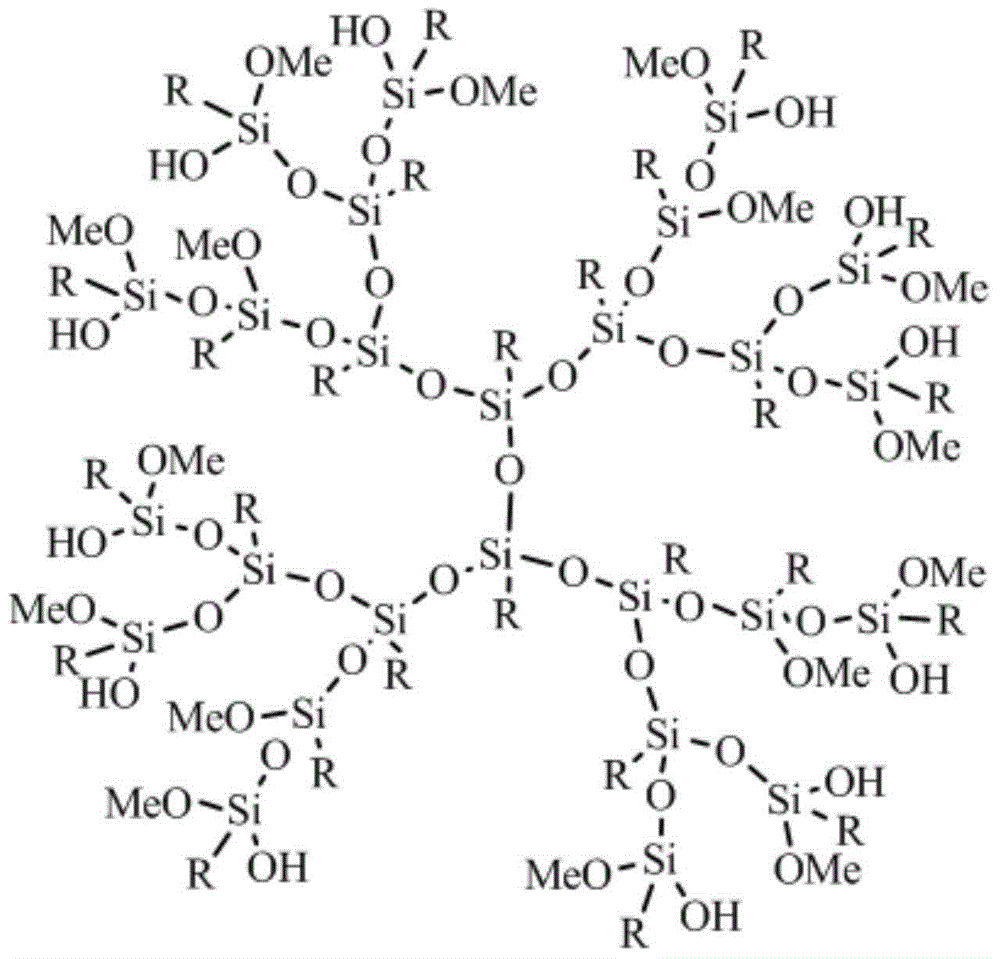

[0045] 1) In a 100-liter internal mixer, add 55 kg of hybrid pennisetum grass powder with a particle size of 500 mesh, 7.5 kg of Dow 3004 EAA resin, 5 kg of silicone acrylic resin containing epoxy groups, and silicone dendritic resin. 2.5 kg of resin monomer, 1 kg of epoxy soybean oil, 1 kg of polyethylene wax, 1 kg of titanium dioxide with a particle size of 1250 mesh, 1 kg of calcium carbonate with a particle size of 1500 mesh, banburying at 125°C for 2.5 hours, and then pouring into double The cone feeder is added to the single-screw granulator. The temperature of the three heating zones of the single-screw granulator is controlled at 125°C, 130°C, and 135°C respectively, and the temperature of the die head is controlled at 135°C. After cooling, enter the granulator to obtain 74 kg of modified grass ...

Embodiment 2

[0049] Embodiment 2: In terms of 100 kilograms, the preparation method of the grass powder-based degradable agricultural mulch film provided in this embodiment is as follows:

[0050] 1) Add 50 kg of Pennisetum grass powder with a particle size of 250 mesh, 7 kg of Dow 3004 EAA resin, 5 kg of epoxy-containing silicone acrylic resin, and silicone dendritic resin into a 100-liter mixer. 2 kg of monomer, 1 kg of epoxy soybean oil, 1 kg of polyethylene wax, 1 kg of titanium dioxide with a particle size of 1250 mesh, 1 kg of calcium carbonate with a particle size of 1500 mesh, banburying at 125°C for 2.5 hours, and then pouring into the double cone The feeder is added to the single-screw granulator, and the temperature of the three heating zones of the single-screw granulator is controlled at 125°C, 130°C, and 135°C respectively, and the temperature of the die head is controlled at 135°C. After entering the granulator, 68 kilograms of modified grass powder masterbatches were obtain...

Embodiment 3

[0053] Embodiment three: In terms of 100 kilograms, the preparation method of the grass powder-based degradable agricultural mulch film provided in this embodiment is as follows:

[0054] 1) Add 45 kg of 300-mesh wheatgrass powder, 15 kg of DuPont 2014 brand film grade EAA high-strength resin, 5 kg of epoxy-containing silicone acrylic resin, and silicone dendritic resin in a 100-liter internal mixer. 3 kg of monomer, 1 kg of epoxy soybean oil, 1 kg of polyethylene wax, 1 kg of 1250 mesh titanium dioxide, 1 kg of 1300 mesh calcium carbonate, banburying at 110~125°C for 1.5~2.5 hours, and then pouring into double cone The feeder is added to the single-screw granulator. The temperature of the three heating zones of the single-screw granulator is controlled at 120°C, 130°C, and 135°C respectively, and the temperature of the die head is controlled at 135°C. After entering the granulator, 72 kilograms of modified grass powder masterbatches were obtained.

[0055] 2) After mixing 22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com