A grass powder-based degradable agricultural mulch film and its preparation method

An agricultural mulch and grass powder-based technology, applied in plant protection covers, etc., can solve the problems of degradation induction period and slow degradation rate, poor mechanical properties and water resistance, and inability to play a role in fertile fields, so as to achieve sufficient supply and good fertile fields The effect of saving food resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: In terms of 100 kilograms, the preparation method of the grass powder-based degradable agricultural mulch film provided in this embodiment is as follows:

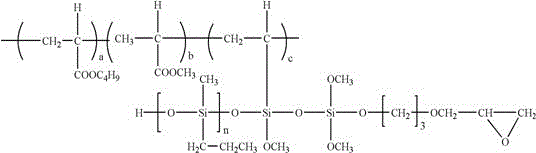

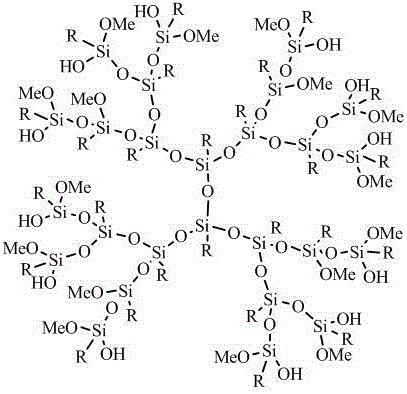

[0045] 1) Add 55 kg of hybrid pennisetum powder with a particle size of 500 mesh, 7.5 kg of Dow 3004 EAA resin, and epoxy-containing silicone into a 100-liter internal mixer 5 kg of acrylic resin, 2.5 kg of silicone dendritic resin monomer, 1 kg of epoxy soybean oil, 1 kg of polyethylene wax, 1 kg of titanium dioxide with a particle size of 1250 mesh, and 1 kg of calcium carbonate with a particle size of 1500 mesh, at 125°C Mixed for 2.5 hours, then poured into the double-cone feeder and added to the single-screw granulator. The temperature of the three heating zones of the single-screw granulator was controlled at 125°C, 130°C, and 135°C, and the temperature of the die head was controlled at 135°C. After exiting the die head, it enters the air cushion air cooling, and enters the granulator after cool...

Embodiment 2

[0049] Embodiment 2: In terms of 100 kilograms, the preparation method of the grass powder-based degradable agricultural mulch film provided in this embodiment is as follows:

[0050] 1) Add 50 kg of Pennisetum powder with a particle size of 250 mesh, 7 kg of Dow 3004 EAA resin, organic epoxy-containing organic compound into a 100-liter internal mixer 5 kg of silicone acrylic resin, 2 kg of silicone dendritic resin monomer, 1 kg of epoxy soybean oil, 1 kg of polyethylene wax, 1 kg of titanium dioxide with a particle size of 1250 mesh, 1 kg of calcium carbonate with a particle size of 1500 mesh, at 125 ° C Mix for 2.5 hours, then pour it into the double-cone feeder and add it to the single-screw granulator. The temperature of the three heating zones of the single-screw granulator is controlled at 125°C, 130°C, and 135°C respectively, and the temperature of the die head is controlled at 135°C. , enter the air cushion air cooling after exiting the die head, and enter the granul...

Embodiment 3

[0053] Embodiment three: In terms of 100 kilograms, the preparation method of the grass powder-based degradable agricultural mulch film provided in this embodiment is as follows:

[0054] 1) Add 45 kg of 300-mesh wheat straw powder, 15 kg of DuPont 2014 brand film-grade EAA high-strength resin, 5 kg of epoxy-containing silicone acrylic resin, and silicone dendritic resin into a 100-liter internal mixer. Body 3 kg, epoxidized soybean oil 1 kg, polyethylene wax 1 kg, 1250 mesh titanium dioxide 1 kg, 1300 mesh calcium carbonate 1 kg, banburying at 110~125℃ for 1.5~2.5 hours, then pour into double cone feeding The temperature of the three heating zones of the single-screw granulator is controlled at 120°C, 130°C, and 135°C respectively, and the temperature of the die head is controlled at 135°C. After exiting the die head, it enters the air cushion air cooling, and after cooling Enter the granulator to obtain 72 kg of modified grass powder masterbatch.

[0055] 2) Mix 22.5 kg of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com