New natural plant inorganic environment-friendly paint and preparation method thereof

A natural plant and environmentally friendly coating technology, applied in the direction of alkali metal silicate coatings, coatings, etc., can solve the problems of non-environmental protection and high cost of organic coatings, and achieve the effects of good temperature resistance, low cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

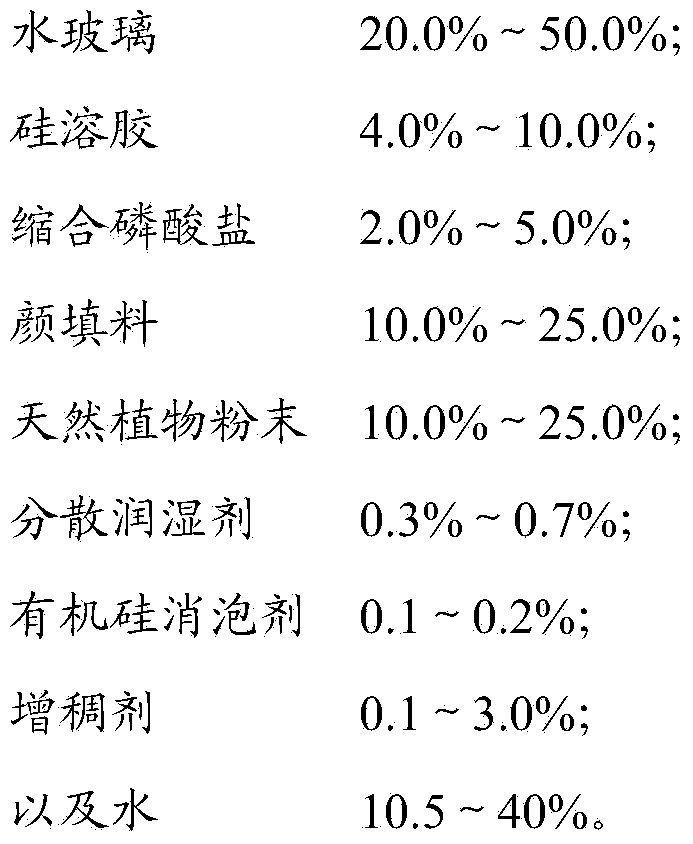

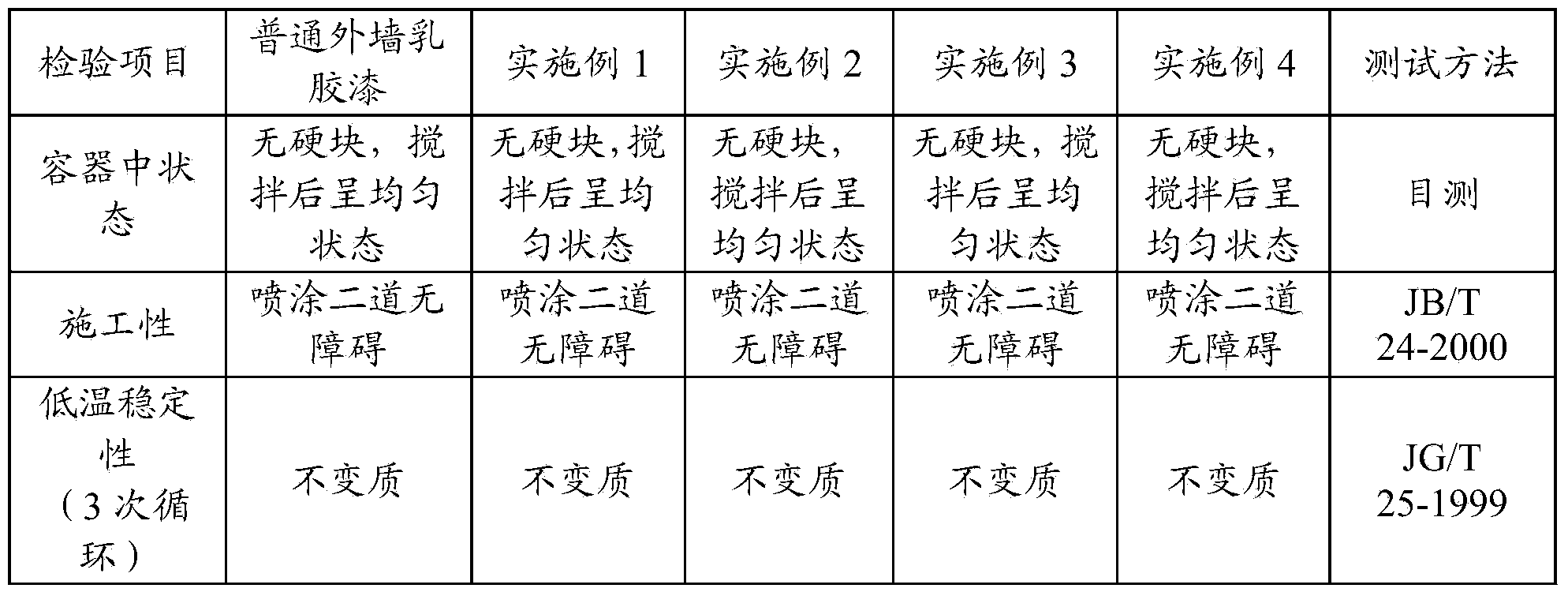

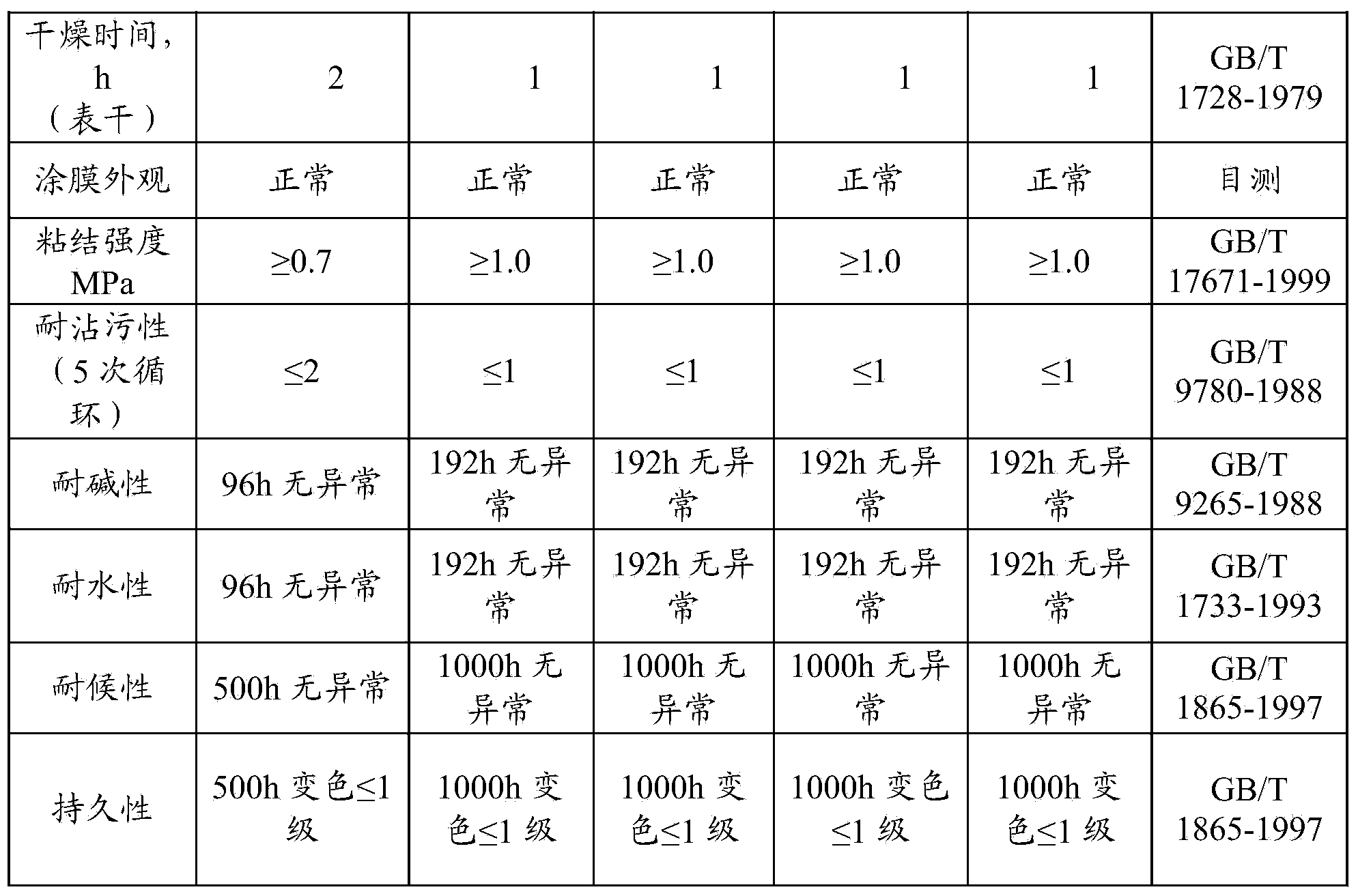

[0034] The raw material formula (wt%) of natural plant novel inorganic environment-friendly coating is shown in table 1 below.

[0035] The raw material formula (wt %) of the natural plant novel inorganic environmental protection coating of table 1 embodiment 1

[0036] water glass

20.0%

2.0%

Silica sol

4.0%

Pigments

21.0%

20.5%

wetting and dispersing agent

0.32%

0.15%

thickener

0.12%

water

31.91%

[0037] The preparation method of natural plant novel inorganic environment-friendly coating, it comprises the steps:

[0038] According to the above formula, the above-mentioned components account for the silicone defoamer of 0.1% of the above-mentioned component organosilicon defoamer quality, the above-mentioned component wetting and dispersing agent, the above-mentioned component pigments and fillers, the ab...

Embodiment 2

[0040] The raw material formulation (wt%) of the natural plant novel inorganic environmental protection coating is shown in Table 2 below.

[0041] The raw material formula (wt%) of the natural plant novel inorganic environmental protection coating of table 2 embodiment 2

[0042] water glass

38%

3.8%

Silica sol

5.4%

Pigments

20.2%

20.0%

wetting and dispersing agent

0.4%

Silicone defoamer

0.2%

thickener

0.15%

water

11.85%

[0043] The preparation method of natural plant novel inorganic environment-friendly coating, it comprises the steps:

[0044]According to the above formula, the above-mentioned components account for 0.2% of the organic silicon defoamer of the above-mentioned component organosilicon defoamer quality, the above-mentioned component wetting and dispersing agent, the above-mentioned component pigments and fi...

Embodiment 3

[0046] The raw material formulation (wt%) of the natural plant novel inorganic environmental protection coating is shown in Table 3 below.

[0047] The raw material formula (wt%) of the natural plant novel inorganic environmental protection coating of table 3 embodiment 3

[0048] water glass

30.0%

3.0%

Silica sol

6.2%

Pigments

15.4%

15.5%

wetting and dispersing agent

0.5%

Silicone defoamer

0.15%

thickener

0.13%

water

29.12%

[0049] The preparation method of natural plant novel inorganic environment-friendly coating, it comprises the steps:

[0050] According to the above formula, the above-mentioned components account for the silicone defoamer of 0.15% of the above-mentioned component organosilicon defoamer quality, the above-mentioned component wetting and dispersing agent, the above-mentioned component pigments and fill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com