Manufacture method of optical fiber probe

An optical fiber probe and etching solution technology, which is applied in scanning probe technology, scanning probe microscopy, instruments, etc., can solve the problems of improvement of conical light transmittance, reduction of resolution, and uneven surface roughness of the probe , to achieve the effect of smooth surface morphology, high controllability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The optical fiber probes obtained by the existing preparation methods are all linear tapered. However, the light transmittance of linear tapered probes is limited, and the nonlinear tapered structure (with a changing cone angle) can change the transmission characteristics of light and improve The light transmittance has broad application prospects. In the present invention, adjusting liquid is added in the etching process, and by changing the type and dripping speed of the adjusting liquid, the tapered shape of the optical fiber probe is adjusted to prepare non-linear tapered probes of different shapes, which is conducive to further in-depth research on the effect of the tapered change on the probe. The influence of needle light rate.

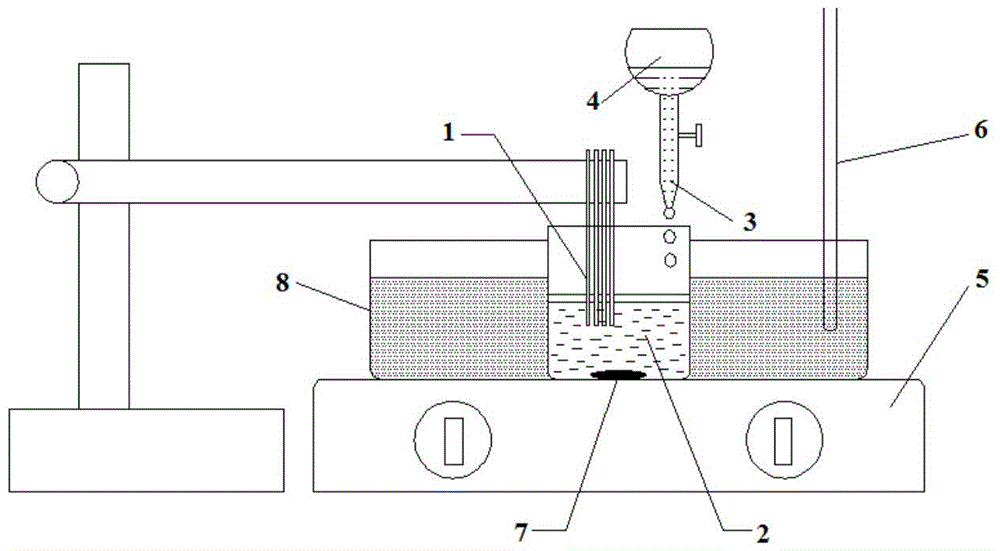

[0023] The preparation method of the optical fiber probe of the embodiment of the present invention comprises the following steps:

[0024] (1) Mix HF solution and NH 4 The F solution is mixed to obtain an etching solution, and an orga...

Embodiment 1

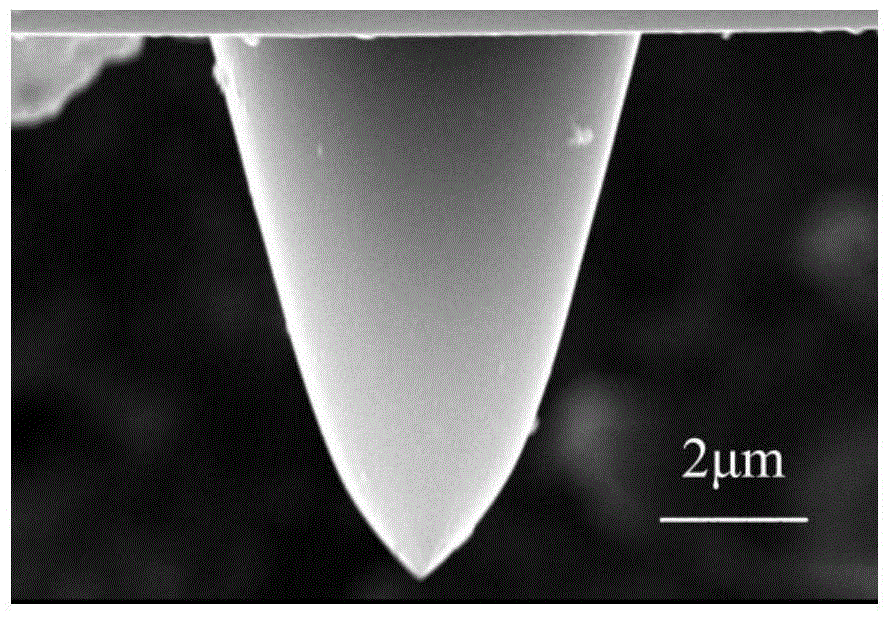

[0033] 10ml of 50% HF solution and 23ml of 22% NH 4 F solution was mixed to form an etching solution, and a layer of isooctane with a thickness of 3 cm was covered on the etching solution; the magnetic stirrer 5 was turned on, and the temperature of the etching solution was controlled at 28° C. with a water bath; the optical fiber was inserted into the etching solution , for 60min of static etching; the mass fraction of 40% NH 4 F solution is injected into the flow controller 4 as the adjustment liquid, put the stirrer 7 into the etching solution and start stirring, open the valve of the flow controller to let the adjustment liquid drop into the etching solution, the dropping speed is 0.3ml / min, drop into The process lasts for 15 minutes; adjust the dropping speed to 1.5ml / min, and the dropping process lasts for 15 minutes; the stirring bar stops stirring, maintains the current concentration, and performs static etching for 10 minutes.

[0034] The prepared fiber optic probes...

Embodiment 2

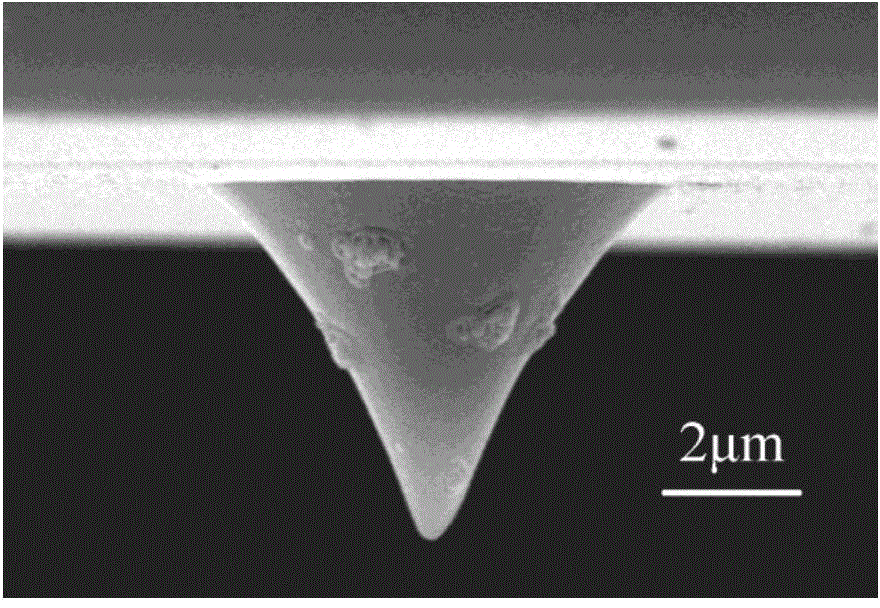

[0036] 20ml mass fraction of 22% HF solution and 19ml mass fraction of 40% NH 4F solution was mixed to form an etching solution, and a layer of isooctane with a thickness of 3 cm was covered on the etching solution; the magnetic stirrer 5 was turned on, and the temperature of the etching solution was controlled at 30° C. with a water bath; the optical fiber was inserted into the etching solution , carry out static etching for 20 min; inject the HF solution with a mass fraction of 22% as the adjustment liquid into the flow controller 4, put the stirrer 7 into the etching solution and start stirring, open the valve of the flow controller to allow the adjustment liquid to drip into the In the etching solution, the dropping speed is 1ml / min, and the dropping process lasts for 15 minutes; adjust the dropping speed to 0.3ml / min, and the dropping process lasts for 5 minutes; the stirring bar stops stirring, maintains the current concentration, and performs static etching for 5 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com