Black agaric cultivation method

A cultivation method and technology of black fungus, applied in the cultivation field of edible fungus, can solve the problems of high pollution rate, poor quality, low yield, etc., and achieve the effect of high biological efficiency, stable yield and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

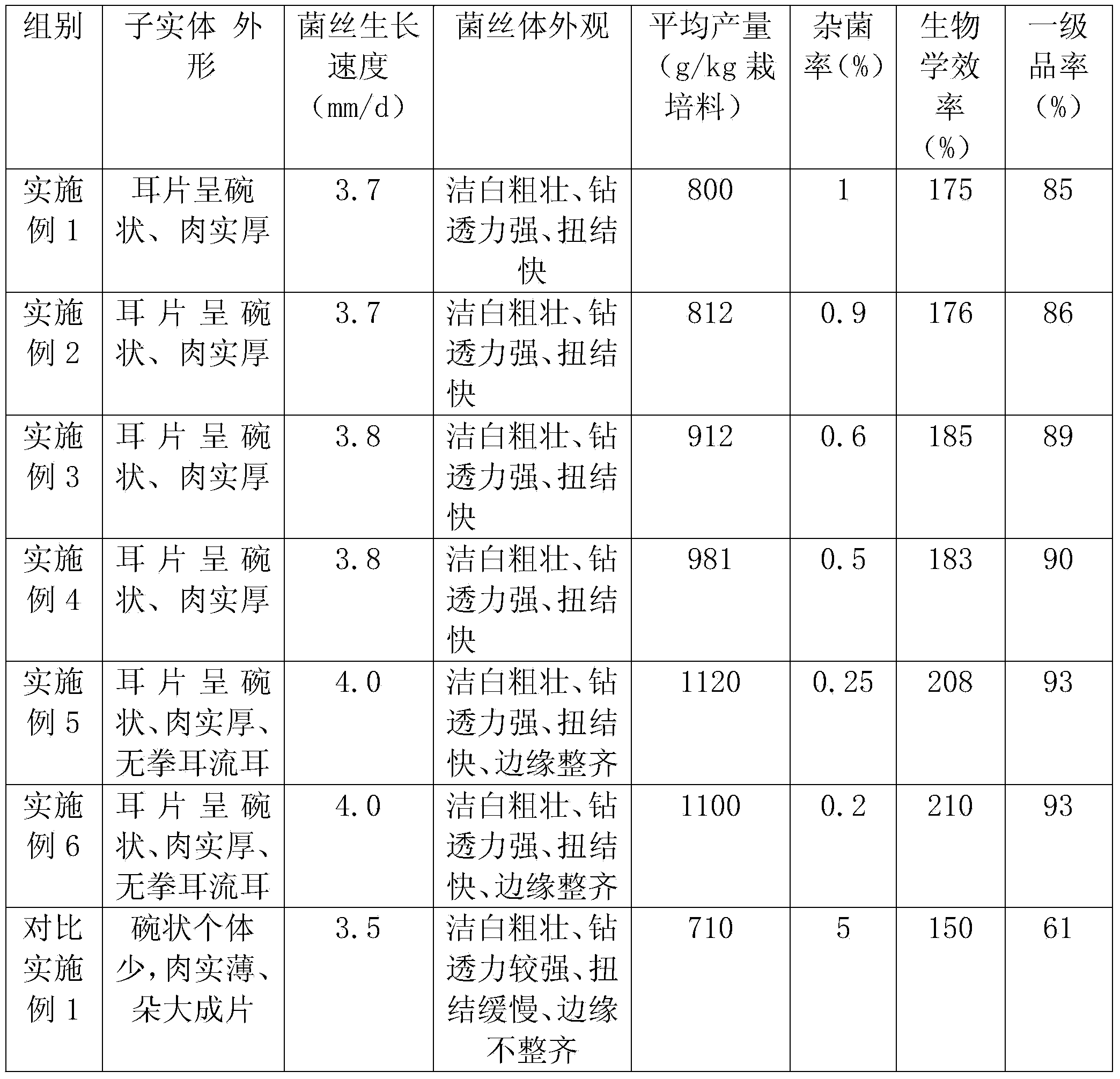

Examples

Embodiment 1

[0017] 1) Fully mix 40kg of mulberry wood chips, 25kg of peanut shells, 0.2kg of gypsum powder, 0.2kg of quicklime, 0.05kg of Magnolia bark powder, 0.01kg of Scutellaria chinensis powder, and 0.01kg of Scrophulariaceae powder, add water until the water content is 55%, and mix Evenly, it is the cultivation material;

[0018] 2) Pack the cultivation material into bags, each bag is filled with 2kg, which is the material bag;

[0019] 3) Keep the material bag at 95°C for 18 hours to sterilize and cool, inoculate both ends, and sterilize at 20°C, which is the bacteria bag;

[0020] 4) Use iron nails with a diameter of 6 mm to uniformly puncture the fungus bag with a hole depth of 1.5 cm, and destroy the ear under the conditions of 18°C and air humidity of 85%, which is the ear bag;

[0021] 5) Put the ear bags end to end and put them flat on the ear field, and manage them at 18°C and 90% air humidity. When the ear pieces are fully unfolded, the roots of the ears become thinner...

Embodiment 2

[0023] 1) Fully mix 75kg of mulberry wood chips, 30kg of peanut shells, 5kg of gypsum powder, 5kg of quicklime, 0.5kg of Magnolia officinalis powder, 0.1kg of Scutellaria baicalensis powder, and 0.05kg of Scrophulariaceae powder, add water until the water content is 65%, and mix evenly. is the cultivation material;

[0024] 2) Pack the cultivation material into bags, each bag is filled with 3kg, which is the material bag;

[0025] 3) Keep the material bag at 105°C for 22 hours to sterilize and cool, inoculate both ends, and sterilize at 26°C, which is the bacteria bag;

[0026] 4) Use iron nails with a diameter of 8 mm to uniformly puncture the fungus bag with a hole depth of 2 cm, and destroy the ear under the conditions of 24 ° C and 90% air humidity, which is the ear bag;

[0027] 5) Put the ear bags end to end and put them flat on the ear field, and manage the ear harvesting under the conditions of 24°C and 95% air humidity. When the ear pieces are fully unfolded, the ear...

Embodiment 3

[0029] 1) Fully mix 40kg of mulberry wood chips, 30kg of peanut shells, 0.2kg of gypsum powder, 5kg of quicklime, 0.05kg of Magnolia officinalis powder, 0.1kg of Scutellaria baicalensis powder, 0.01kg of Scrophulariaceae powder, and 0.5kg of garlic powder, and add water until the water content is 55%, mixed evenly, is the cultivation material;

[0030] 2) Pack the cultivation material into bags, each bag is filled with 3kg, which is the material bag;

[0031] 3) Keep the material bag at 95°C for 22 hours to sterilize and cool, inoculate both ends, and sterilize at 26°C, which is the bacteria bag;

[0032] 4) Use iron nails with a diameter of 6 mm to evenly puncture the fungus bag with a hole depth of 2 cm, and destroy the ear under the conditions of 18°C and 90% air humidity, which is the ear bag;

[0033] 5) Put the ear bags end to end and put them flat on the ear field, and manage the ear harvesting under the conditions of 18°C and 95% air humidity. When the ear pieces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com