Anti-fatigue microemulsion and preparation method thereof

A microemulsion, anti-fatigue technology, applied in emulsion delivery, antidote, pharmaceutical formulations, etc., can solve problems such as easy side effects, cardiac pressure, etc., to avoid first-pass effect of liver and intestine, maintain stable effect, and improve body surface absorption. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 80 parts of ginsenoside, 80 parts of gypenoside and 100 parts of gelatin, heat and mix at 80°C. Another 20 parts of polyethylene terephthalate particles were dissolved in 200 ml of dichloromethane, a certain volume and concentration of gelatin aqueous solution was added, and the mixture was continuously stirred.

[0025] The above two were mixed, stirred and dispersed for 30 minutes to obtain a W / O emulsion. Add 1600 ml of 8% gelatin aqueous solution to the W / O emulsion, stir and disperse for 30 minutes to make a W / O / W emulsion. The above emulsion was distilled at 40°C, distilled out the oil phase capsule wall solvent methylene chloride, filtered, washed, dried and shaped to obtain a microcapsule sample.

[0026] Finally, add dilute gelatin solution to the above-mentioned microcapsule sample, then add herbal essential oil, laurocapram, gum arabic and menthol in the prescribed amount, make a microcapsule emulsion under high-speed stirring, and divide it to obtain ...

Embodiment 2

[0028] Weigh 100 parts of ginsenoside, 100 parts of gypenoside and 150 parts of gelatin, heat and mix, and the heating temperature is 80°C. Another 40 parts of polyethylene terephthalate particles were dissolved in 400 parts of dichloromethane, a certain volume and concentration of gelatin aqueous solution was added, and the mixture was continuously stirred.

[0029] The above two were mixed, stirred and dispersed for 30 minutes to obtain a W / O emulsion. Add 100 parts of 15% gelatin aqueous solution to the W / O emulsion, stir and disperse for 30 minutes to make a W / O / W emulsion. The above emulsion was distilled at 40°C, distilled out the oil phase capsule wall solvent methylene chloride, filtered, washed, dried and shaped to obtain a microcapsule sample.

[0030] Finally, add dilute gelatin solution to the above-mentioned microcapsule sample, then add herbal essential oil, laurocapram, gum arabic and menthol in the prescribed amount, make a microcapsule emulsion under high-spe...

Embodiment 3

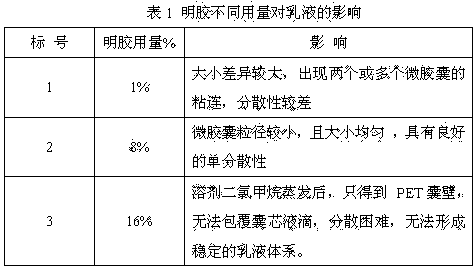

[0032] Investigate the impact of the different consumptions of emulsifier gelatin on the emulsion of the present invention, the results are as shown in table 1:

[0033]

[0034] Other preparation conditions are the same as in Example 1, and the results show that the average particle size of the microcapsules becomes smaller and the particle size distribution range narrows as the gelatin dosage increases while maintaining a certain capsule core / capsule wall ratio. When the amount of gelatin is 8%, the effect of the obtained microcapsules is better, which is conducive to the formation of a stable emulsion system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com