Circulating high-temperature flue gas flowing-state non-blocking tubular bagasse drying system

A high-temperature flue gas and drying system technology, which is applied in drying, dryers, and greenhouse gas reduction, can solve problems such as affecting boiler combustion, easy coking of the furnace, and large heat loss during combustion, so as to improve efficiency and social benefits , Promote economic development and increase furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

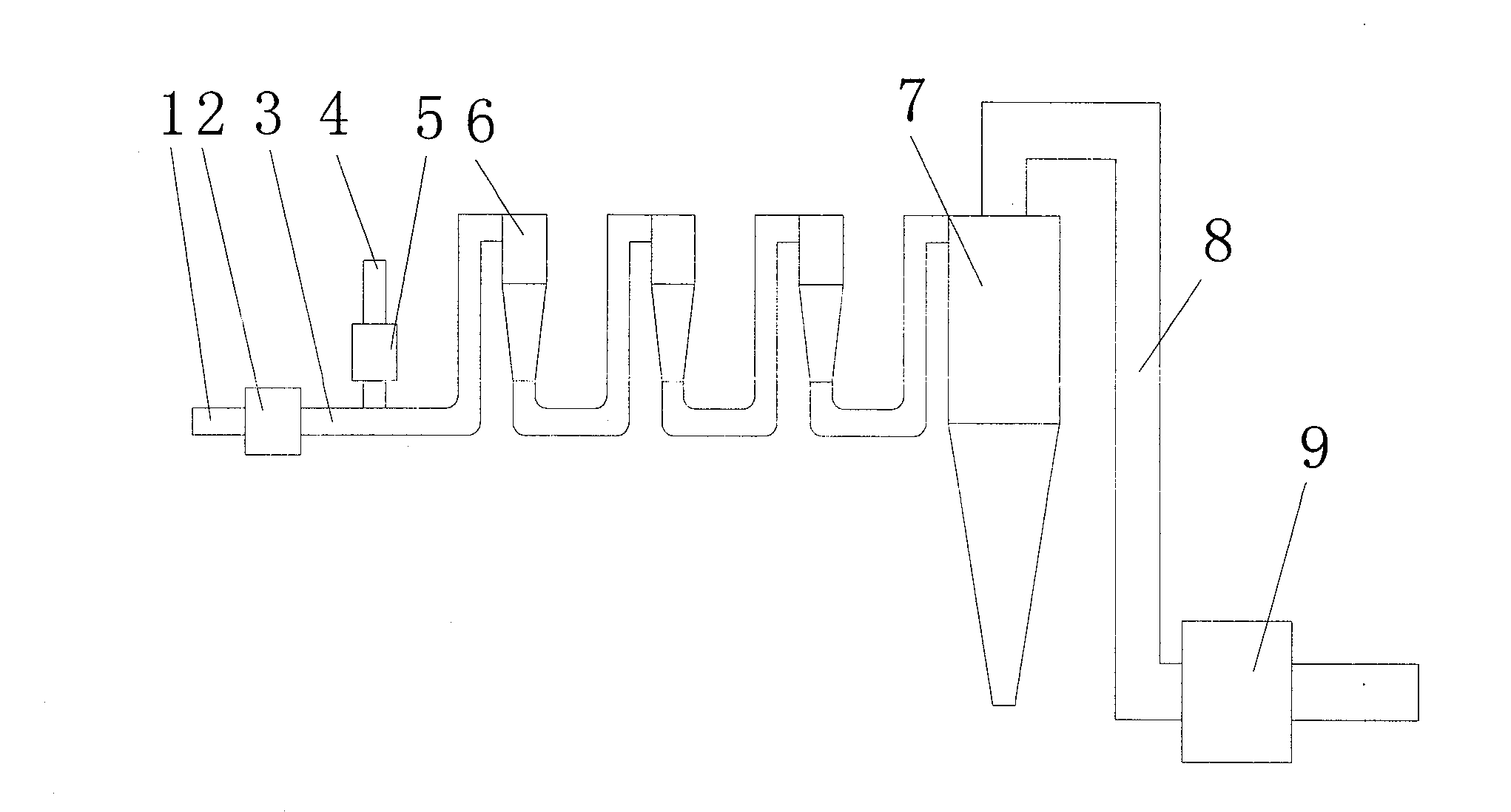

[0008] Referring to the accompanying drawings, a circulating high-temperature flue gas flow non-blocking tubular bagasse drying system according to the present invention is composed of a high-temperature flue gas pipe inlet 1, a high-pressure fan 2, a high-temperature flue gas pipe 3, and a bagasse inlet 4 , discharge valve 5, cyclone fire extinguisher 6, cyclone separator 7, smoke exhaust pipe 8 and circulating high-pressure fan 9. The inlet 1 of the high-temperature flue gas pipe is installed in front of the high-temperature economizer and the outlet pipe of the high-temperature flue gas pipe 3 connected with the high-pressure fan 2, the bagasse inlet 4 and the discharge valve 5 are installed in front of the cyclone fire extinguisher 6, and the smoke exhaust The smoke pipe 8 is installed in the center of the cyclone separator 7 and connected to the circulating high-pressure blower 9 . The high-temperature flue gas 1 used in this embodiment is the flue gas before the economiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com