Rock core preparation method

A production method and core technology, applied in the field of petroleum exploration, can solve problems such as unreliable results and failure to reach the nanometer level, and achieve reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

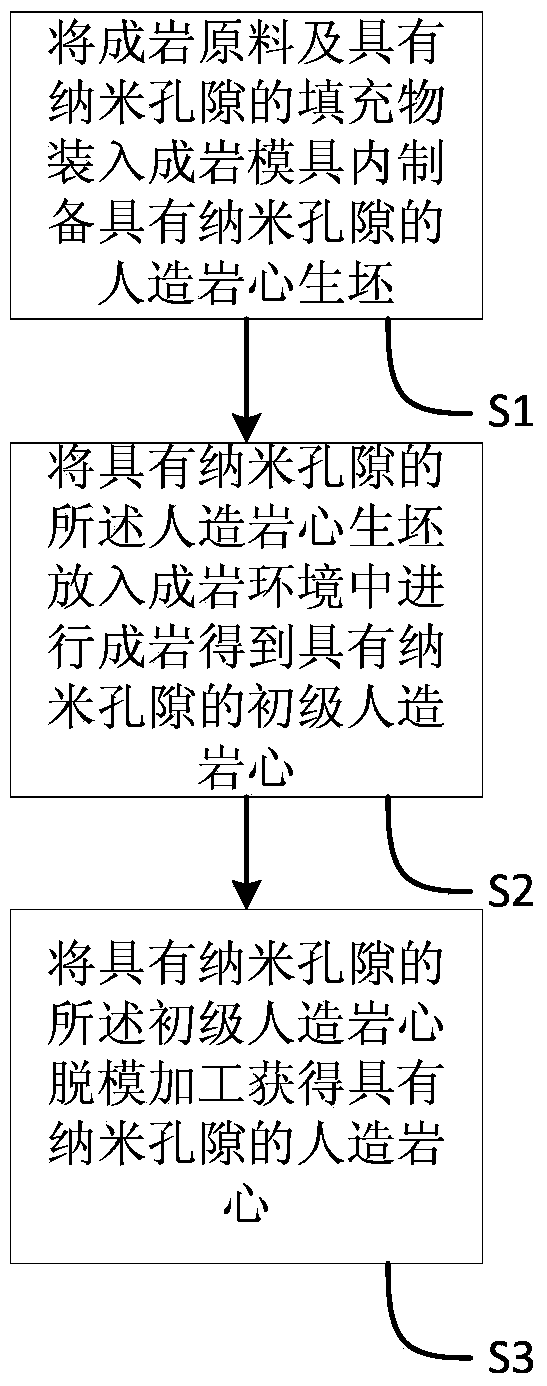

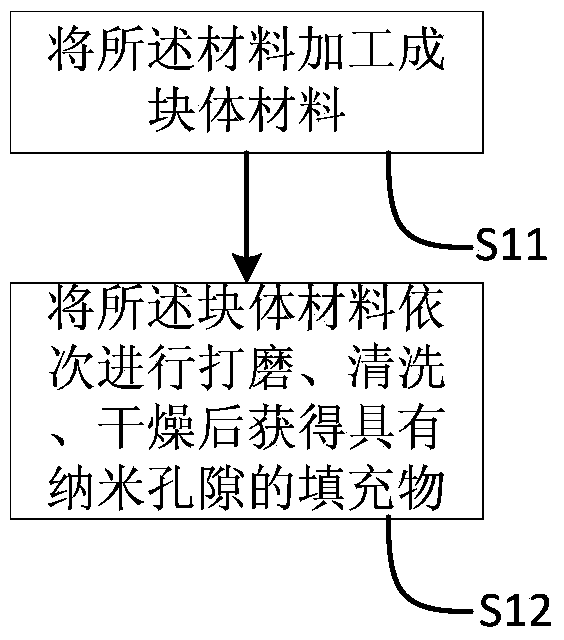

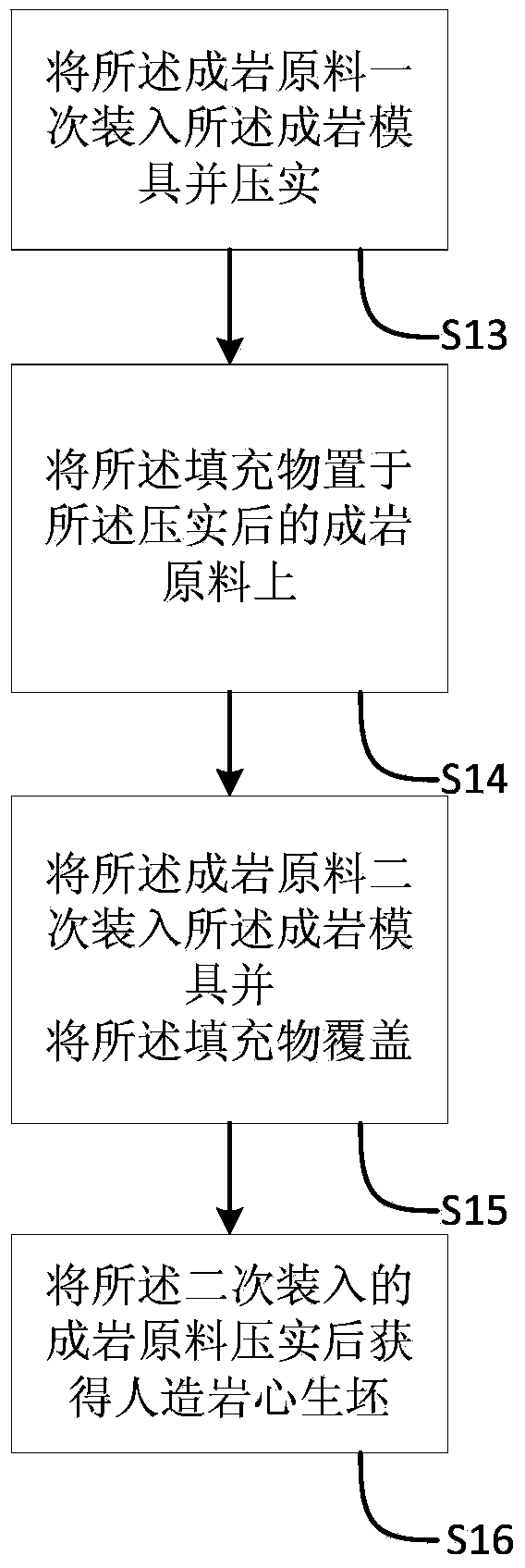

Method used

Image

Examples

Embodiment 1

[0068] Take a piece of zirconia nanoporous material, cut and drill to obtain 12 cylinders with a diameter of 2 mm and a length of 10 mm. The outer surface of the cylinder is polished with 1800 mesh sandpaper, cleaned with deionized water and absolute ethanol for 20 minutes, and then After vacuum drying at 80°C for 24 hours, a fixed-shaped filler, namely cylindrical nanoporous zirconia, was obtained;

[0069] Weigh 100g of solid glass beads with a particle size of 70 μm to 150 μm, wash them repeatedly with deionized water for 3 times, dry them with air, and fully mix them with 15 g of a uniform cement with potassium silicate: calcium silicate 100:2, and keep it before adding it to the mold. Stir to obtain 115g of evenly mixed diagenetic raw material;

[0070] Add 27 g of the obtained diagenetic raw material into a cylindrical diagenetic mold with a diameter of 30 mm, pre-compact it with a pressure of 20 MPa for 0.5 min, put 4 pieces of the obtained cylindrical nanoporous zircon...

Embodiment 2

[0074] Take a piece of zirconia nanoporous material, cut it, and use hollow drills of different diameters to drill a ring with an outer diameter of 30mm, an inner diameter of 27mm, and a height of 20mm. Ultrasonic cleaning for 20 minutes, followed by vacuum drying at 80°C for 24 hours to obtain a fixed-shaped filling, that is, a ring-shaped nanoporous zirconia;

[0075] Weigh 30g of solid glass beads with a particle size of 70μm to 150μm, wash them repeatedly with deionized water for 3 times, dry them with air, and fully mix them with 2g of cement with a uniform configuration of potassium silicate:calcium silicate 100:2, and keep it before adding it to the mold. Stir to obtain 32g of evenly mixed diagenetic raw materials;

[0076] Add 6 g of the obtained diagenetic raw material into a cylindrical diagenetic mold with a diameter of 30 mm, pre-compact it with a pressure of 20 MPa for 0.5 min, put the obtained annular nanoporous zirconia, fill the surrounding and inside with 26 g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com