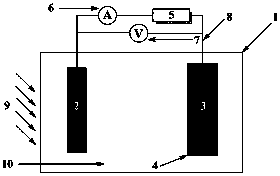

Constructing method and device for single-chamber medium-free algae microbial fuel cell

A fuel cell and construction method technology, applied in the direction of biochemical fuel cells, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of high cost, expensive electrode materials, and limiting the efficiency of microbial fuel cells, etc., to achieve simple installation, The effect of simple cultivation conditions and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of construction method of single-chamber medial-free algae microbial fuel cell, its steps are:

[0029] A, screening of algae microorganisms, screening algae microorganisms in natural water body, its steps are:

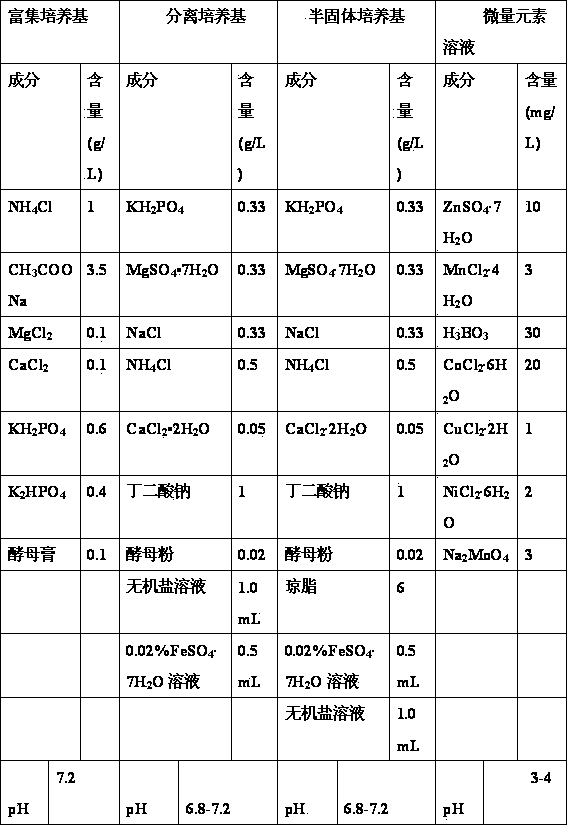

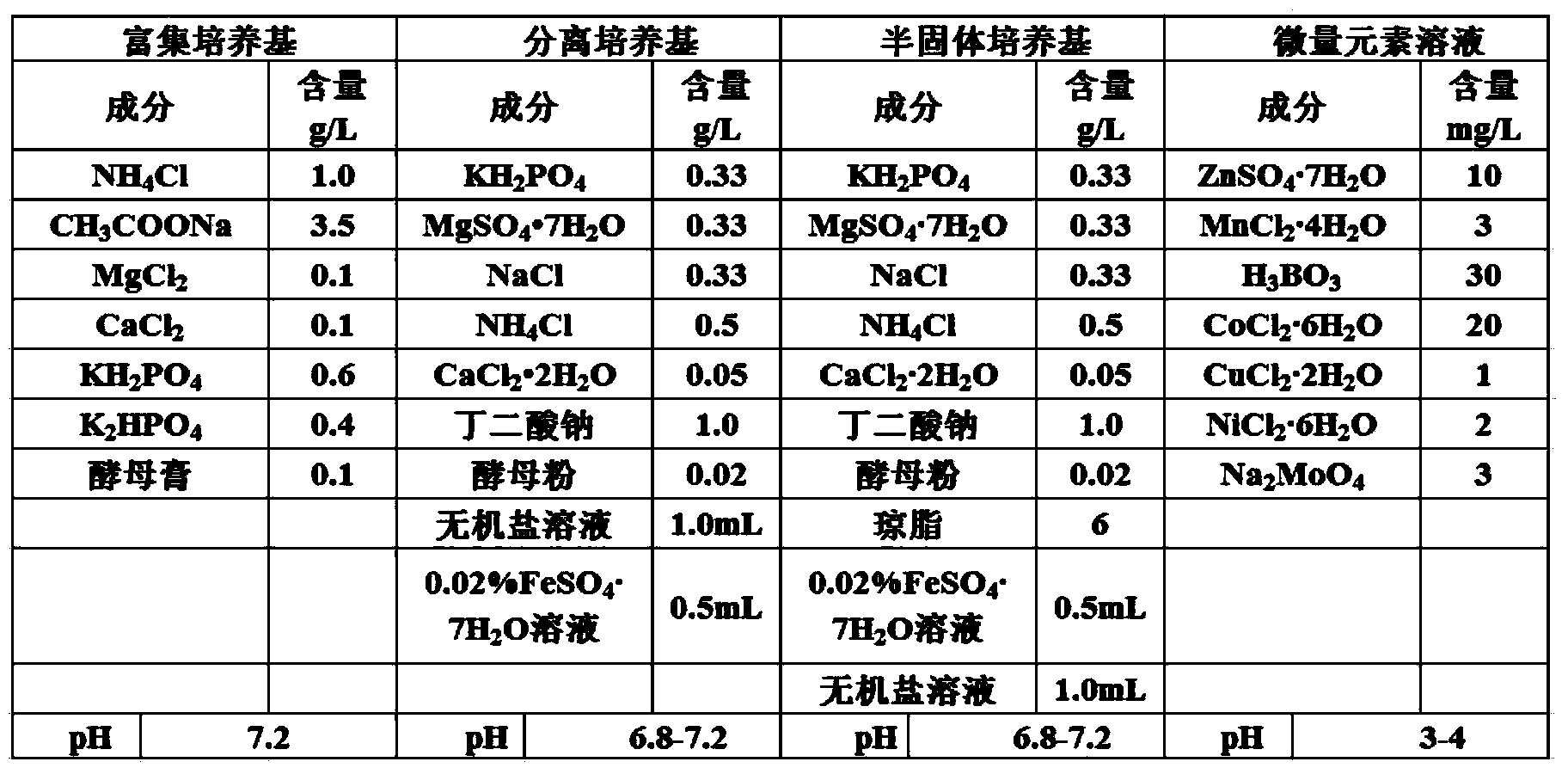

[0030] 1) Enrichment of algae microorganisms: add 15mL of enrichment medium that has been sterilized at 121°C for 18 or 19 or 20 or 21 or 22 minutes into a 18mm×180mm glass test tube, insert 1mL of natural water sample, shake evenly, add 1mL of liquid paraffin sterilized under the same conditions, stuffed into a rubber stopper and sealed with a parafilm, put the sealed test tube in a constant temperature light incubator, under the condition of an illumination of 3000lux and a temperature of 28 or 29 or 30 or 31 or 32°C Cultivate for 7 or 8 or 9 or 10 days until the culture medium turns green, transfer 1 mL of the enriched culture medium to another test tube filled with freshly sterilized enriched culture medium, and repeat the above operation 4, 5 or 6 t...

Embodiment 2

[0042] A method for constructing a single-chamber medial-free algae microbial fuel cell, the steps of which are:

[0043] A, screening of algae microorganisms, screening algae microorganisms in natural water body, its steps are:

[0044] 1) Enrichment of algae microorganisms: add 15mL of enrichment medium that has been sterilized at 121°C for 18 or 19 or 20 or 21 or 22 minutes into a 18mm×180mm glass test tube, insert 1mL of natural water sample, shake evenly, add 1mL of liquid paraffin sterilized under the same conditions, stuffed into a rubber stopper and sealed with a parafilm, put the sealed test tube in a constant temperature light incubator, under the conditions of an illumination of 3000lux and a temperature of 28 or 29 or 30 or 31 or 32°C Cultivate for 7 or 8 or 9 or 10 days until the culture medium turns green, transfer 1 mL of the enriched culture medium to another test tube containing freshly sterilized enriched culture medium, and repeat the above operation 4, 5 or...

Embodiment 3

[0056] A method for constructing a single-chamber medial-free algae microbial fuel cell, the steps of which are:

[0057] A, screening of algae microorganisms, screening algae microorganisms in natural water body, its steps are:

[0058] 1) Enrichment of algae microorganisms: add 15mL of enrichment medium that has been sterilized at 121°C for 18 or 19 or 20 or 21 or 22 minutes into a 18mm×180mm glass test tube, insert 1mL of natural water sample, shake evenly, add 1mL of liquid paraffin sterilized under the same conditions, stuffed into a rubber stopper and sealed with a parafilm, put the sealed test tube in a constant temperature light incubator, under the conditions of an illumination of 3000lux and a temperature of 28 or 29 or 30 or 31 or 32°C Cultivate for 7 or 8 or 9 or 10 days until the culture medium turns green, transfer 1 mL of the enriched culture medium to another test tube containing freshly sterilized enriched culture medium, and repeat the above operation 4, 5 or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum power density | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com