A hydrogen production reaction device for steam reforming of methanol

A steam reforming and reaction device technology, applied in the direction of hydrogen, inorganic chemistry, non-metallic elements, etc., can solve the problems that hinder the progress and development of methanol steam reforming hydrogen production micro-reactors, uneven fluid distribution, and insufficient technology Mature and other issues, to achieve the effect of improving hydrogen production efficiency, uniform fluid and temperature distribution, and high hydrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further illustrated and described below through specific embodiments in conjunction with the accompanying drawings.

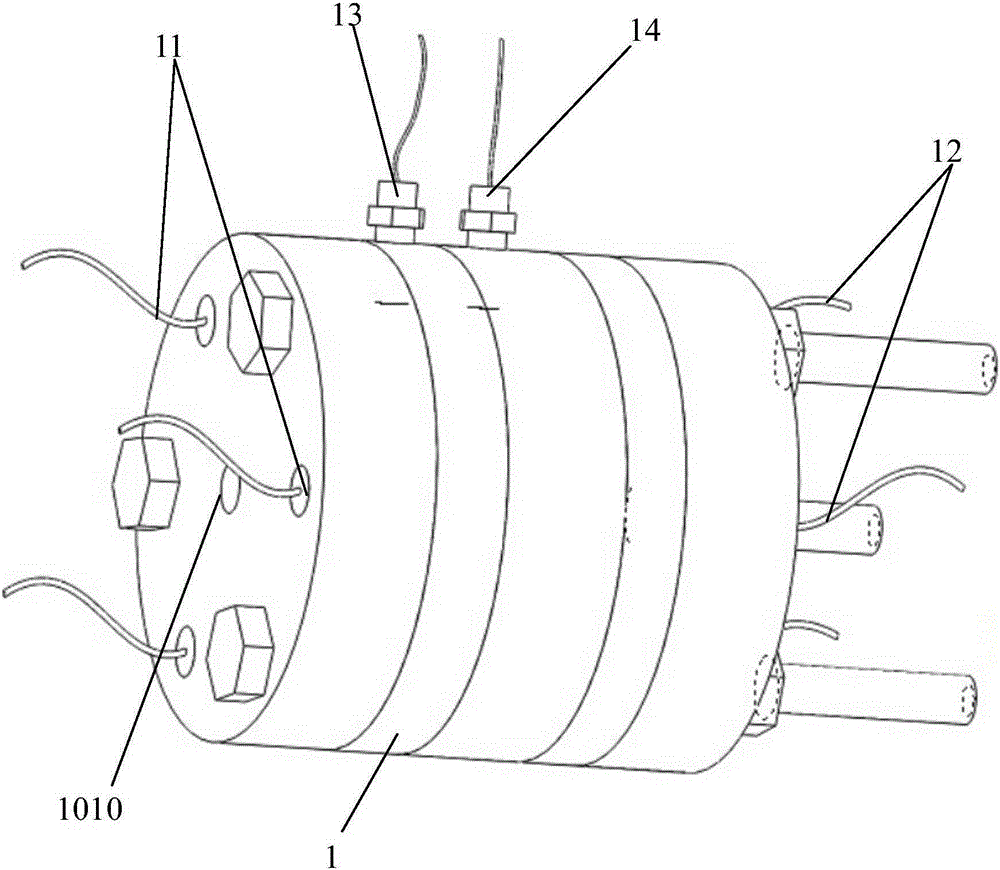

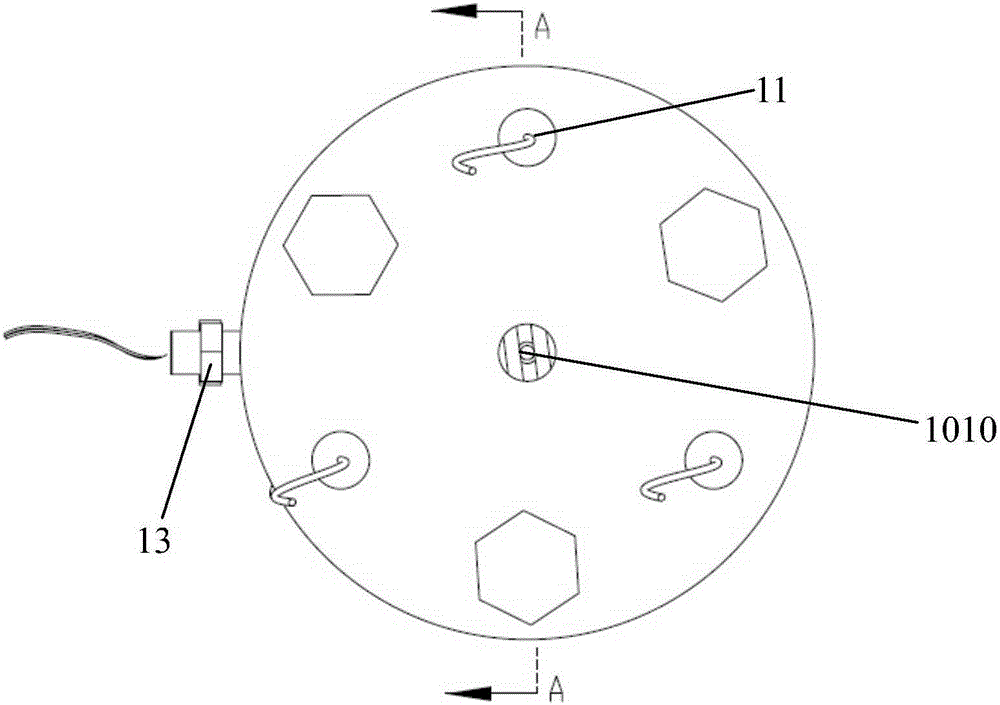

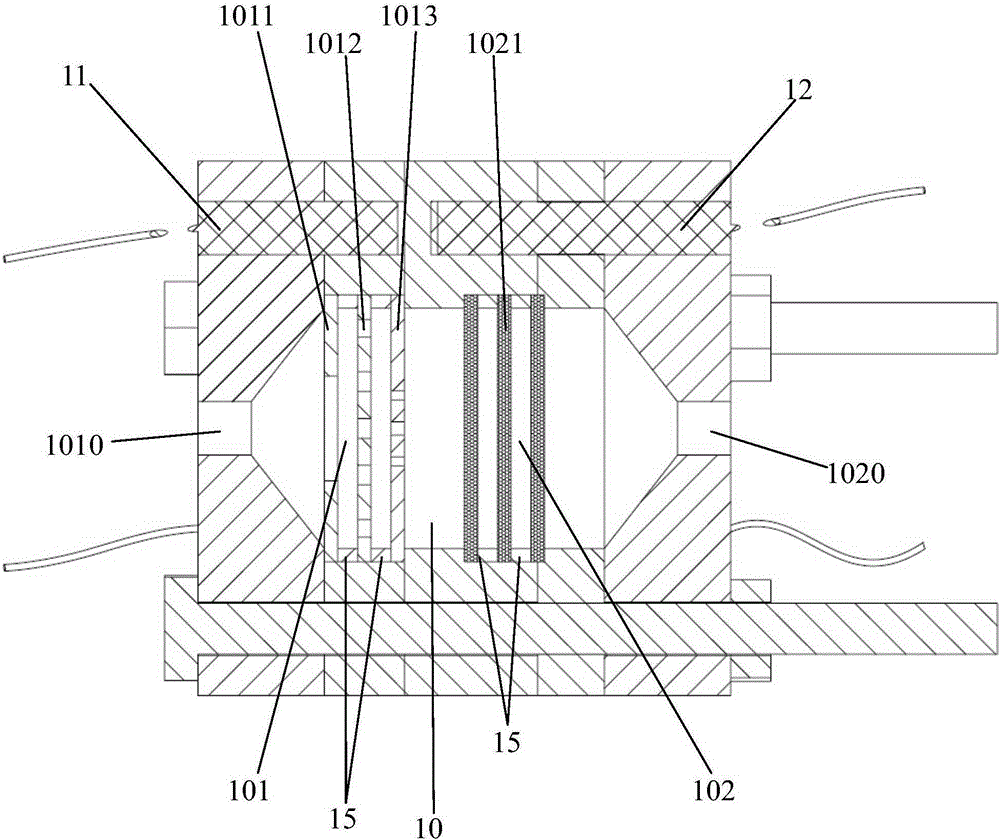

[0029] Such as Figure 1 to Figure 3 As shown, a methanol steam reforming hydrogen production reaction device includes a reactor body 1, a reaction chamber 10 is arranged in the reactor body 1, and a first heating device 11, a second heating device 11 are arranged on the reactor body 1 Two heating devices 12, the first thermocouple 13 and the second thermocouple 14, the cross-section of the reaction chamber 10 is circular, so that the overall flow direction of the fluid is a straight line, which can greatly reduce the reaction pressure drop, and from the left To the right, it is divided into an evaporating section 101 and a reforming section 102 with the same inner diameter. The first heating device 11 is connected to the evaporating section 101 to provide thermal energy for evaporation, and the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com