Technology for producing pure chlorogenic acid

A technology of pure chlorogenic acid, which is applied in the technical field of producing pure chlorogenic acid, can solve the problems of difficult membrane cleaning, high requirements for extract pretreatment, loss, etc., so as to save experimental costs and reduce subsequent processing Cost and usage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

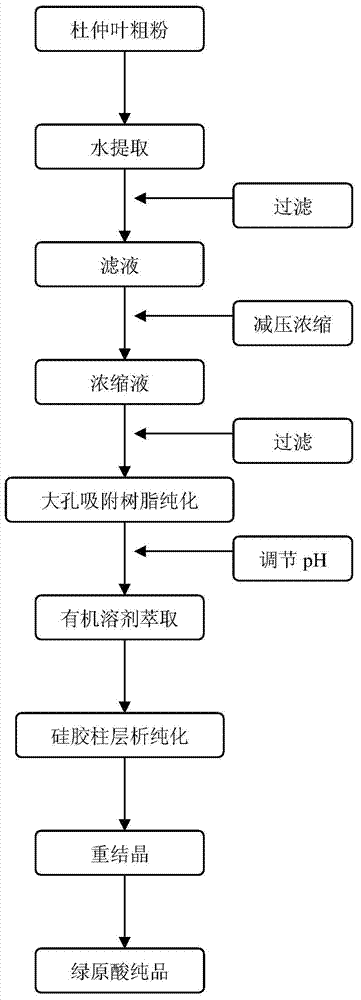

Image

Examples

Embodiment 1

[0033] (1) Using eucommia leaf powder and water as raw materials to prepare a concentrated solution of chlorogenic acid with a concentration of 0.8mg / mL for subsequent use; using water as an extraction solvent, dry eucommia leaf powder and water at a ratio of 1g:10mL , extracted in a water bath at 60°C for 60 minutes, the number of extractions was three times, the extracts were combined and filtered, and then the obtained filtrate was concentrated under reduced pressure and then filtered to obtain a concentrated solution of chlorogenic acid

[0034] (2) The chlorogenic acid water extraction concentrate obtained in step (1) is first purified by macroporous adsorption resin with NKAⅡ resin, washed with water to remove water-soluble impurities, and then desorbed to obtain a desorption solution, which is ethanol with a concentration of 40%. Aqueous solution, and then the desorption liquid is decompressed and concentrated to a paste to obtain a crude extract of chlorogenic acid; the v...

Embodiment 2

[0039] (1) Taking eucommia leaf powder and water as raw materials to prepare a concentrated solution of chlorogenic acid with a concentration of 1.2mg / mL for subsequent use; using water as an extraction solvent, dry eucommia leaf powder and water at a ratio of 1g:14mL , extracted in a water bath at 80°C for 40 minutes, the number of times of extraction was two times, the extracts were combined and filtered, and then the obtained filtrate was concentrated under reduced pressure and then filtered to obtain a concentrated solution of chlorogenic acid

[0040] (2) The chlorogenic acid water extraction concentrate obtained in step (1) is first purified by macroporous adsorption resin with NKAⅡ resin, washed with water to remove water-soluble impurities, and then desorbed to obtain a desorption solution. The analysis solution is ethanol with a concentration of 60%. Aqueous solution, and then concentrate the desorption liquid to a paste under reduced pressure to obtain the crude extra...

Embodiment 3

[0045] (1) Using eucommia leaf powder and water as raw materials to prepare a concentrated solution of chlorogenic acid with a concentration of 1.0mg / mL for subsequent use; using water as an extraction solvent, dry eucommia leaf powder and water at a ratio of 1g:12mL , extracted in a water bath at 70°C for 50 minutes, the number of extractions was three times, the extracts were combined and filtered, and then the obtained filtrate was concentrated under reduced pressure and then filtered to obtain a concentrated solution of chlorogenic acid

[0046] (2) The chlorogenic acid water extraction concentrate obtained in step (1) is first purified by using NKAⅡ resin for macroporous adsorption resin, then washed with water to remove water-soluble impurities, and then desorbed to obtain a desorption solution, which is ethanol with a concentration of 50%. aqueous solution, and then concentrate the desorption solution under reduced pressure to a paste to obtain the crude extract of chlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com