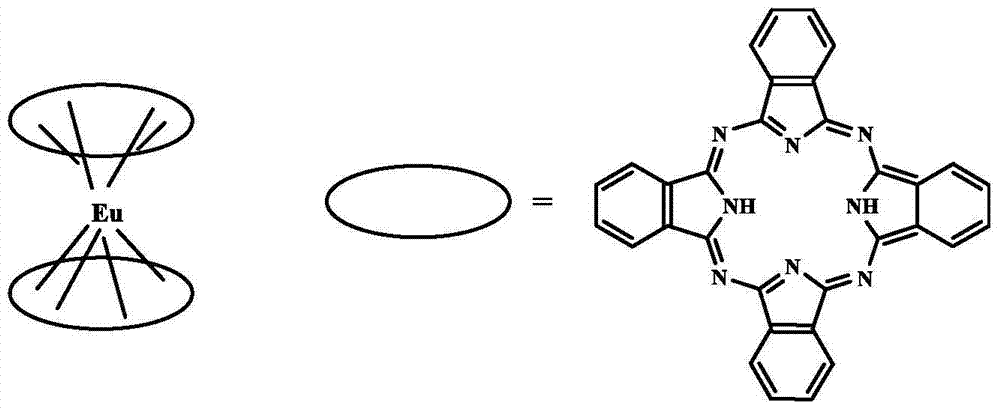

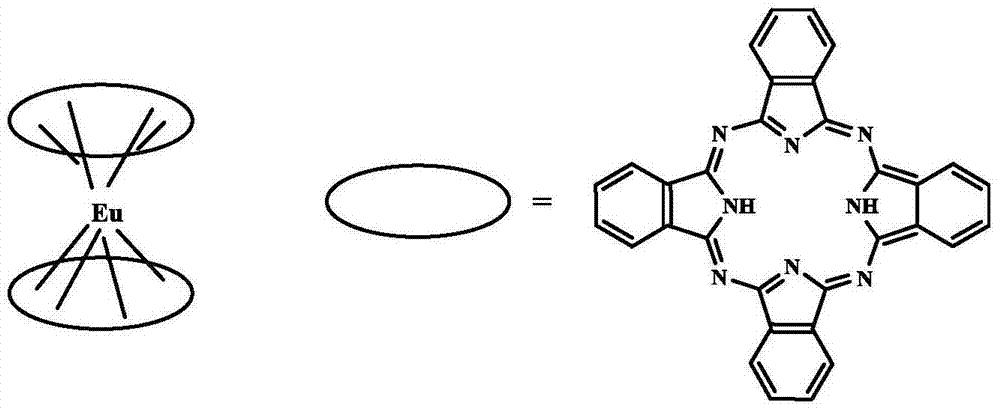

Application of double-layer sandwich-type Eu metal phthalocyanine complex in microcontact printing

A micro-contact printing, sandwich-type technology, applied in the application, metal material coating process, coating, etc., can solve the problems that have not been reported in the application, and achieve the effect of high resolution, low preparation cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The polytetrafluoroethylene substrate was soaked in 50% isopropanol aqueous solution for 30 minutes, then soaked in 3 mol / L sulfuric acid at 60°C for 15 minutes, then washed with water, and dried in vacuum at 60°C. Dissolve diphthalocyanine compound Eu in dichloromethane at a concentration of 1 g / L. Soak the PDMS stamp in the solution of diphthalocyanine and Eu in dichloromethane for 30s, take it out and put it in N 2 Dry in air flow for 30s. Cover the PDMS stamp coated with the solution of diphthalocyanine and Eu in dichloromethane on the carboxylated substrate, and press lightly for 10 seconds to transfer the PDMS stamp pattern to the surface of the substrate. Soak the printed substrate in 0.1g / LPdCl2 solution for 10s, take it out and place it in an electroless copper plating solution consisting of 5wt% copper sulfate, 7wt% sodium potassium tartrate, 6wt% sodium hydroxide, 32wt% formaldehyde and 50wt% distilled water Perform electroless plating for 3 minutes. Exqui...

Embodiment 2

[0026] The polytetrafluoroethylene substrate was soaked in 50% isopropanol aqueous solution for 30 minutes, then soaked in 3 mol / L sulfuric acid at 60°C for 15 minutes, then washed with water, and dried in vacuum at 60°C. Dissolve diphthalocyanine compound Eu in dichloromethane at a concentration of 3g / L. Soak the PDMS stamp in the solution of diphthalocyanine and Eu in dichloromethane for 30s, take it out and put it in N 2 Dry in air flow for 30s. Cover the PDMS stamp coated with the solution of diphthalocyanine and Eu in dichloromethane on the carboxylated substrate, and press lightly for 10 seconds to transfer the PDMS stamp pattern to the surface of the substrate. Soak the printed substrate in 0.1g / L PdCl2 solution for 10s, take it out and place it in an electroless copper plating solution consisting of 5wt% copper sulfate, 7wt% sodium potassium tartrate, 6wt% sodium hydroxide, 32wt% formaldehyde and 50wt% distilled water Electroless plating was carried out for 10 min. ...

Embodiment 3

[0028] The polytetrafluoroethylene substrate was soaked in 50% isopropanol aqueous solution for 30 minutes, then soaked in 3 mol / L sulfuric acid at 60°C for 15 minutes, then washed with water, and dried in vacuum at 60°C. Dissolve diphthalocyanine compound Eu with dichloromethane at a concentration of 5g / L. Soak the PDMS stamp in the solution of diphthalocyanine and Eu in dichloromethane for 30s, take it out and put it in N 2 Dry in air flow for 30s. Cover the PDMS stamp coated with the solution of diphthalocyanine and Eu in dichloromethane on the carboxylated substrate, and press lightly for 10 seconds to transfer the PDMS stamp pattern to the surface of the substrate. Soak the printed substrate in 0.1g / LPdCl2 solution for 10s, take it out and place it in an electroless copper plating solution consisting of 5wt% copper sulfate, 7wt% sodium potassium tartrate, 6wt% sodium hydroxide, 32wt% formaldehyde and 50wt% distilled water Perform electroless plating for 5 minutes. Exqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com