Electroconductive film and preparation method and application thereof

A technology for conductive thin films and electroluminescent devices, which is used in semiconductor/solid-state device manufacturing, circuits, electric light sources, etc., and can solve the problems of low work function of conductive thin films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

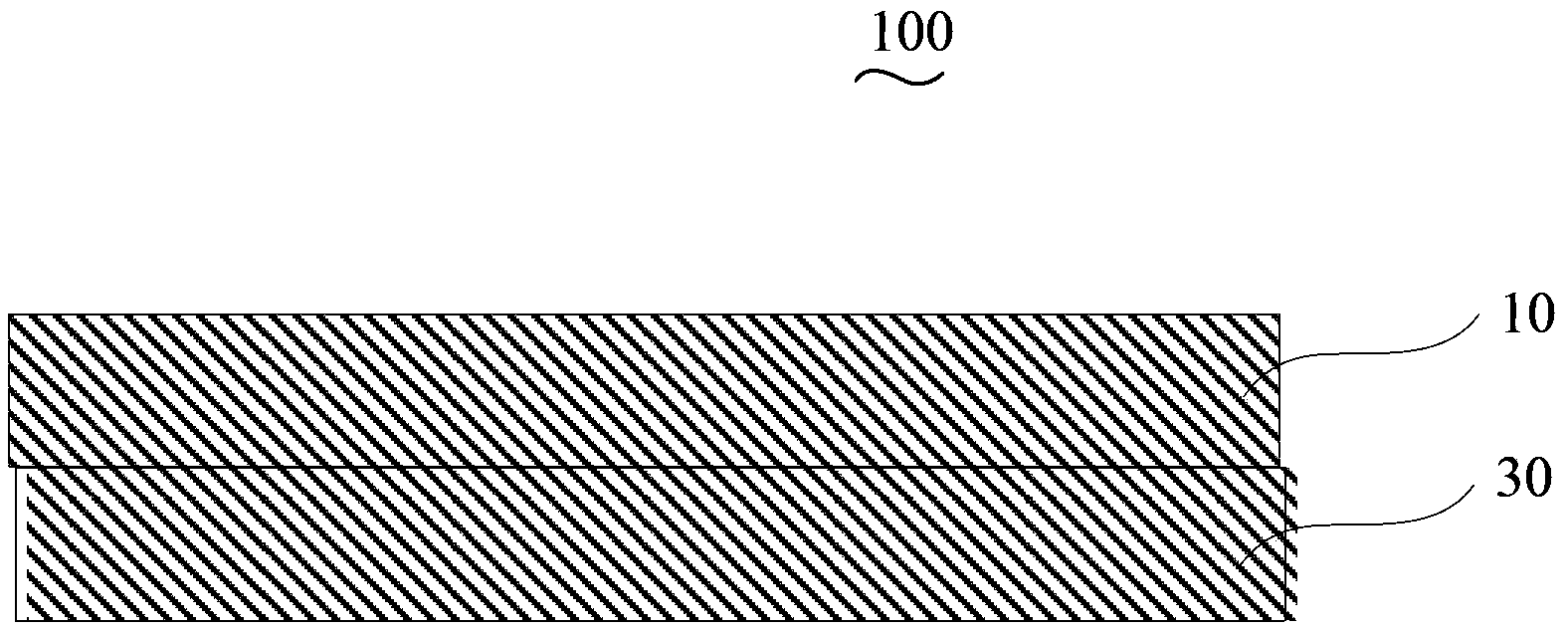

[0034] The preparation method of the above-mentioned conductive film 100 comprises the following steps:

[0035] S110, the TiO 2-x f x Target and Co 3 o 4The target and substrate are loaded into the vacuum chamber of the magnetron sputtering coating equipment, wherein the vacuum degree of the vacuum chamber is 1.0×10 -3 Pa~1.0×10 -5 Pa, wherein, x is 0.1-0.6.

[0036] In this embodiment, the TiO 2-x f x The target is obtained by the following steps: TiO 2 and TiF 4 The powder is mixed evenly, and the mixed powder is sintered at 900°C to 1300°C to make a target, wherein the TiF 4 The mole percentage of the powder in the mixture is 2.6%-17.6%.

[0037] The substrate is a glass substrate. Preferably, the substrate is ultrasonically cleaned with acetone, absolute ethanol and deionized water before use.

[0038] In this embodiment, the vacuum degree of the vacuum chamber is preferably 5×10 -4 Pa.

[0039] Step S120, sputtering TiO on the substrate surface 2-x f x La...

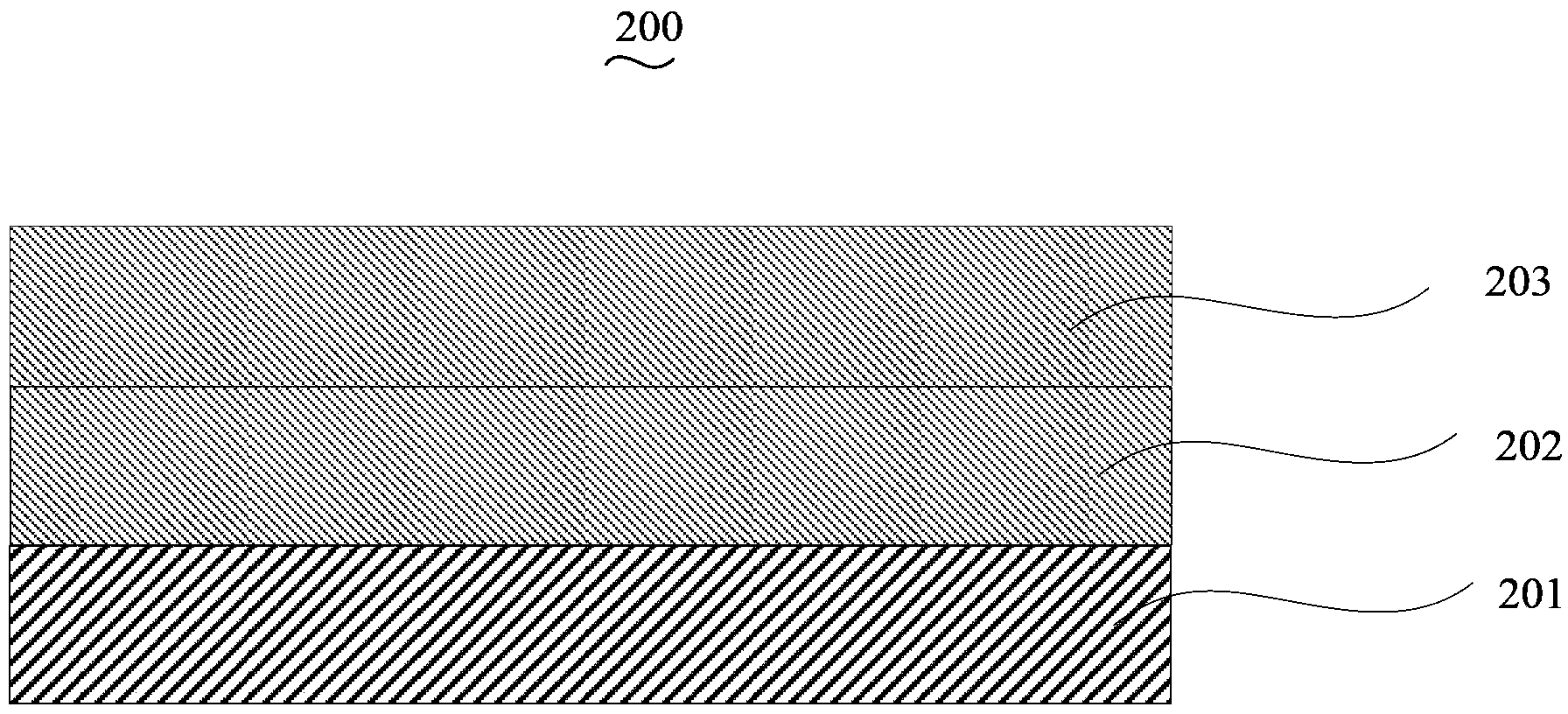

Embodiment 1

[0069] The powder with a purity of 99.9% is selected, and the TiO 2 and TiF 4 After the powder is uniformly mixed, it is sintered at 1250°C to form TiO with a diameter of 50 mm and a thickness of 2 mm. 1.6 f 0.4 Ceramic targets, among them, TiF 4 The molar percentage of the mixture is 12.5%, and the Co 3 o 4 The target material is loaded into the vacuum chamber. Then, the glass substrate was ultrasonically cleaned with acetone, absolute ethanol and deionized water successively, and placed in a vacuum chamber. The distance between the target and the substrate is set to 60mm. Use a mechanical pump and a molecular pump to pump the vacuum of the cavity to 5.0×10 -4 Pa, the working gas flow rate of argon is 20sccm, the pressure is adjusted to 10Pa, the substrate temperature is 500°C, and the laser energy is 150W. Sequentially sputtered TiO 1.6 f 0.4 Target and Co 3 o 4 Target material, respectively deposited 250nm and 15nm films to obtain TiO 1.6 f 0.4 -Co 3 o 4 Dou...

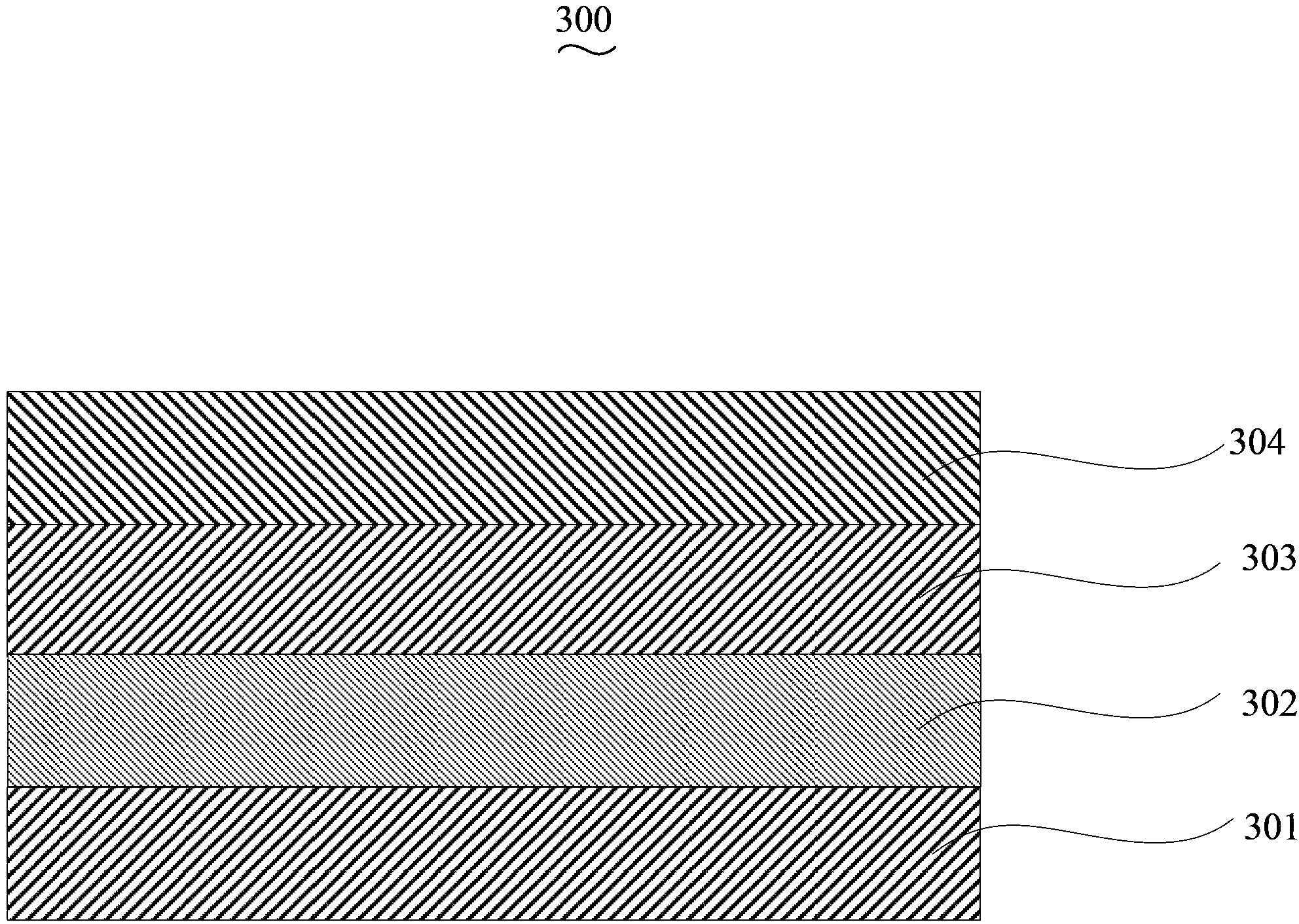

Embodiment 2

[0076] The powder with a purity of 99.9% is selected, and the TiO 2 and TiF 4 After the powder is uniformly mixed, it is sintered at 1350°C to form TiO with a diameter of 35mm and a thickness of 2mm. 1.9 f 0.1 Ceramic targets, among them, TiF 4 The mole percentage of the mixture is 2.6%, and the Co 3 o 4 The target material is loaded into the vacuum chamber. Then, the glass substrate was ultrasonically cleaned with acetone, absolute ethanol and deionized water successively, and placed in a vacuum chamber. The distance between the target and the substrate was set to 45 mm. Use a mechanical pump and a molecular pump to evacuate the vacuum of the chamber to 1.0×10 -5 Pa, the working gas flow rate of argon is 10 sccm, the pressure is adjusted to 3Pa, the substrate temperature is 250°C, and the laser energy is 300W. Sequentially sputtered TiO 1.9 f 0.1 Target and Co 3 o 4 Target material, respectively deposited 500nm and 5nm films to obtain TiO 1.9 f 0.1 -Co 3 o 4 M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap