Correcting method, correcting device and measuring apparatus for laser ranging

A technology of laser distance measurement and calibration method, applied in the direction of instruments, radio wave measurement systems, etc., can solve the problems of long circuit response time, easy mechanical failure, short service life, etc., to eliminate temperature drift, strengthen application, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The invention provides a calibration method for laser distance measurement, adopting two receiving systems to successively receive two kinds of light waves emitted by the transmitting device, through calibration, the temperature drift caused by ambient temperature and self-heating can be eliminated; at the same time, optical transmitting systems with different wavelengths and The optical filter group effectively separates the internal and external optical paths. Compared with the traditional dual-transmission and dual-reception scheme, the laser tubes of the same wavelength are placed at different positions or angles in the structure, which improves the compactness of the system and reduces the radio frequency crosstalk and interference caused by scattered emission.

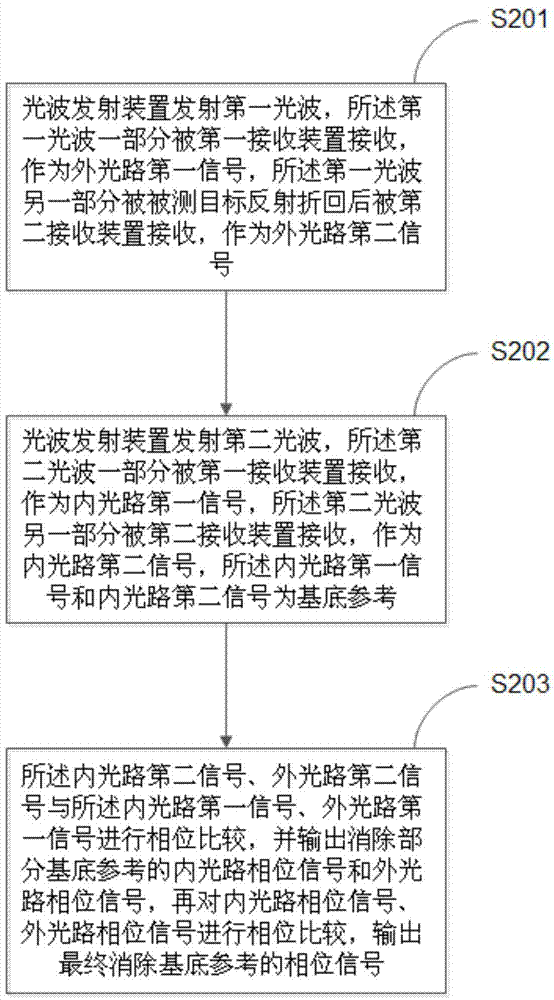

[0059] The implementation process of the laser ranging calibration method provided in this embodiment is as follows: figure 1 As shown, the details are as follows:

[0060] Step S 201 , the transmitting d...

Embodiment 2

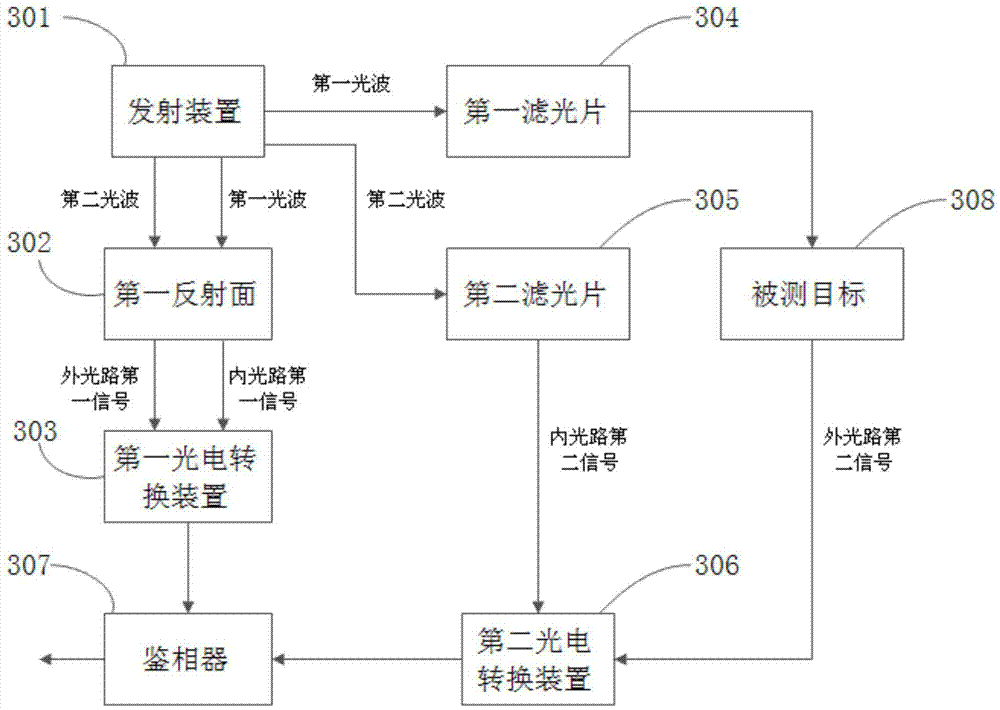

[0091] This embodiment provides a calibration device for laser ranging. The calibration device for laser ranging is based on the laser ranging calibration method of double-transmission, double-receiver, and dual-optical-path phase measurement, and adopts a dual-channel integrated transmitter. Its structural principle is as follows: image 3 As shown, for the convenience of description, this embodiment only provides the part related to the embodiment of the present invention.

[0092] A laser ranging calibration device provided in this embodiment includes an oscillator 401, a transmitting device 402, a first reflecting surface 403, a first photoelectric conversion device 404, a first optical filter 405, a second optical filter 406, The second photoelectric conversion device 407 , and the high frequency amplification device 408 , the mixer 409 , the low frequency amplification device 410 and the phase detector 411 .

[0093] Compared with the first embodiment, this embodiment di...

Embodiment 3

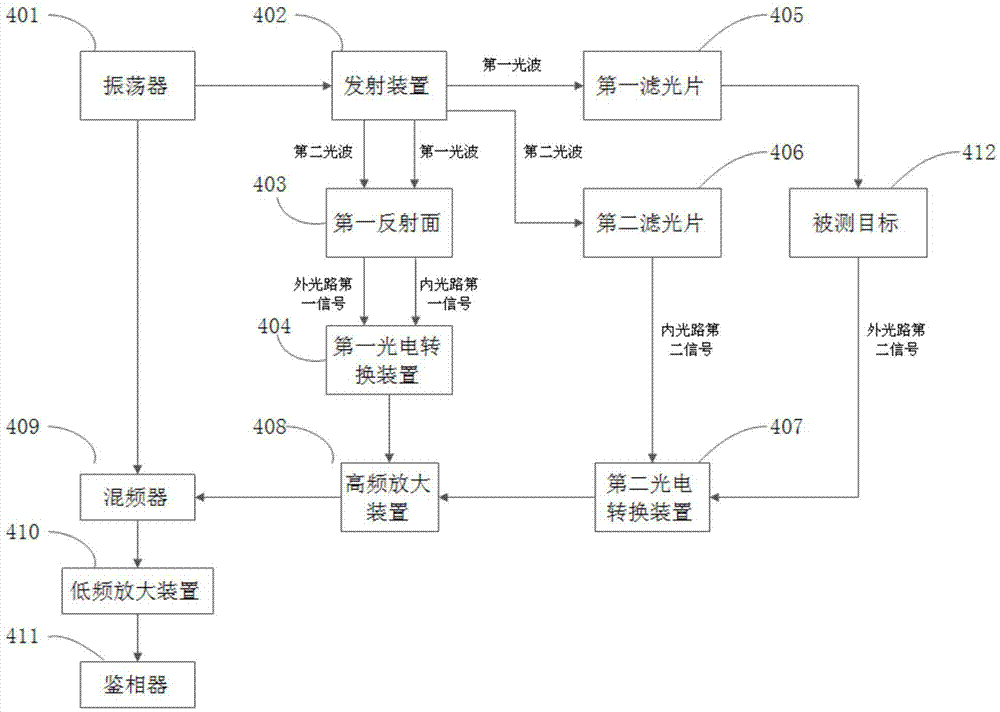

[0101] This embodiment provides a calibration device for laser ranging. The calibration device for laser ranging is based on the laser ranging calibration method of double-transmission, double-receiver, and dual-optical-path phase measurement, and adopts a dual-channel integrated transmitter. Its structural principle is as follows: Figure 4 As shown, for the convenience of description, this embodiment only provides the part related to the embodiment of the present invention.

[0102] Compared with Embodiment 2, this embodiment differs in that the first photoelectric conversion device 404 and the second photoelectric conversion device 407 are replaced by two receiving devices together with the mixer 409, and the receiving devices simultaneously implement the photoelectric conversion device 404 , 407 and mixer 409, the receiving device can be one or more photodiodes, phototransistors, APDs, PMTs (photomultiplier tubes) and other devices with photoelectric conversion functions. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com