Novel treatment technology of high-concentration industrial wastewater

A high-concentration technology for industrial wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as affecting the treatment effect, limited treatment effect, and difficult treatment of concentrated liquid , achieve good economic benefits, simple structure, improve efficiency and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

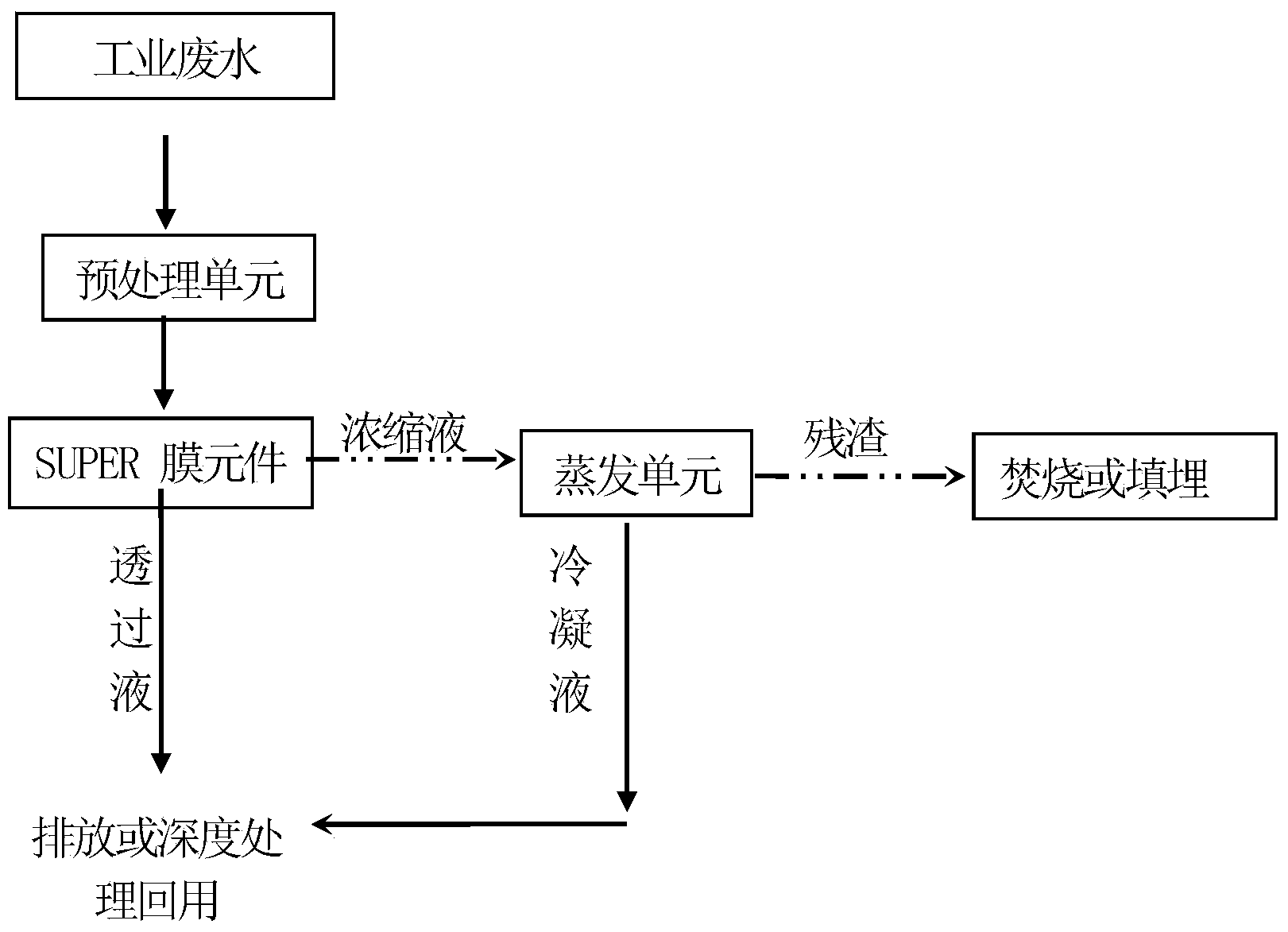

[0047] Such as figure 1 As shown, the new treatment technology for high-concentration industrial wastewater includes pretreatment unit, SUPER membrane element functional membrane unit and evaporation unit.

[0048] The pretreatment unit includes a wastewater regulating tank, a water pump and a filtration system, the filtration system is an ultrafiltration filtration system or a microfiltration filtration system or a sand filtration system, and the industrial wastewater is removed from colloids and suspended particles after passing through the pretreatment unit It becomes pre-treated wastewater, and then the pre-treated wastewater enters the SUPER membrane element functional membrane unit for the second step of treatment.

[0049] The functional membrane unit of the SUPER membrane element includes a water pump and a reverse osmosis membrane device. Under the action of the water pump, the pretreated wastewater is pumped into the reverse osmosis membrane device for reverse osmosi...

Embodiment 2

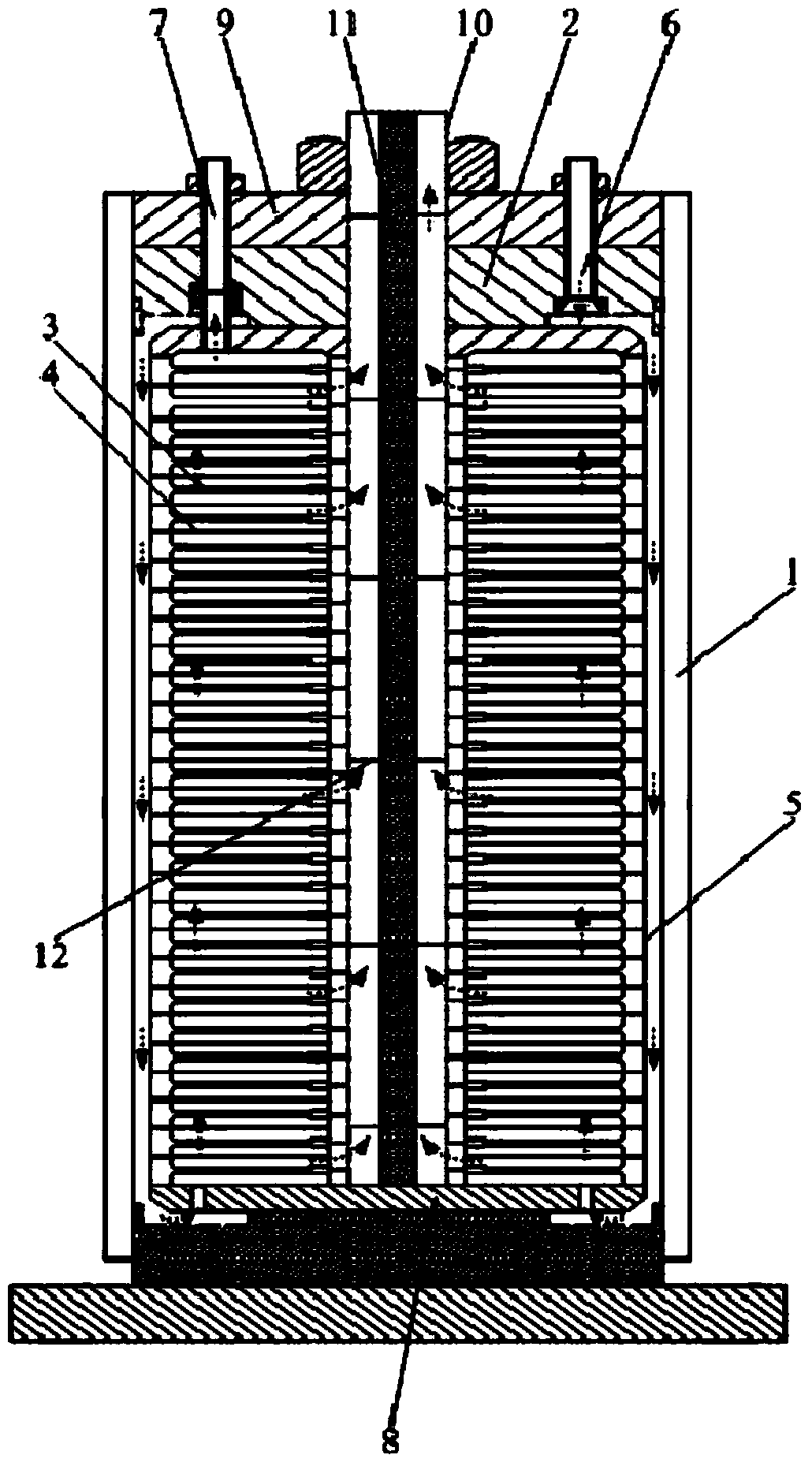

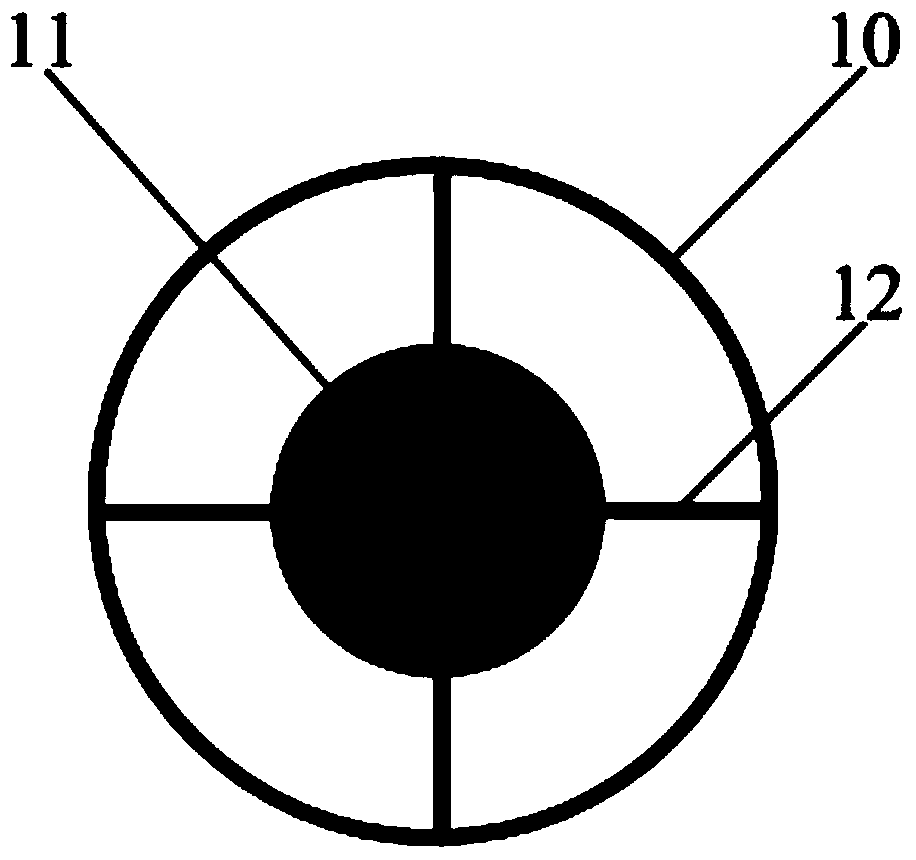

[0055] Such as figure 2 , 3 , 9, the sewage diversion filter device includes at least two diversion plates 1 and a diaphragm 10 used in conjunction with each other, wherein the diversion disc 1 and the diaphragm 10 are adjacent to each other, and the number of diversion discs 1 One more than the number of diaphragms 10, the guide plate 1 is a disc with a center hole 7 in the guide plate, and a boss is also arranged on the surface of the guide plate 1. On the guide plate 1 There are also two diversion slits 3 , and two orientation slits 13 matching the diversion slits 3 are arranged on the diaphragm 10 . There is a ring of protruding teeth 8 arranged along the radial direction on the outer side of the hole 7 of the above-mentioned deflector plate. The protruding teeth 8 are fixed on the inner edge of the deflector plate 1, and gaps are provided between the protruding teeth 8. The gaps are diversion gaps. , the setting positions of the upper and lower sides of the protruding ...

Embodiment 3

[0060] Such as Figure 4 , 5 As shown, the difference between this embodiment and Embodiment 1 lies in that the bosses are convex strips 9 , and the convex strips 9 are arranged on both sides of the deflector plate 1 in a certain arc in sequence. The convex line can better guide the dirty liquid, further reduce the pressure loss of the dirty liquid in the flow process, make better use of production resources, and reduce production loss; at the same time, the contact area between the convex line and the diaphragm Larger, which further reduces the force on the surface of the diaphragm, better avoids the damage of the diaphragm during use, improves the service life of the diaphragm, reduces the maintenance frequency during use, and greatly improves the use effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com