Preparation method of hollow polyimide composite microspheres

A technology of composite microspheres and polyimides, which is applied in the preparation of microspheres and microcapsule preparations, can solve the problems of large consumption of solvents, difficulty in removing thermal surfactants, and easy damage to internal structures by solvents, so as to avoid Effects of thermal properties and easy morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

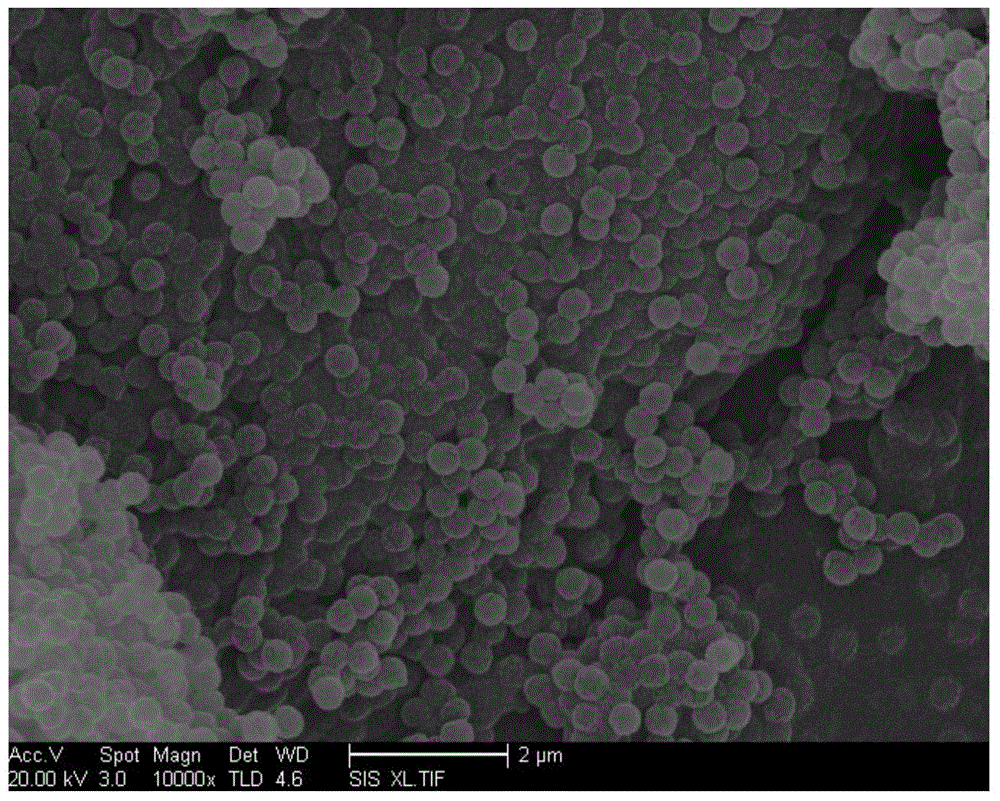

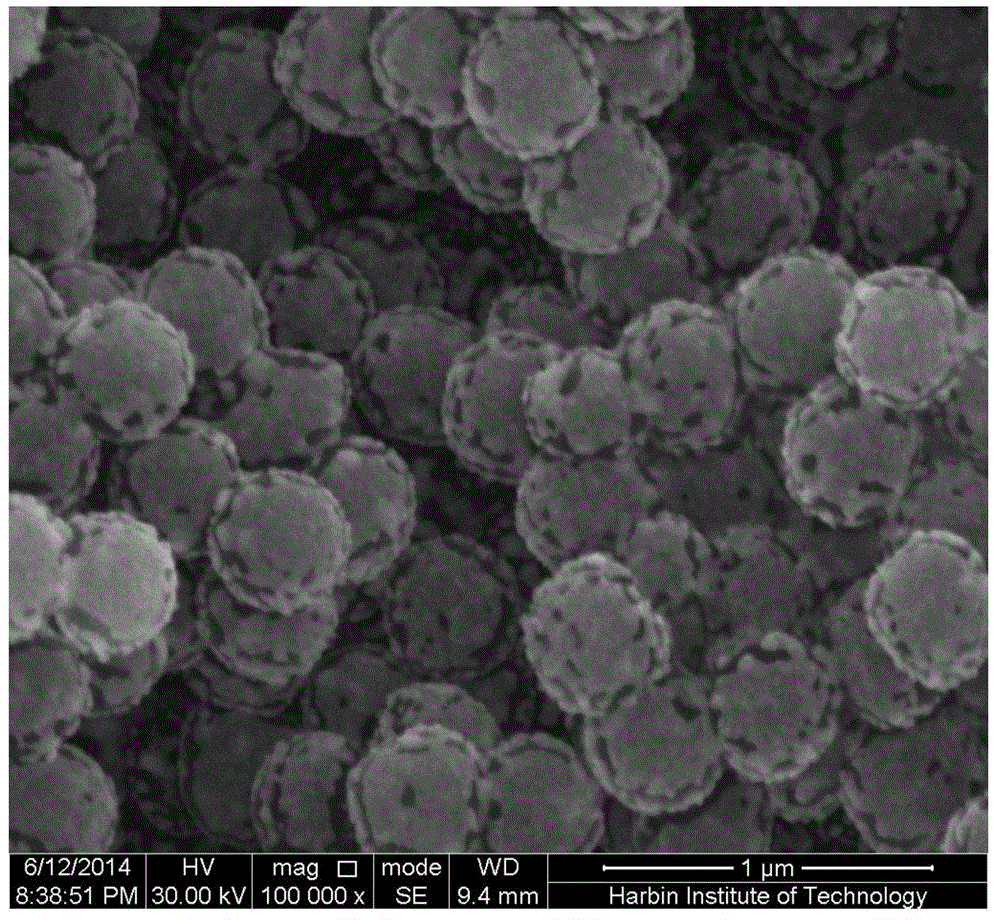

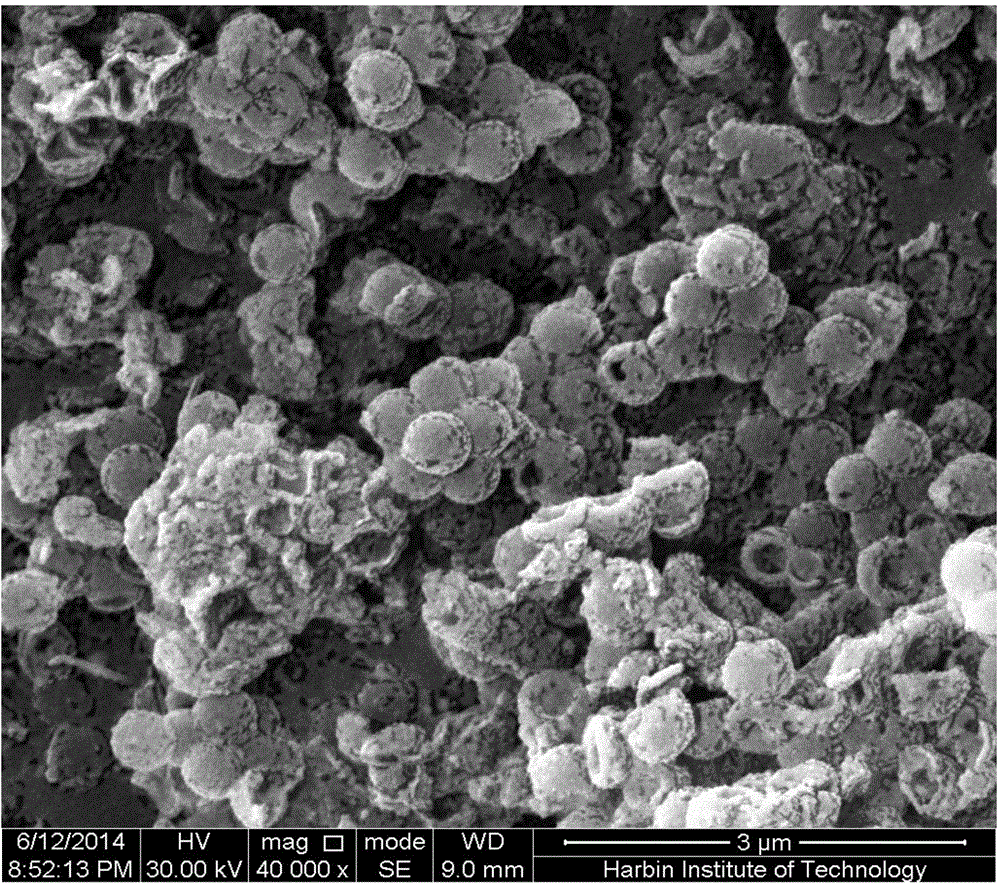

[0024] Specific embodiment one: the preparation method of the polyimide composite microsphere of a kind of hollow structure described in the present embodiment is to carry out according to the following steps:

[0025] 1. Mix the polystyrene microsphere solution and the pyrrole monomer under the condition of magnetic stirring, then add ferric chloride, and stir magnetically for 8h to 12h to obtain the polypyrrole-coated polystyrene composite microsphere solution, which will be obtained The solution of polypyrrole-coated polystyrene composite microspheres is subjected to centrifugation, and after centrifugation, the solid is washed with ethanol for 2 to 4 times and then dried to obtain polypyrrole-coated polystyrene composite microspheres; the polystyrene microspheres The solid content is 5%; The volume ratio of described polystyrene microsphere solution and pyrrole monomer is 1:(0.1~0.5); The volume ratio of the quality of described iron trichloride and polystyrene microsphere ...

specific Embodiment approach 2

[0036] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the volume ratio of polystyrene microspheres and pyrrole monomers in step 1 is 1:0.125. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the volume ratio of polystyrene microspheres and pyrrole monomers in step one is 1:0.2. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com