Industrialization device and method for preparation of nitride monocrystal material

A single crystal material and nitride technology, applied in the growth of polycrystalline materials, chemical instruments and methods, single crystal growth, etc., can solve the problems of hindering N2, slow crystal growth, single channel, etc., to increase the growth rate and supply time. Controllable and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

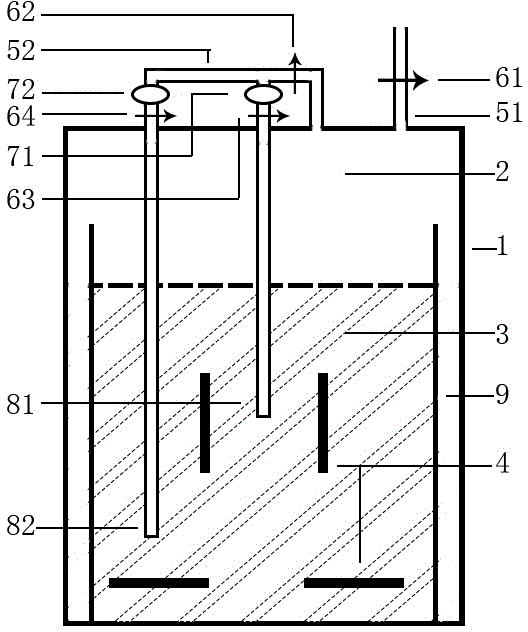

[0040] One is equipped with a built-in N 2 supply device (N 2 The input terminal port is multi-pointed in the vertical direction) industrialized device for nitride single crystal material, including the new built-in N 2 Supply facility and industrialization facility for conventional nitride single crystal materials. Such as figure 1 shown, the built-in N 2 Supply device comprises high position pressurizing device 71, low position pressurizing device 72, N 2 Circulation channel valve 62, N 2 Circulation channel high sub-valve 63, N 2 Circulation channel low sub-valve 64, N 2 Circulation channel 52, high position for N 2 Terminal port 81 and low bit for N 2 Terminal port 82; traditional nitride single crystal material industrialization device includes reactor body 1, crucible 9, N 2 Input channels 51 and N 2 Channel valve 61 . Place four gallium nitride substrates as the seed crystal template 4 horizontally / vertically inside the crucible 9, the target thickness of the...

Embodiment 2

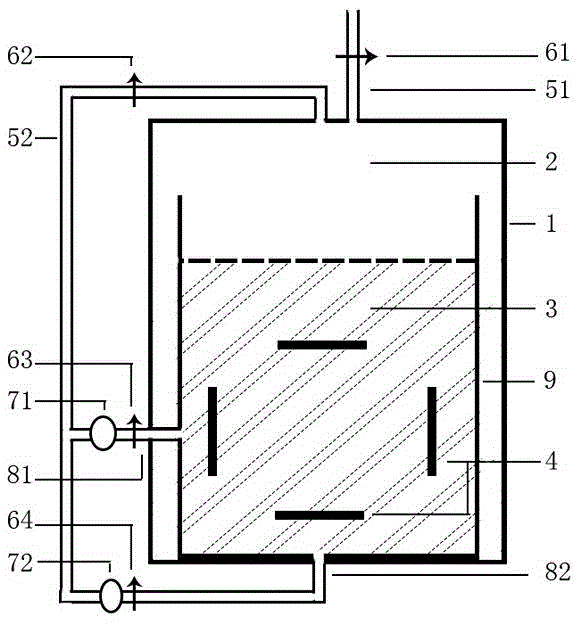

[0042] One equipped with an external N 2 supply device (N 2 The input terminal port is multi-pointed in the vertical direction) industrialized device for nitride single crystal material, including a new type of external N 2 Supply facility and industrialization facility for conventional nitride single crystal materials. Such as figure 2 shown, the external N 2 Supply device comprises high position pressurizing device 71, low position pressurizing device 72, N 2 Circulation channel valve 62, N 2 Circulation channel high sub-valve 63, N 2 Circulation channel low sub-valve 64, N 2 Circulation channel 52, high position for N 2 Terminal port 81 and low bit for N 2 Terminal port 82; traditional nitride single crystal material industrialization device includes reactor body 1, crucible 9, N 2 Input channels 51 and N 2 Channel valve 61 . Place four gallium nitride substrates as the seed crystal template 4 horizontally / vertically inside the crucible 9, the target thickness o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com