Surface tension and surface area viscosity measuring device

A technology of surface area and surface tension, applied in surface tension analysis, measuring devices, surface/boundary effects, etc., can solve problems such as slow surface tension, complex data processing, and limited use range, so as to improve accuracy and precision, The effect of high measurement accuracy and less sample consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

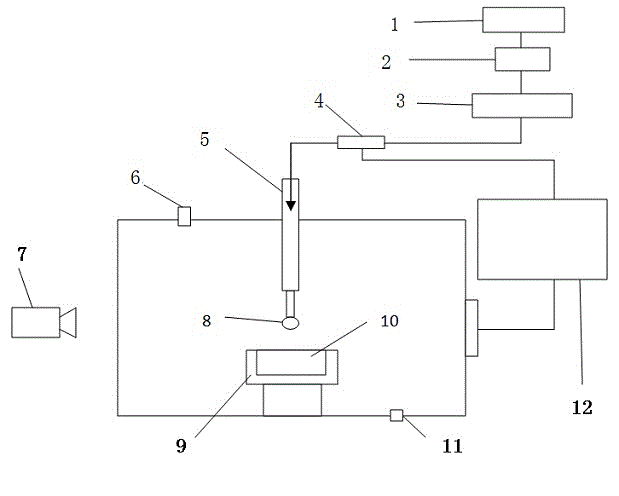

[0053] see Figure 1 to Figure 4 , a surface tension and surface area viscosity measuring device, comprising a capillary 5, the capillary 5 is vertically inserted into a sealed test box, and vertically installed on the test box shell, the material of the capillary 5 is different from that of the liquid sample 10 to be tested Reaction occurs, in the test box, an open container 9 for loading the liquid sample 10 to be tested is arranged directly below the bottom of the capillary 5, the material of the open container 9 does not react with the liquid sample 10 to be tested, and the open container 9 is installed On the stage, control the stage to move up and down, make the bottom end of the capillary 5 touch or break away from the liquid sample 10 to be tested, dip the bottom end of the capillary 5 to pick up the liquid sample 10 to be tested, and the experimental gas is supplied from the gas cylinder 1 It is transported into the capillary 5, and the pressure in the capillary 5 and...

Embodiment 2

[0071] This embodiment is basically the same as Embodiment 1, especially in that:

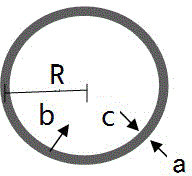

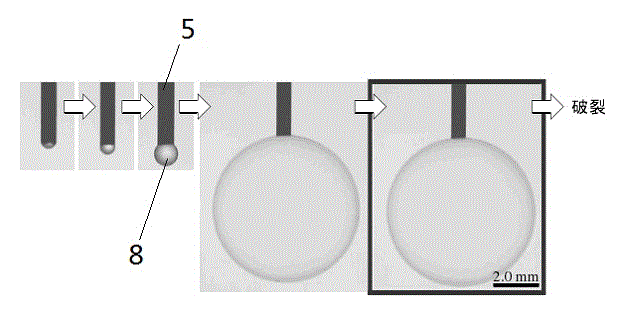

[0072] see Figure 1 to Figure 4, the device of this embodiment utilizes the differential pressure inside and outside the real spherical bubble to measure the viscosity of the liquid surface area, and a camera is also arranged outside the test box, and the controller controls the camera so that the camera takes the bubble 8 generated at the bottom of the capillary 5 as the shooting and recording target. The image acquisition of the formation process and shape of the bubble 8 is carried out, and then the radius R of the bubble 8 is measured in real time. In this way, the pressure difference between the inside and outside of the bubble 8 can be directly read, which greatly simplifies the calculation of the surface tension, and at the same time improves the accuracy and precision of the experimental measurement data.

[0073] In this example, see Figure 1 to Figure 4 , using the present embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com