Anisotropic nanocrystalline NdFeB magnet and its preparation method and application

An anisotropic, NdFeB technology, used in magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of corrosion resistance and fracture toughness decline, and achieve excellent magnetic density and magnetic properties. The effect of organizational structure and good magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

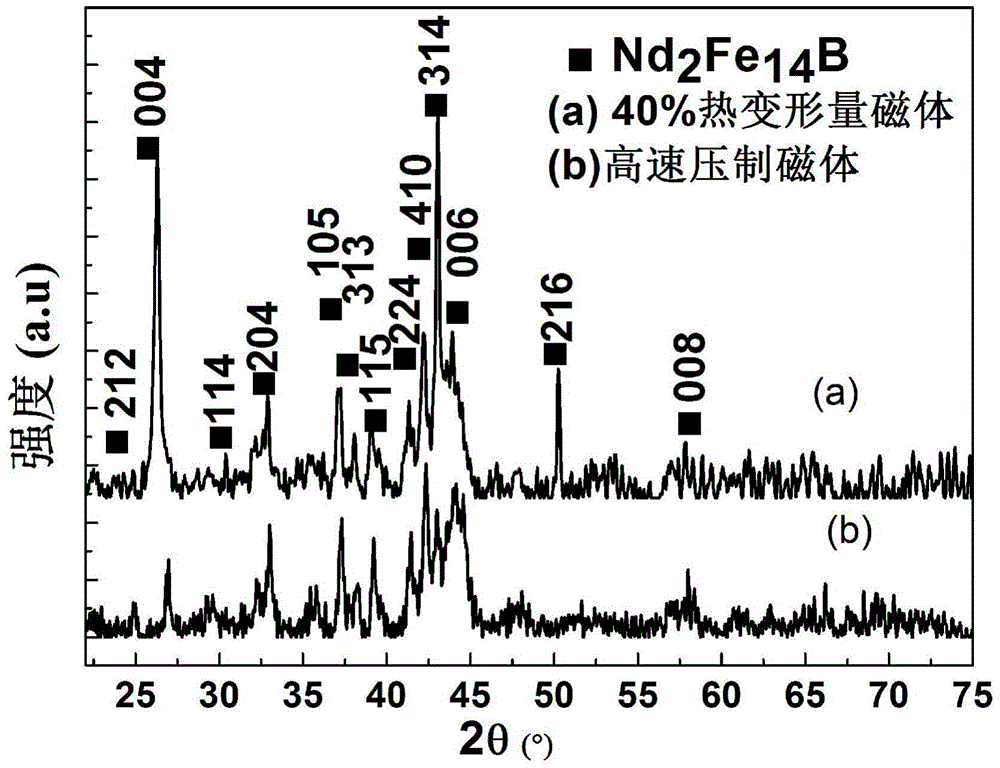

[0049] An anisotropic nanocrystalline NdFeB magnet, the preparation method of which is as follows:

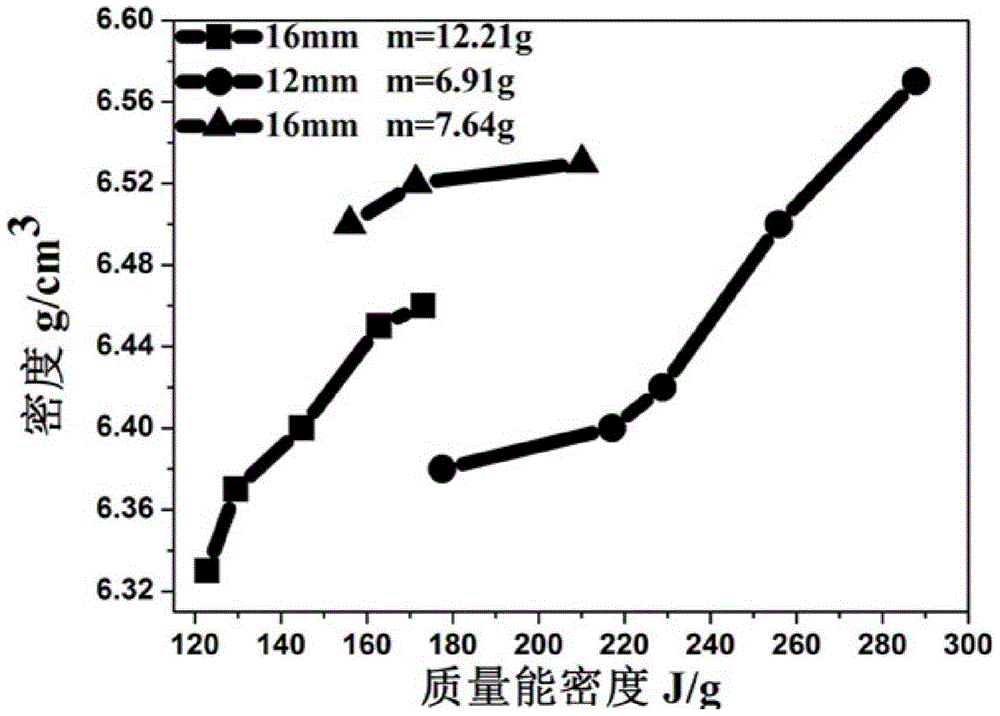

[0050] (1) Prepare NdFeB flake powder, the mass fractions of main elements are 29.2wt% Nd, 69.8wt% (FeCoAl), 1wt% B; choose a pressing mold with an inner diameter of Ф = 16mm, in the mold cavity and the upper and lower mold rods Apply the zinc stearate alcohol solution evenly, and after the alcohol evaporates, carefully put the prepared NdFeB flake powder into the mold cavity, and shake the mold to distribute the powder as evenly as possible. The amount of powder loaded is m=12.21 g;

[0051] (2) Adjust the impact energy E of the high-speed press according to the mass energy density, record the instantaneous speed at which the impact hammer impacts the upper die rod, and determine the impact energy. Adopt high-speed pressing twice, select impact energy E=320J for the first time, second time E=386J to carry out high-speed pressing; Adopt high-speed pressing once, adopt five kin...

Embodiment 2

[0054] An anisotropic nanocrystalline NdFeB magnet, the preparation method of which is as follows:

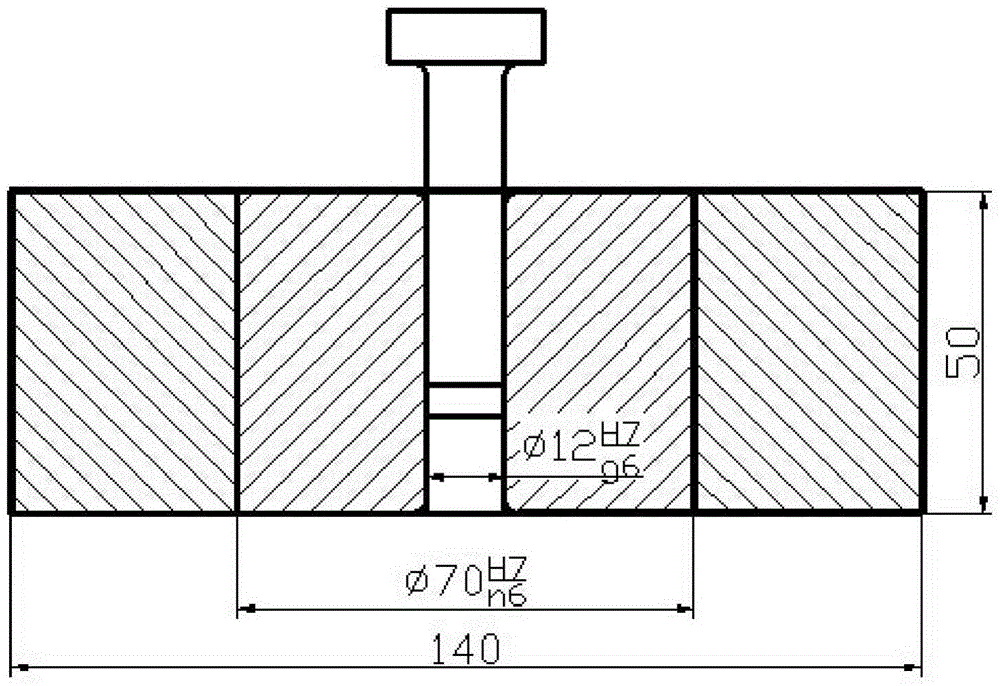

[0055] (1) Prepare NdFeB flake powder, the mass fractions of the main elements are 29.2wt% Nd, 69.8wt% (FeCoAl), 1wt% B; choose a pressing mold with an inner diameter of Ф = 12mm, in the mold cavity and the upper and lower mold rods Evenly coat the zinc stearate alcohol solution. After the alcohol evaporates, carefully put the prepared NdFeB flake powder into the mold cavity, and shake the mold to distribute the powder as evenly as possible. The amount of powder loaded is m=6.91 g; The assembly diagram of the pressing mold with inner diameter Ф = 12mm is as follows figure 1 shown;

[0056] (2) Adjust the impact energy E of the high-speed press according to the mass energy density, record the instantaneous speed at which the impact hammer impacts the upper die rod, and determine the impact energy. Adopt five kinds of impact energies of 1227J, 1500J, 1581J, 1768J and 1988J to c...

Embodiment 3

[0059] An anisotropic nanocrystalline NdFeB magnet, the preparation method of which is as follows:

[0060] (1) Prepare NdFeB flake powder, the mass fractions of the main elements are 30.2wt% Nd, 68.8wt% (FeCoAl), 1wt% B; choose a pressing mold with an inner diameter of Ф = 16mm, in the mold cavity and the upper and lower mold rods Evenly coat the zinc stearate alcohol solution. After the alcohol evaporates, carefully put the prepared NdFeB flake powder into the mold cavity, and shake the mold to distribute the powder as evenly as possible. The amount of powder loaded is m=7.69 g;

[0061] (2) Adjust the impact energy E of the high-speed press according to the mass energy density, record the instantaneous speed at which the impact hammer impacts the upper die rod, and determine the impact energy. Adopt successively three kinds of impact energies of 1191J, 1309J and 1605J to carry out high-speed pressing to the mold of step (1), then demoulding takes out the pressed sample;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic energy product | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com