Preparation method of acid-modified caustic-calcined magnesite/pulverized fuel ash water treatment agent

A technology of lightly burning magnesium powder and fly ash, which is applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. Achieve low cost, stable product performance and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment, the present invention is described in further detail.

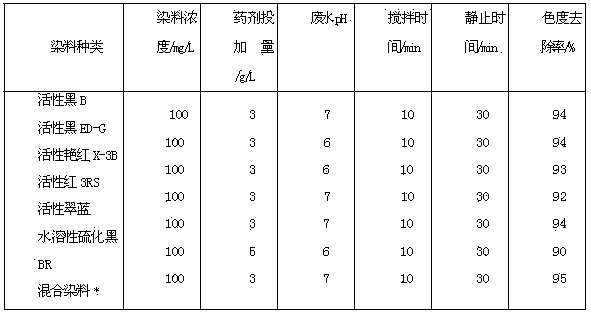

[0017] Add 150g of lightly burned magnesium powder (65% MgO content) and 150g of fly ash into a 500mL large beaker, slowly add 360mL of industrial hydrochloric acid with a mass fraction of 12%, stir while adding and heat to 450C in a water bath, continue stirring and mixing for 30min, After resting and activating for 40 minutes, heat and dry to constant weight, and grind it into powder after cooling, which is the prepared light-burned magnesium / fly ash water treatment agent product. This product is used to treat simulated wastewater of five kinds of reactive dyes and mixed dyes commonly used in printing and dyeing factories, and a good treatment effect has been received. The processing results are shown in Table 1.

[0018] Table 1 water treatment agent decolorization effect on various dye wastewater

[0019]

[0020] Mixed dye*: It is a mixture of equal volumes of the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com