Subsurface wetland with effluent N/P suitable for culturing non-toxic green alga

A technology of subsurface wetlands and green algae, applied in the field of environmental engineering, can solve problems such as water pollution, achieve the effects of inhibiting proliferation, reducing COD, and good economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

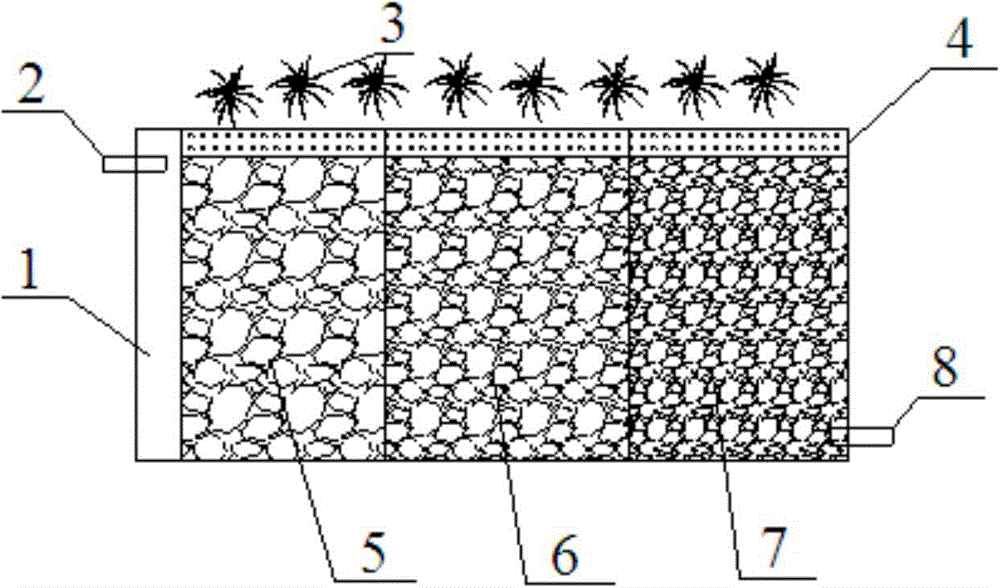

[0043] A subsurface wetland with effluent N / P suitable for the cultivation of non-toxic green algae, such as figure 1 As shown, including the treatment pool, water inlet 2 and water outlet 8 are respectively set at the front and back of the treatment pool. The interior of the treatment pool is sequentially composed of wetland plant layer 3, soil layer 4 and filler medium layer from top to bottom, and the filler medium layer is according to the direction of water flow. It is divided into a pre-treatment area 5, an intermediate treatment area 6 and a post-treatment area 7. The pre-treatment area 5, the intermediate treatment area 6 and the post-treatment area 7 respectively contain zeolite and steel slag in different proportions. A buffer zone 1 is provided in front of the treatment tank, a water inlet 2 is located in the upper area of the buffer zone 1, and a water outlet 8 is located in the lower area of the post-treatment area 7 .

[0044] The working parameters of the pr...

Embodiment 2

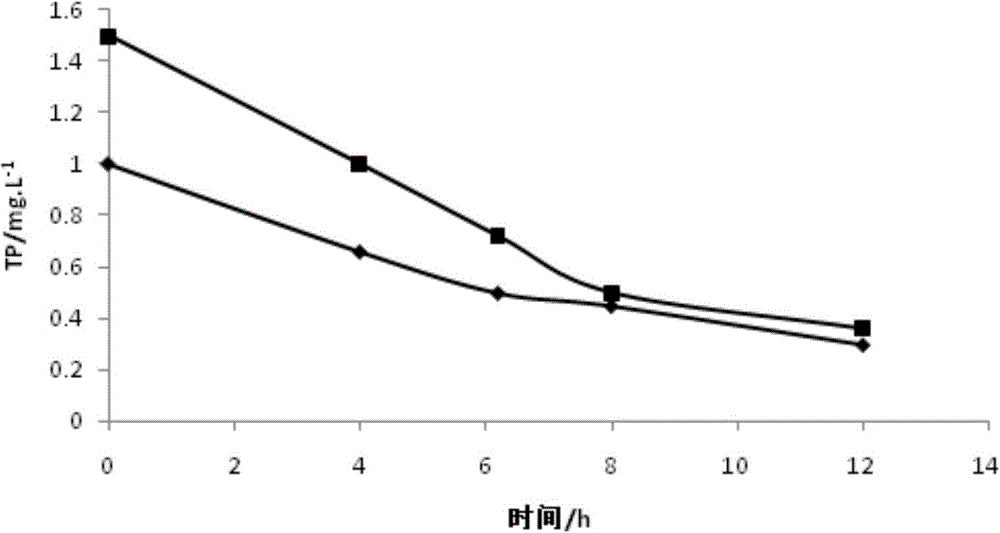

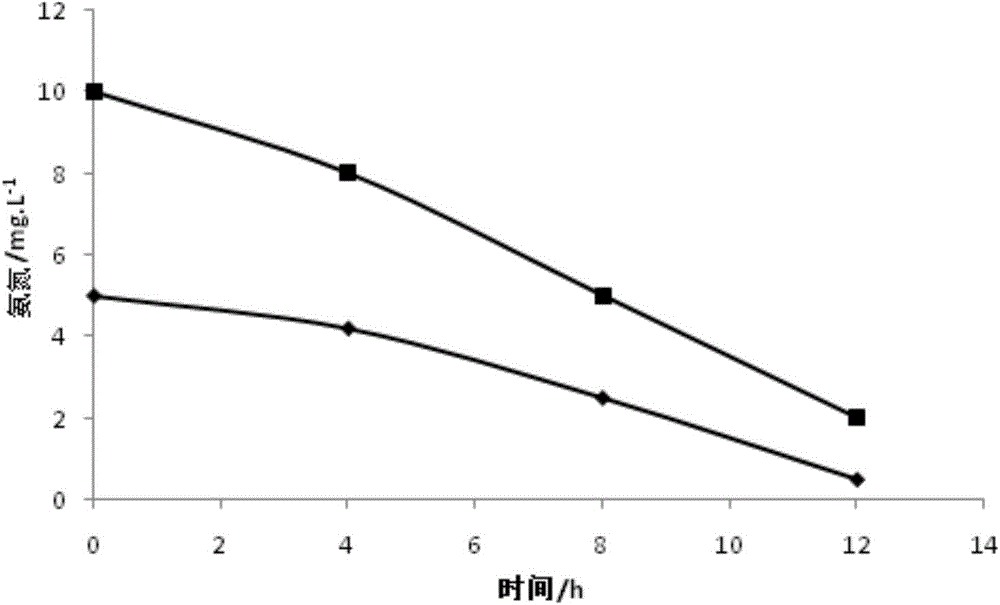

[0053] The concentration of total phosphorus in the influent is 1mg / L, the concentration of ammonia nitrogen in the influent is 5.4mg / L, the concentration of nitrate nitrogen is 10.8mg / L, and the COD is 52mg / L.

[0054] use as figure 1 Subsurface wetlands shown for water treatment, each zone 6m long, hydraulic retention time 4h per zone, hydraulic load 0.5-0.6m 3 / m 2 d. Among them, the amount of zeolite in the pre-treatment area is 0.1t, and the amount of steel slag is 0.8t; the amount of zeolite in the intermediate treatment area is 0.2t, and the amount of steel slag is 1.1t; the amount of zeolite in the post-treatment area is 0.225t, and the amount of steel slag is 0.175t. The porosity of the mixed filler is 35%.

[0055] After treatment, the concentration of total phosphorus in the effluent is 0.4mg / L, the concentration of nitrate nitrogen is 8.3mg / L, the concentration of ammonia nitrogen is 0.5mg / L, and the concentration of total nitrogen is 8.8mg / L.

Embodiment 3

[0057] Influent total phosphorus concentration is 1.45mg / L, influent ammonia nitrogen concentration is 9.5mg / L, nitrate nitrogen concentration is 15mg / L, and COD is 80mg / L.

[0058] use as figure 1 Subsurface wetlands shown for water treatment, each zone 6m long, hydraulic retention time 4h per zone, hydraulic load 0.5-0.6m 3 / m 2 d. Among them, the amount of zeolite in the pre-treatment area is 0.1t, and the amount of steel slag is 0.7t; the amount of zeolite in the intermediate treatment area is 0.18t, and the amount of steel slag is 1.1t; the amount of zeolite in the post-treatment area is 0.22t, and the amount of steel slag is 0.20t. The porosity of the mixed filler is 35%.

[0059] After treatment, the concentration of total phosphorus in the effluent is 0.5mg / L, the concentration of nitrate nitrogen is 9.8mg / L, the concentration of ammonia nitrogen is 1.7mg / L, and the concentration of total nitrogen is 11.5mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com