Production technology of nature-imitated stone material cast stone

A technology imitating natural stone and production technology, which is applied in the field of building materials, can solve the problems of increasing building weight, slow construction progress, and high difficulty, and achieve the effects of reducing over-exploitation, reducing maintenance costs, and uniform specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A. Mold making: produce corresponding molds according to the designed shape and pattern;

[0027] B. Mixing of raw materials, adding water and stirring:

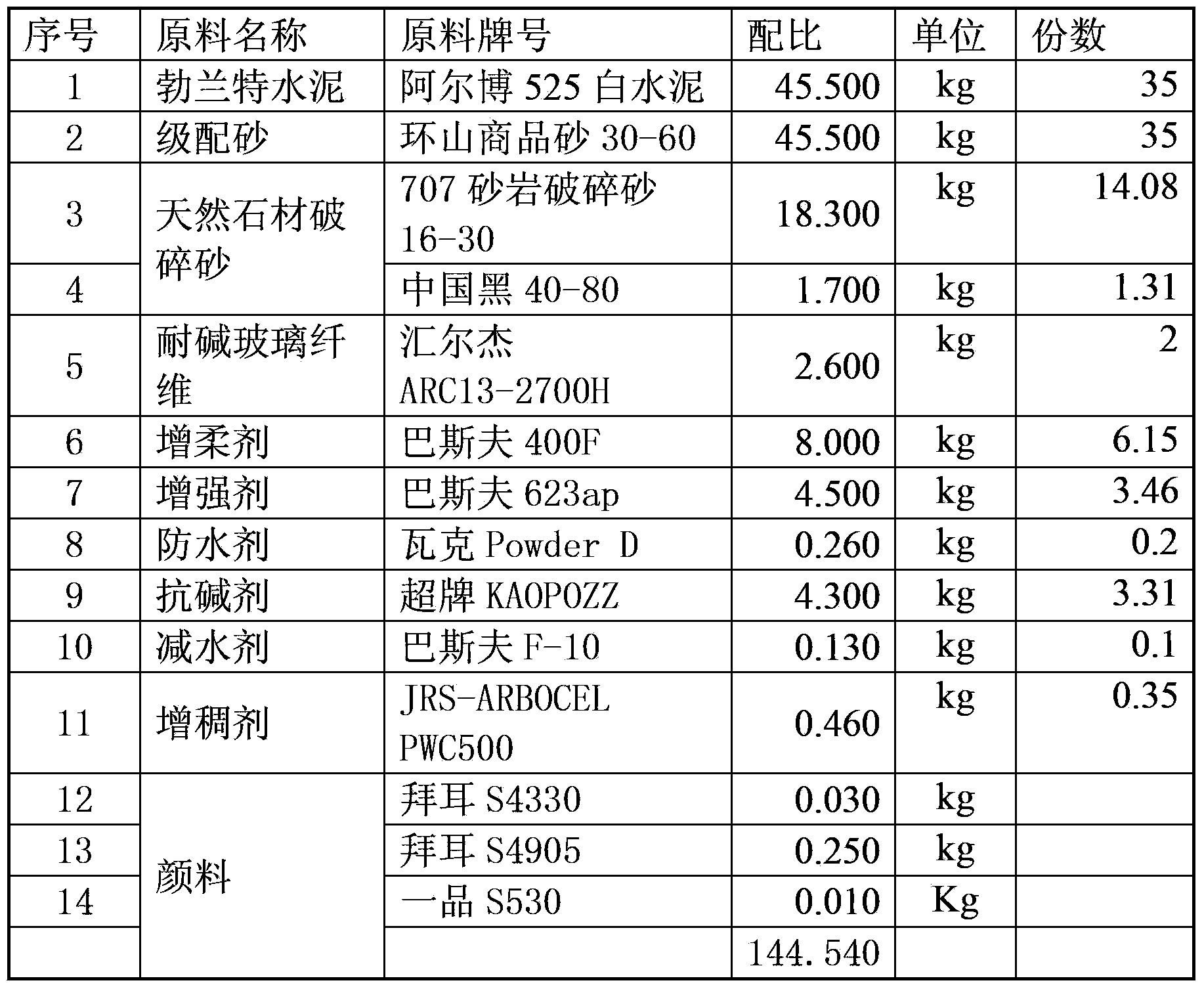

[0028] Put the following raw materials into the gravity mixer and mix them evenly.

[0029]

[0030] After mixing the above raw materials evenly, slowly add 13kg of water, and continue to stir evenly to make it into a slurry.

[0031] C. Infusion molding: Pour the uniformly stirred slurry in step B into the mold, and after the slurry is solidified and formed, demould and take out the semi-finished product;

[0032] D. Curing: send the semi-finished product obtained in step C into a closed space for curing; the temperature in the closed space is 25°C; the relative humidity is 90%.

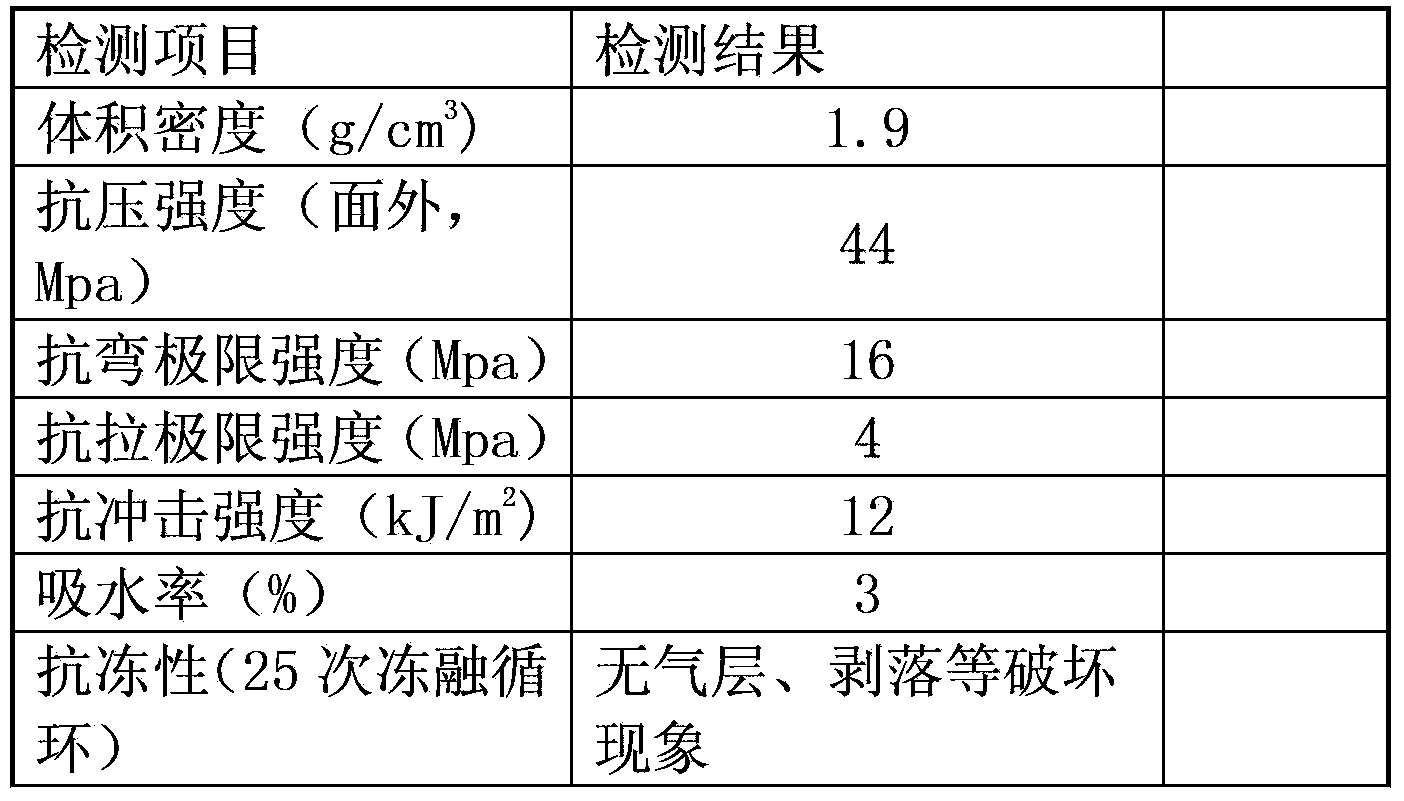

[0033] E. Shot blasting: After 10 days of maintenance in a closed space, put the semi-finished product into the shot blasting assembly line for shot blasting treatment, select 304 steel shots with a diameter of 0.5mm, and the speed of ...

Embodiment 2

[0041] A. Mold making: produce corresponding molds according to the designed shape and pattern;

[0042] B. Mixing of raw materials, adding water and stirring:

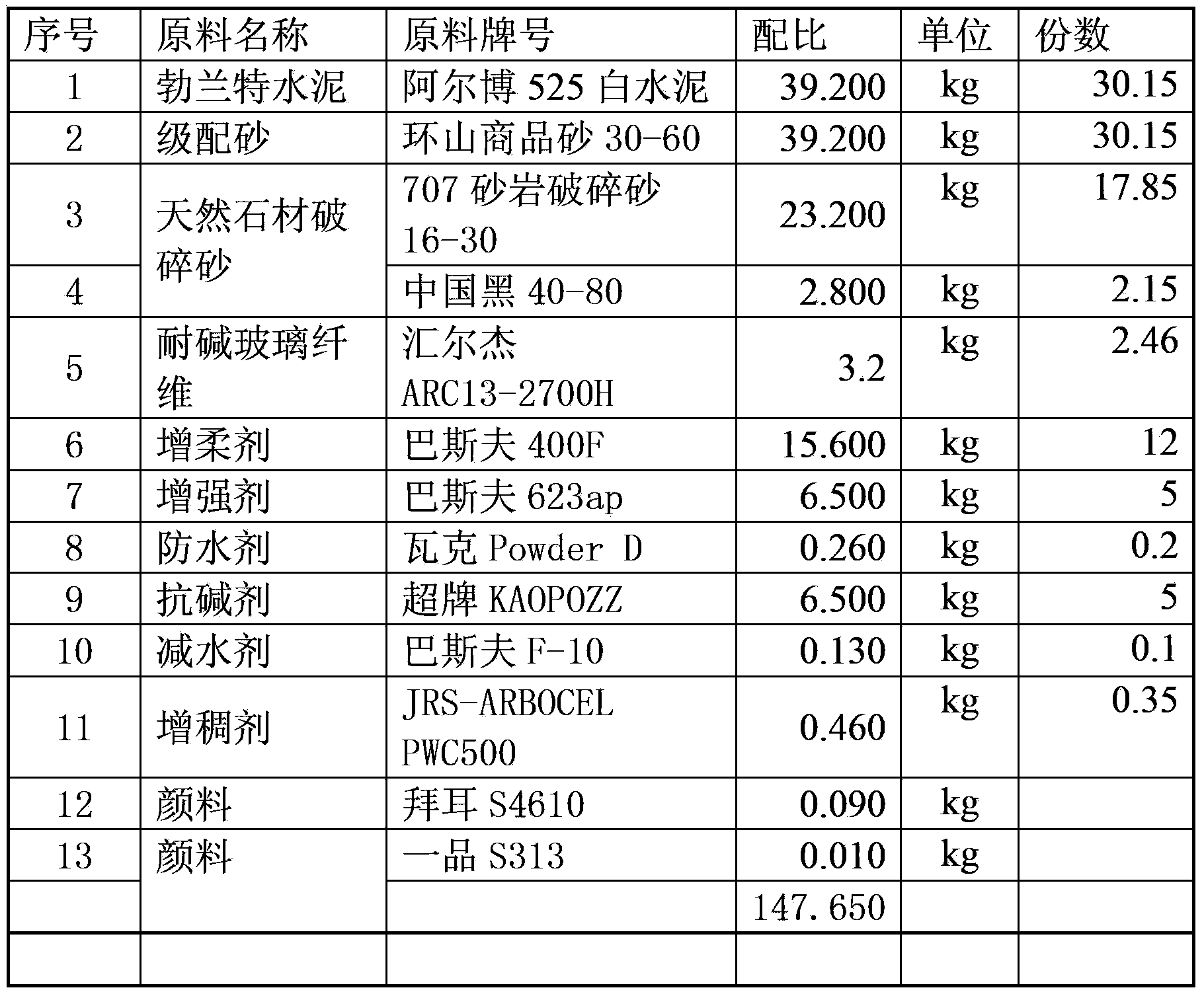

[0043] Put the following raw materials into the gravity mixer and mix them evenly.

[0044]

[0045] After mixing the above raw materials evenly, slowly add 10.5kg of water, and continue stirring evenly to make it into a slurry.

[0046]C. Infusion molding: Pour the uniformly stirred slurry in step B into the mold, and after the slurry is solidified and formed, demould and take out the semi-finished product;

[0047] D. Curing: Send the semi-finished product obtained in step C into a closed space for curing; the temperature in the closed space is 45°C; the relative humidity is 100%.

[0048] E. Shot blasting: After 6 days of maintenance in a closed space, put the semi-finished product into the shot blasting line for shot blasting treatment, select 304 steel shots with a diameter of 1.5mm, and the speed of the lin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com