Halogen-free flame retardant PVC (polyvinyl chloride) material for automobiles and preparation method of halogen-free flame retardant PVC material

A technology of PVC material and PVC resin, applied in the field of PVC material and its preparation, can solve the problems of non-compliance with safety and environmental protection, affecting human health, corrosive toxicity, etc., and achieve good environmental protection flame retardancy, good thermal stability, and flame retardancy. high level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

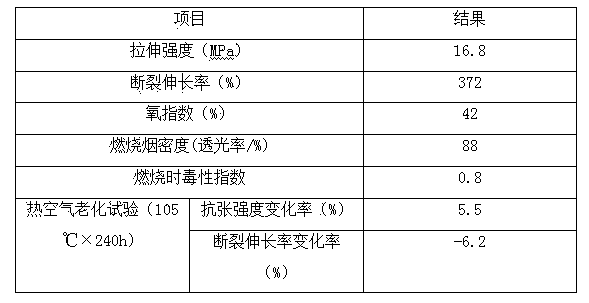

Image

Examples

Embodiment Construction

[0010] A halogen-free flame-retardant PVC material for automobiles, made of the following raw materials by weight (kg): SG-3 type PVC resin 50, bisphenol A type polycarbonate 30, polyphenylene ether 18, phenoxy polyphosphazene 12. Zinc molybdate 11, expanded graphite 14, magnesium hypophosphite 8, silicone grease 6, tris(hydroxyethanethiol) antimony 2.5, lead salicylate 2, stearyl benzoylmethane 2.5, dipentaerythritol Octanol ester 4, magnesium aluminum silicate 8, tourmaline powder 7, boehmite powder 12, cyclohydrogenated diisononyl phthalate 16, trimethylsilylmethyl phosphonate 8, acetyl citrate tri Hexyl ester 10, composite nanopowder 12, antioxidant 300 1.5, antioxidant 1010 1;

[0011] The preparation method of the composite nano-powder is as follows: a. Weigh wollastonite, medical stone and zeolite in a weight ratio of 5:3:2, mix uniformly, calcinate at 850°C for 2h, cool to room temperature, pulverize, sieve, Stand-by; b. Add 3 times the amount of 0.1mol / L Na to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com