Heavy aromatics lightened monolithic catalyst and preparation method thereof

A monolithic catalyst, a technology for lightening heavy aromatics, applied in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc. Complex, serious environmental pollution and other problems, to achieve the effect of ensuring hydrothermal stability, conducive to adsorption and diffusion, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

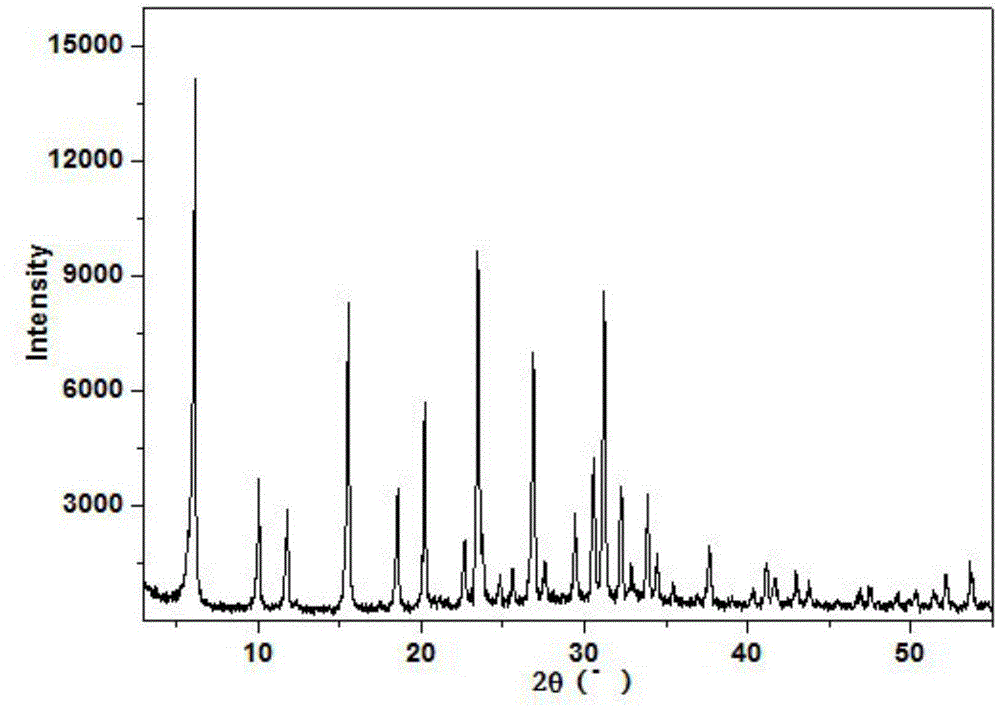

Image

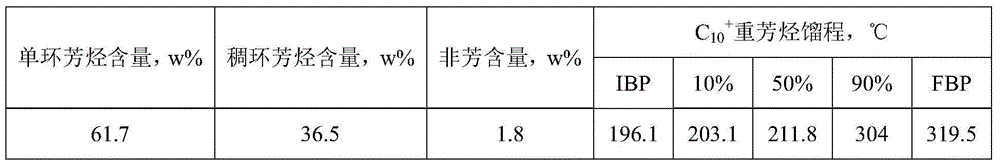

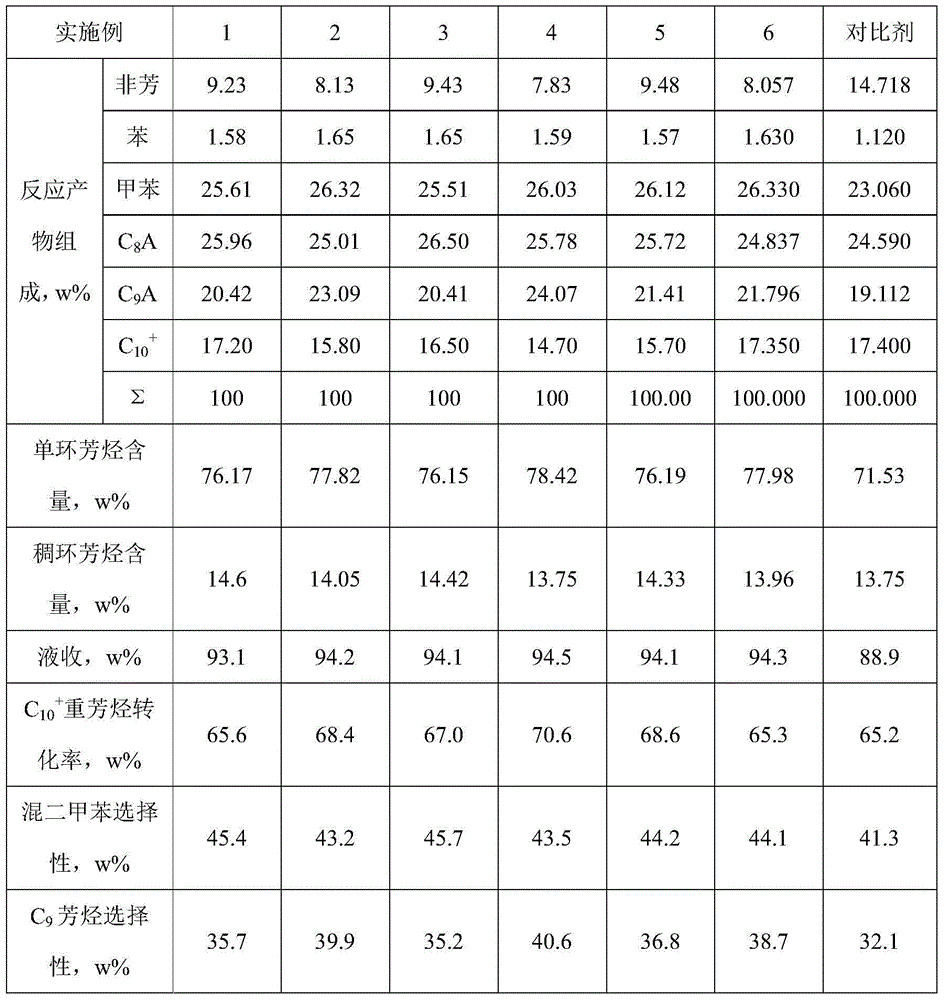

Examples

Embodiment 1

[0043] Put kaolin into a muffle furnace, raise the temperature to 650°C at a rate of 2°C / min, and calcinate at 650°C for 5 hours to obtain metakaolin.

[0044] Weigh 4.4 grams of white carbon black (SiO 2 Content 89.6wt%), 4 grams of metakaolin, 2.27 grams of sodium hydroxide, 0.66 grams of water glass, 0.85 grams of directing agent, 4.5 grams of deionized water and 0.5 grams of scallop powder are put into the sesame seed cake and stirred and kneaded until uniform wetting state, the kneaded material is extruded into a strip-shaped reaction substrate, and the mixture ratio is 1.8Na 2 O: Al 2 o 3 :6SiO2 2 :17.5H 2 O. Put 9 grams of the formed reaction substrate into a polytetrafluoroethylene reactor with a water jacket interlayer, add 3.6 grams of deionized water to the outer jacket, and the reaction kettle will be statically crystallized at 150 ° C, and the crystallization time is 12 hours . After the reaction is finished, NaY molecular sieves are obtained by washing, fi...

Embodiment 2

[0049] Put kaolin into a muffle furnace, raise the temperature to 650°C at a rate of 2°C / min, and calcinate at 650°C for 5 hours to obtain metakaolin.

[0050] Weigh 5.6 grams of white carbon black, 4 grams of metakaolin, 3.17 grams of sodium hydroxide, 0.66 grams of water glass, 1 gram of directing agent, 6.8 grams of deionized water and 0.5 grams of scallop powder, put them into the sesame cake, stir and knead until uniform Wet state, the kneaded material is extruded into a strip-shaped reaction substrate, and the mixture ratio is 2.4Na 2 O: Al 2 o 3 :7SiO 2 :25.2H 2 O. Put 9 grams of the formed reaction substrate into a polytetrafluoroethylene reactor with a water jacket, add 3.6 grams of deionized water to the jacket, and statically crystallize the reactor at 140°C for 18 hours . After the reaction is finished, NaY molecular sieves are obtained by washing, filtering and drying.

[0051] The monolithic NaY molecular sieve is subjected to ammonium exchange according t...

Embodiment 3

[0055] Put kaolin into a muffle furnace, raise the temperature to 550°C at a rate of 2°C / min, and calcinate at 550°C for 6 hours to obtain metakaolin.

[0056] Weigh 6.65 grams of white carbon black, 4 grams of metakaolin, 5 grams of sodium hydroxide, 0.66 grams of water glass, 1.2 grams of directing agent, 11.6 grams of deionized water and 0.5 grams of scallop powder, put them into the sesame seed cake, stir and knead until uniform Wet state, the kneaded material is extruded into a strip-shaped reaction substrate, and the mixture ratio is 3.7Na 2 O: Al 2 o 3 :8SiO2 2 :40.7H 2 O. Put 9 grams of the formed reaction substrate into a polytetrafluoroethylene reactor with a water jacket interlayer, add 3 grams of deionized water to the outer jacket, and the reactor will be statically crystallized at 120 ° C, and the crystallization time is 24 hours . After the reaction is finished, NaY molecular sieves are obtained by washing, filtering and drying.

[0057] The monolithic Na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com