Rare/precious metal turning material cleaning process

A technology of rare and precious metals and metal turning, applied in cleaning methods and utensils, removal of solid waste, cleaning methods using liquids, etc., can solve problems such as ineffective use of rare and precious metals, waste of resources, etc., to improve operating efficiency and protect environment, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1, rare precious metal turning material cleaning process

[0073]Referring to accompanying drawing, working process of the present invention is:

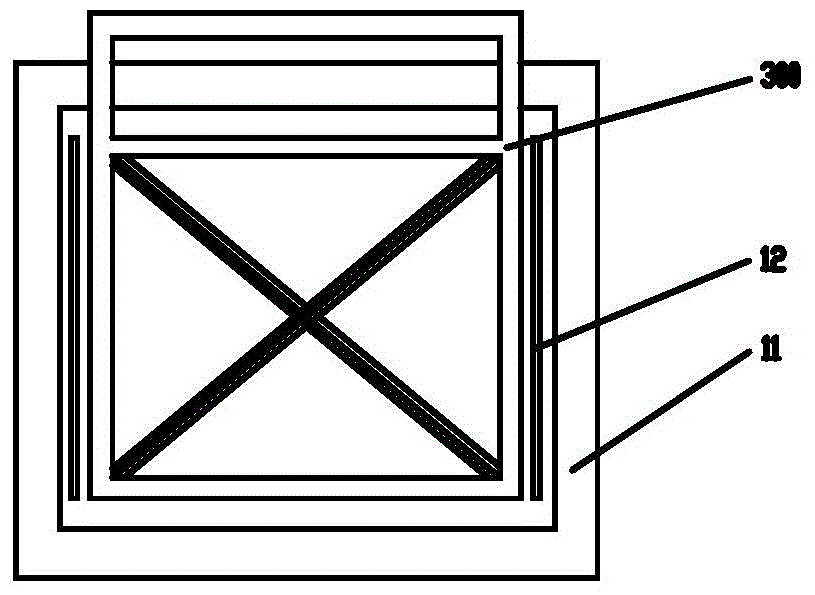

[0074] A, magnetic separation and impurity removal: take the metal turning material and put it into the magnetic separation device 2 after crushing to remove some magnetic impurities, then put the metal turning material into the operation material basket 100, and each operation material basket 100 is loaded with 10-15 kilograms; In this step, the stepping manipulator 200 is consistent with the stepping conveyor belt, stepping once every 80s on average;

[0075] B. Wind blowing and impurity removal: put the operation material basket 100 carrying the metal turning material on the starting end of the stepping conveyor belt, and when the operation material basket 100 travels to the end of the stepping conveyor belt, the stepping robot hand 200 grasps the operation material basket 100 into the air-blowing cleaning tank...

Embodiment 2

[0089] Embodiment 2, the special device of cleaning process

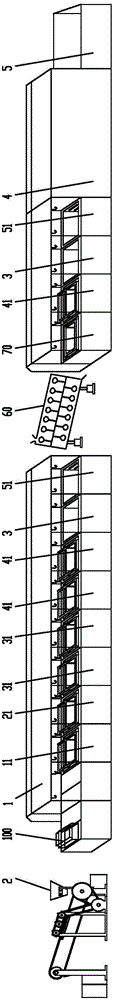

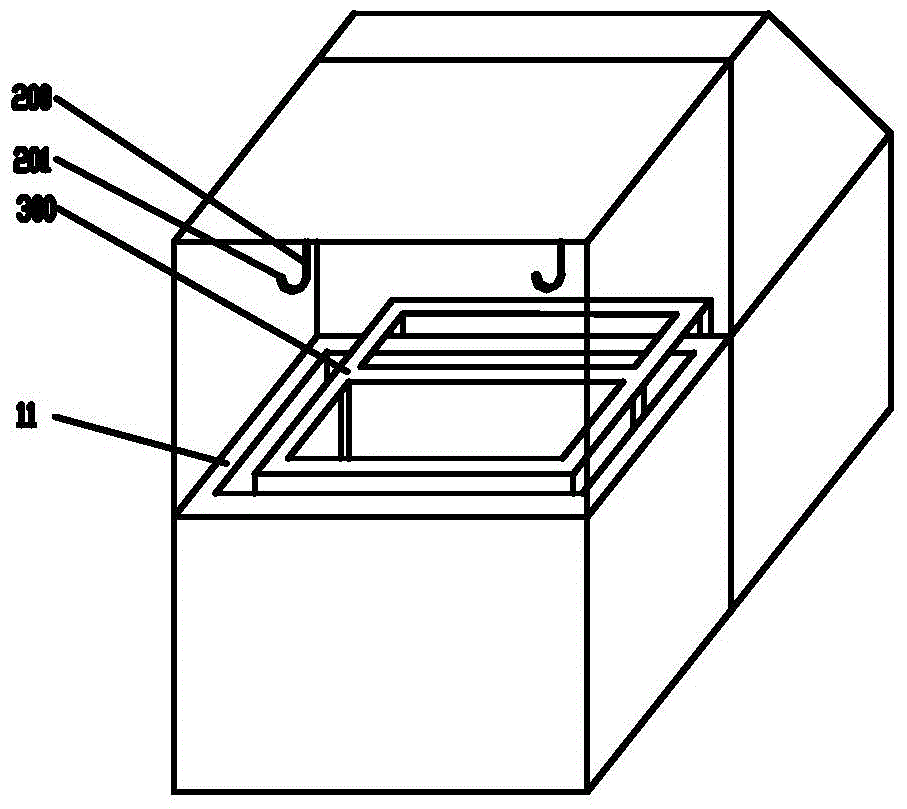

[0090] Referring to the accompanying drawings, the special device of the present invention includes a magnetic separation device 2, a cleaning and drying assembly, a sand washing and drying assembly, and a receiving device 5 in sequence according to the sequence of flow operation; Miscellaneous wind-blown cleaning tank 11, spray cleaning tank 21 for removing impurities by water washing, at least one set of lye ultrasonic cleaning tank 31, at least one set of bubbling cleaning tank 41, using gravity for natural dehydration and drying Drying tank 3 and the wind-cutting drying tank 51 that utilizes wind blowing to dry; the sand washing and drying assembly is arranged at the lower station of the cleaning and drying assembly, which successively includes a three-dimensional rolling sand washing device 60, a separation sand sand material separation device 70, at least one group of bubbling cleaning tanks 41, wind-cutting d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com