A kind of treatment method of ethylene oxychlorination process vinyl chloride production wastewater

A technology of ethylene oxychlorination and treatment methods, which is applied in natural water treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., to achieve stable and reliable treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

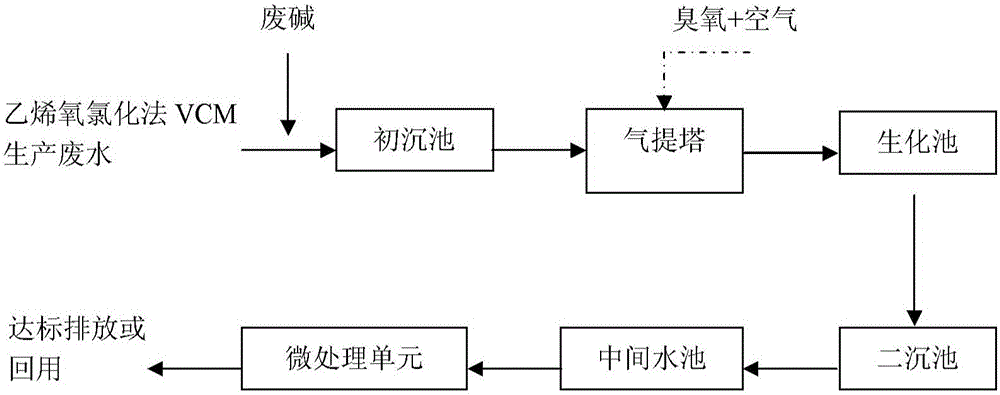

Image

Examples

Embodiment 1

[0026] What this embodiment handles is the VCM waste water discharged from the bottom of the quench tower tower of the ethylene oxychlorination unit, wherein COD Cr is 3680mg / L, and the copper ion concentration is 3.5mg / L. The specific treatment steps are as follows: the wastewater first adds alkali to adjust the pH value to 8-9, and after the flocculation and sedimentation in the primary sedimentation tank, the wastewater COD Cr Reduced to 3000-3300mg / L, the copper ion concentration is lower than 1mg / L. The effluent from the primary sedimentation tank enters the 2 / AC Catalyst Stripper. The waste water in the stripping tower is from top to bottom, and the mixed stripping medium of ozone and air is from bottom to top, and the ozone concentration is 25-30mg / L. Wastewater COD after the double effect of air stripping and ozone catalytic oxidation Cr down to 200-250mg / L. After heat exchange, the effluent water of the stripping tower enters the contact oxidation tank after the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com