A method of atom transfer radical polymerization based on liquid/liquid two-phase catalytic system

A catalytic system and atom transfer technology, applied in the field of catalytic polymerization, can solve the problems of high cost, time-consuming and laborious, and large-scale application limitations, and achieve the effects of simple operation, reduced metal salt residue, and strong designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

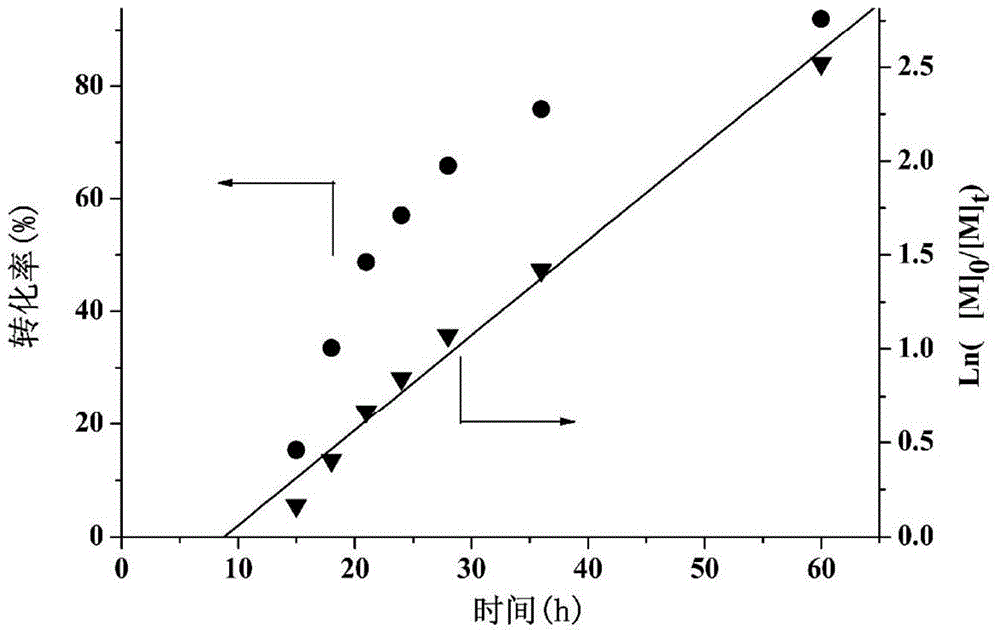

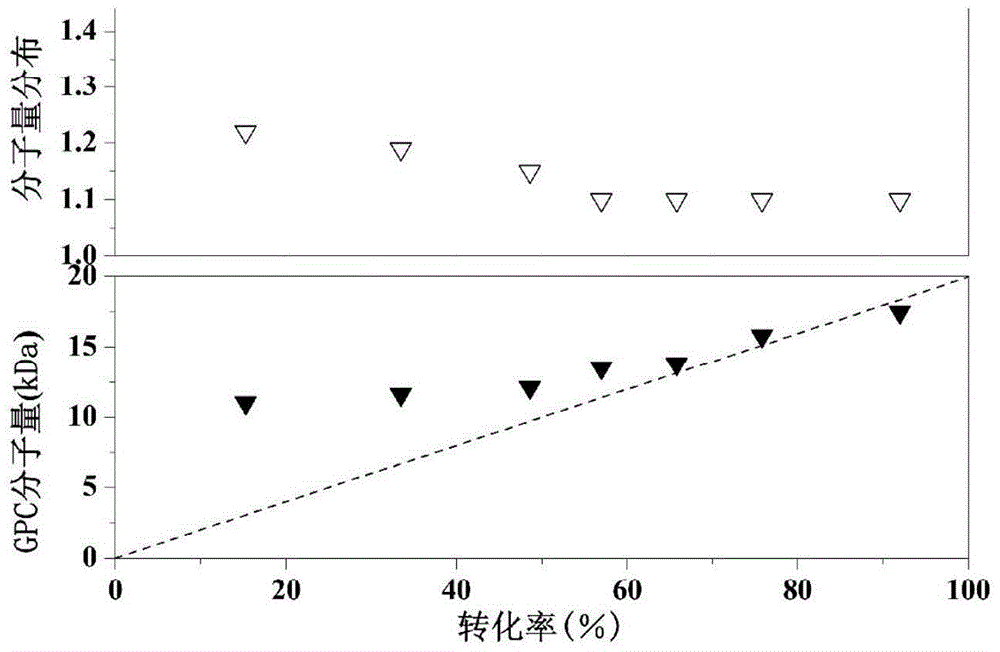

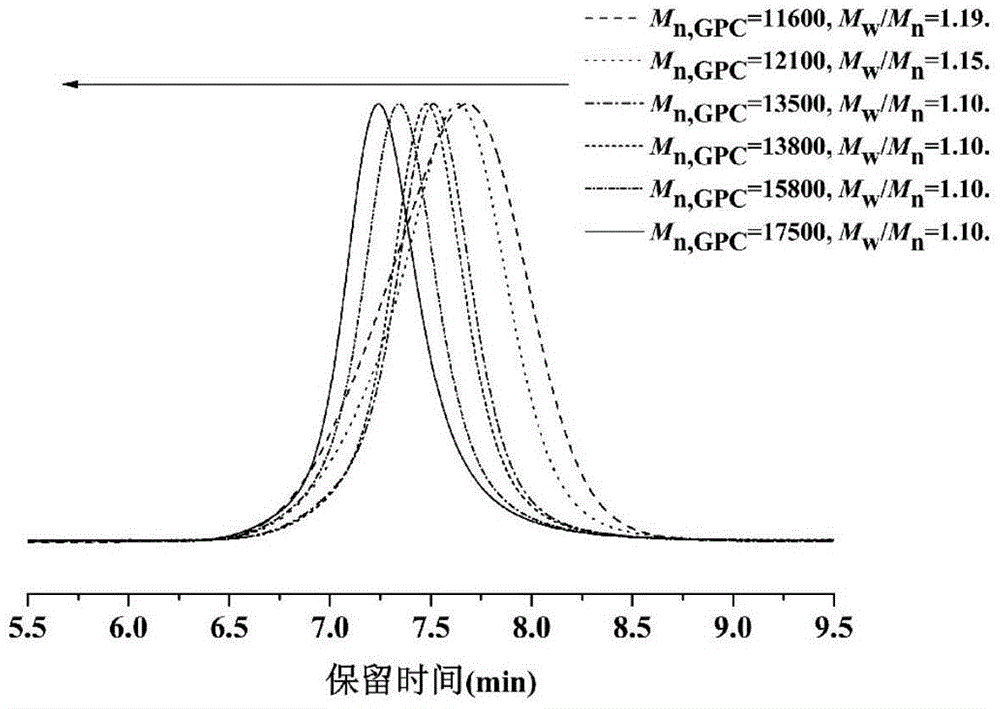

[0043] Example 1: MMA aggregation based on liquid / liquid -based two -phase catalytic system.

[0044] In N 单体 : n 引发剂 : n 催化剂 : n 配体 : n 还原剂 = 200: 1: 2: 2: 0.2 Initial Murbi, the single MMA (1.0 ml, 9.44 mmol), the induced agent EBRPA (8.25 μL, 0.0472 mmol), the reducing agent AIBN (1.55 mg, 9.44 × 10 10 -3 mmol) Add to 2 mL toluene, and catalyst CUBR 2 (21.2 mg, 0.0944 mmol), the ligand TPMA (27.4 mg, 0.0944 mmol) is added to 2 ml of pure water, and the two phases of water and organic solvents are mixed in the clean 10 ml amp bottle. You do not need to pass the oxygen removal operation.Tube.Then transfer the amaranth bottle to the set temperature (75 ° C) and the speed (1800 RPM) oil bath pot. After the given time (24 h), take it out and place it in the ice water to cool the layered, and thenThe upper layer is diluted with THF and poured into a large amount of methanol.

Embodiment 2

[0045] Example 2: MMA aggregation based on liquid / liquid -based two -phase catalytic system.

[0046] In N 单体 : n 引发剂 : n 催化剂 : n 配体 : n 还原剂 = 100: 1: 1: 1: 0.1 Initial Moore, the single MMA (0.5 ml, 4.72 mmol), the induction EBRPA (16.5 μL, 0.0944 mmol), the reducing agent AIBN (1.55 mg, 9.44 × 10 10 -3 mmol) Add to 1 mL toluene, and catalyst CUBR 2 (21.2 mg, 0.0944 mmol), the ligand TPMA (27.4 mg, 0.0944 mmol) is added to 3 ml of pure water, and the two phases of water and organic solvents are mixed in the clean 10 ml amp bottle. You do not need to pass the oxygen removal operation.Tube.Then transfer the amaranth bottle to the set temperature (90 ° C) and the speed (1600 RPM) oil bath pot. After the given time (30 h), take it out and place it in the ice water to cool the layered, and thenThe upper layer is diluted with THF and poured into a large amount of methanol.

Embodiment 3

[0047] Example 3: Different types of causes catalyzed the effects of ATRP on both phases of liquid / liquid.

[0048] For ATRP aggregation, especially the ATRP aggregation of oil -soluble monomers in the water phase, ATRP causes a very critical role. It can affect the efficiency, polymerization rate, and end functionalization of the polymer during the entire aggregation stage, etc.EssenceTo this end, we plan to use different causes of dictating agents such as 2-bromotoxylxate (EBIB), α-bromodybenzhenylene (EBRPA), 2-bromoopraceraceae(BPN), MPEG550-BR and other parallel preparation of a series of polymers to examine the effects of MMA aggregation under the catalytic system of liquid / liquid catalytic system for several conventional ATRP. The results are shown in Table 1 below.

[0049]

[0050] Polymerization: Except [MMA] 0 : [MPEG550-br] 0 = 100: 1, [mma] 0 : [Caused] 0 : [Cubr 2 ] 0 : [TPMA] 0 : [AIBN] 0 = 200: 1: 2: 2: 0.2, V MMA Intersection V 水 Intersection V 甲苯 = 1: 2: 2, t =...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com