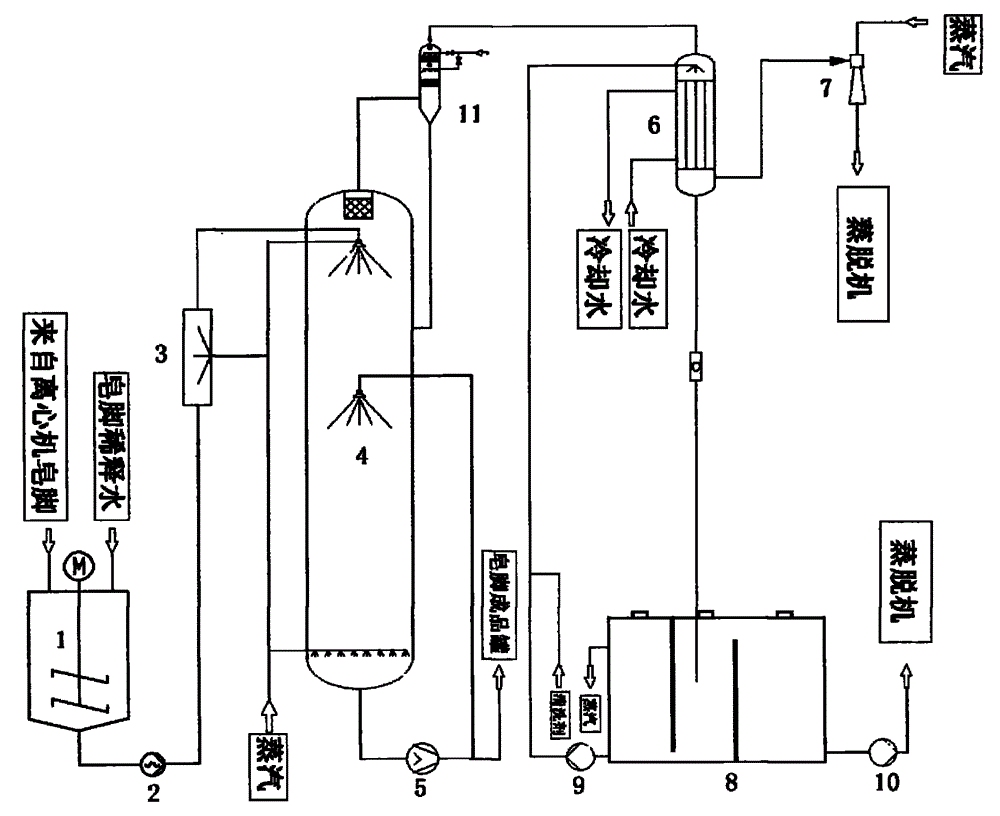

Two-stage efficient soapstock desolventizing system for mixed oil refinement

A technology of mixing oil and soapstock, which is applied in the field of oil processing, which can solve the problems of high steam consumption, more mechanical stirring, and increased solvent loss, etc., and achieve the effect of low steam consumption, less mechanical stirring, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Pre-vacuumize

[0043] Send steam into the steam jet vacuum pump 7 to discharge the air in the soapstock desolventization tank 4 until it reaches the designed vacuum degree.

[0044] 2), add a small amount of direct steam to the desolventization tank first, raise the temperature of the tank and further discharge the air, and then feed.

[0045] After pre-evacuation is completed, the soapstock delivery pump 2 is turned on to send the soapstock into the fast steam heater 3 to be heated to a certain temperature and then enter the soapstock precipitation tank 4.

[0046] 3) cycle

[0047] When the liquid level in the soapstock desolventization tank 4 reaches a certain level, the soapstock circulating pump 5 is opened, so that the soapstock forms an external circulation and enters the soapstock desolventization tank 4 again.

[0048] 4) Heating

[0049] Further open the valve of the directly heated steam at the bottom of the soapstock desolventization tank 4, adjust th...

Embodiment 2

[0055] 1) Pre-vacuumize

[0056] Send steam into the steam jet vacuum pump 7 to discharge the air in the soapstock desolventization tank 4 until it reaches the designed vacuum degree.

[0057] 2) Feeding

[0058] After completing the pre-vacuumization, start the soapstock delivery pump 2 to send the soapstock into the fast steam heater 3 to be heated to a certain temperature and then enter the soapstock precipitation tank 4.

[0059] 3) cycle

[0060] When the liquid level in the soapstock desolventization tank 4 reaches a certain level, the soapstock circulating pump 5 is opened, so that the soapstock forms an external circulation and enters the soapstock desolventization tank 4 again.

[0061] 4) Heating

[0062] Open the valve of the direct heating steam at the bottom of the soapstock desolventization tank 4, adjust the soapstock temperature in the tank to reach a certain desolventization temperature by controlling the opening of the valve, open the demister 11 to remove...

Embodiment 3

[0066] 1) Pre-vacuumize

[0067] Direct steam is passed into the soapstock desolventization tank, and the air in the soapstock desolventization tank 4 is discharged, and nitrogen replacement can also be used to discharge the air, and then steam is introduced.

[0068] 2) Feeding

[0069] Open the soapstock delivery pump 2 and send the soapstock into the fast steam heater 3 and enter the soapstock precipitation tank 4 after being heated to a certain temperature.

[0070] 3) cycle

[0071] When the liquid level in the soapstock desolventization tank 4 reaches a certain level, the soapstock circulating pump 5 is opened, so that the soapstock forms an external circulation and enters the soapstock desolventization tank 4 again.

[0072] 4) Heating

[0073] Further open the valve of the directly heated steam at the bottom of the soapstock desolventization tank 4, adjust the soapstock temperature in the tank to reach a certain desolventization temperature by controlling the openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com