Solid surface sizing agent for paper-making as well as preparation method and application thereof

A technology of solid surface and sizing agent, applied in papermaking, textiles, papermaking, paper coating, etc., can solve the problems such as the return of moisture to paper in summer, and achieve the effects of low cost, simple preparation method and fast curing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

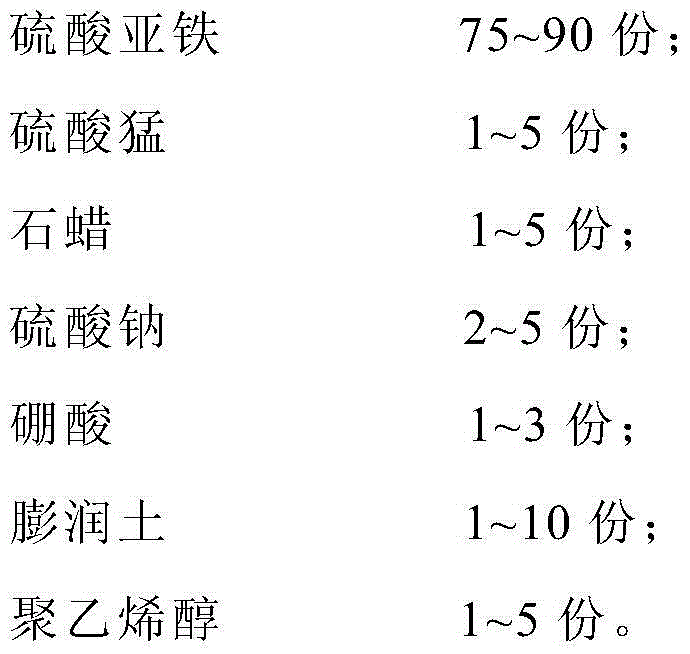

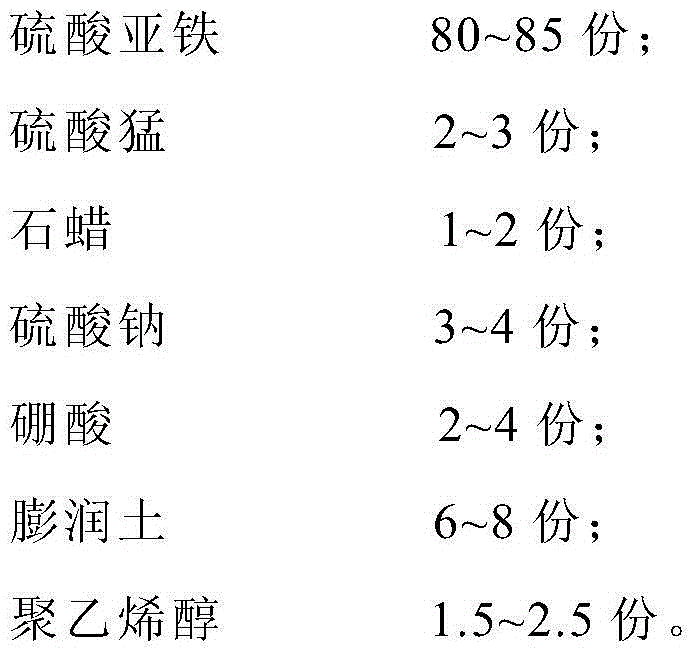

Method used

Image

Examples

Embodiment 1

[0024] 80 parts of ferrous sulfate, 3 parts of manganese sulfate, 2 parts of paraffin, 3 parts of sodium sulfate, 2 parts of boric acid, 6 parts of bentonite, and 2 parts of polyvinyl alcohol are put into the pulverizer and pulverized until all pass through a 60-mesh screen, and then Introduce the agitator and stir until the yellow-green powder is obtained to obtain the surface sizing agent.

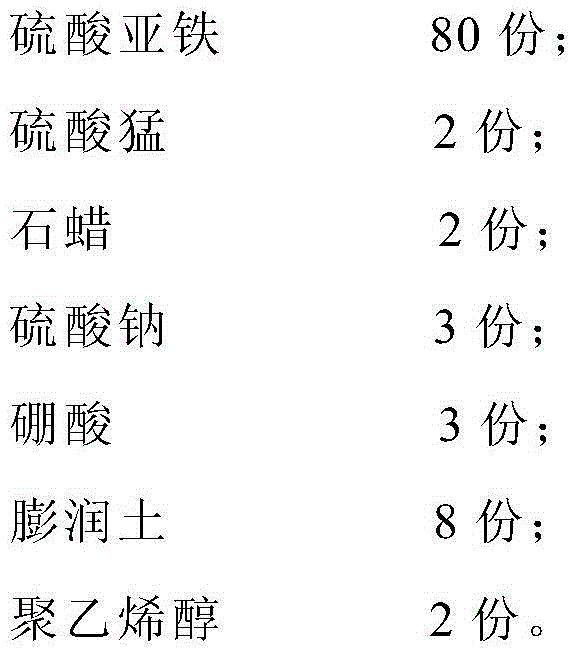

Embodiment 2

[0026] 80 parts of ferrous sulfate, 2 parts of manganese sulfate, 2 parts of paraffin, 3 parts of sodium sulfate, 3 parts of boric acid, 8 parts of bentonite, and 2 parts of polyvinyl alcohol are put into the pulverizer and pulverized until all pass through a 60-mesh screen, and then Introduce the agitator and stir until the yellow-green powder is obtained to obtain the surface sizing agent.

Embodiment 3

[0028] 83 parts of ferrous sulfate, 2 parts of manganese sulfate, 1 part of paraffin, 4 parts of sodium sulfate, 4 parts of boric acid, 6 parts of bentonite, and 2 parts of polyvinyl alcohol are put into the pulverizer and pulverized until all pass through a 60-mesh sieve, and then Introduce the agitator and stir until the yellow-green powder is obtained to obtain the surface sizing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com