High-precision automatic transistor test parameter acquisition system

An acquisition system and transistor technology, applied in thermometers, thermometers using electrical devices, and thermometers using directly heat-sensitive electric/magnetic components, can solve the problems of no R&D and production enterprises for transistor pressure and temperature automatic acquisition systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

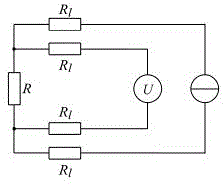

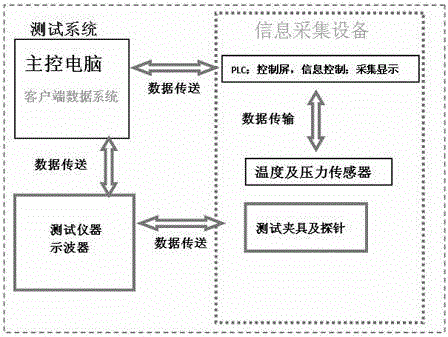

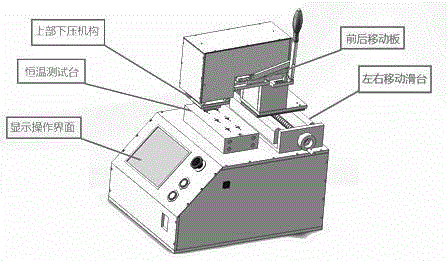

[0016] see Figure 1-5 , a high-precision automatic transistor temperature test and acquisition system, mainly used for temperature control of transistor thermal resistance test, mainly composed of servo motor force structure, test circuit, constant temperature cooling table, temperature and pressure sensor, information acquisition and comparison system 5 major components Partial composition, technical design scheme and implementation process of each part are described as follows:

[0017] 1) The force structure of the servo motor

[0018] The force-applying structure of the servo motor adopts a screw-type transmission mechanism, and the single-step movement stroke is controlled by PLC to achieve a high-precision pressing stroke, and the size of the pressing stroke is controlled according to the actual pressure demand. The contact surface between the pressure structure and the tested product is polyimide (PI), a thermal insulation material. PI is one of the organic polymer m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com