Pre-processing system and pre-processing method of trace moisture analysis in ultrahigh-purity gas

A pure gas, ultra-high technology, applied in the field of ultra-high-purity gas pretreatment, which can solve the problems of no ultra-high-purity gas available and unacceptable analysis time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

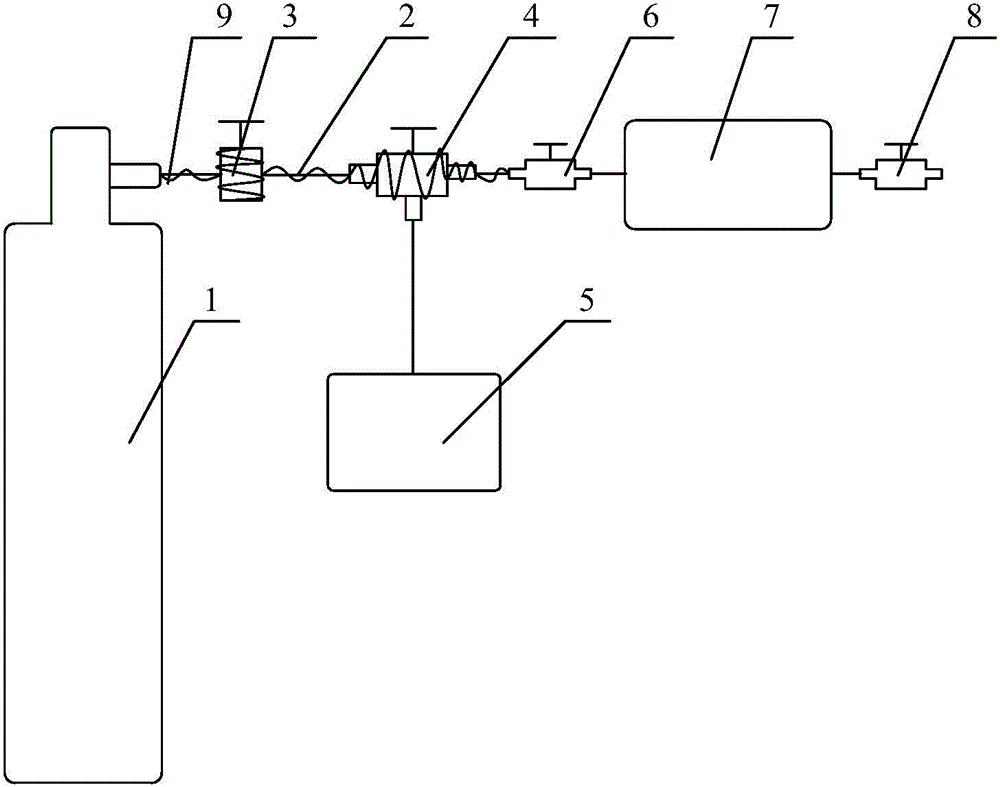

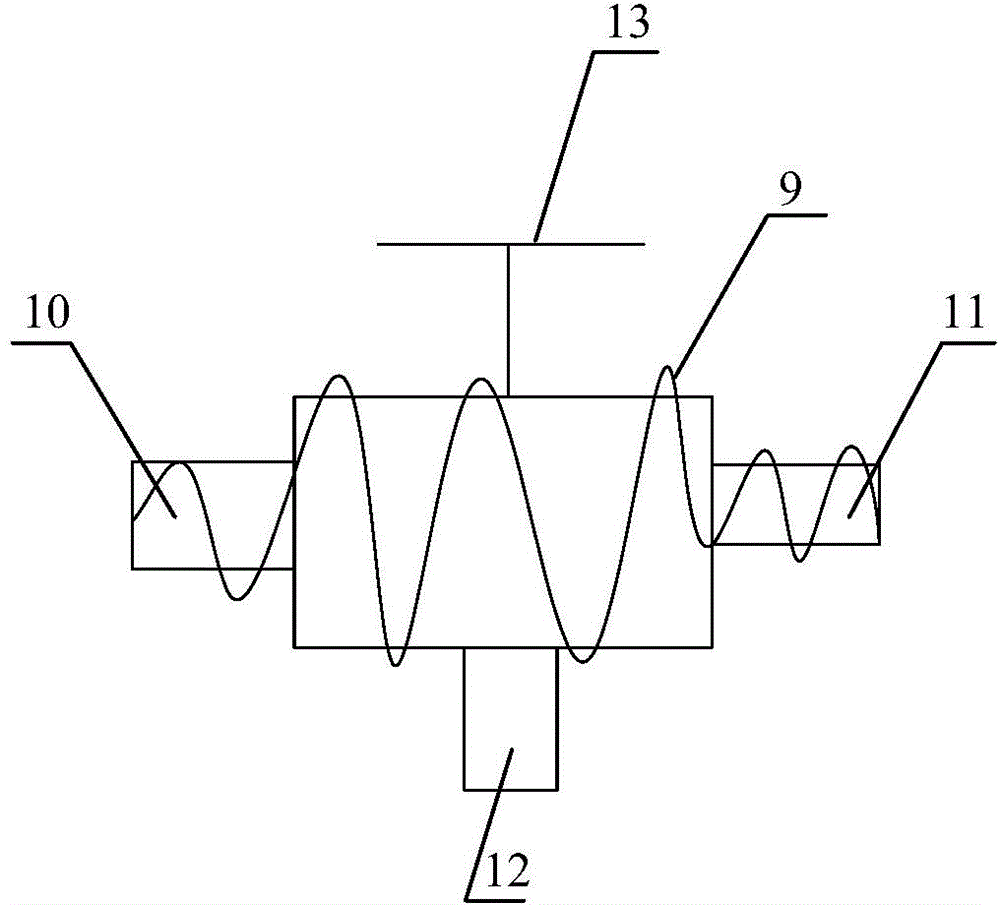

[0029] figure 1 It is a schematic diagram of the pretreatment system for analysis of trace moisture in ultra-high purity gas provided by the present invention. Depend on figure 1 As shown, the system includes an ultra-high-purity gas sample gas cylinder 1, a pressure reducing valve 3, a three-way flow valve 4, a first diaphragm valve 6 and The second diaphragm valve 8, wherein a trace moisture analyzer 7 is connected between the first diaphragm valve 6 and the second diaphragm valve 8. The first diaphragm valve 6 and the second diaphragm valve 8 mainly prevent the moisture in the environment from entering the trace moisture analyzer 7, and protect the trace moisture analyzer 7, and the structure of the diaphragm valve itself has small dead volume and airtightness nice features. In addition, a high-vacuum system 5 is connected to the port C12 of the three-way flow valve 4, and the high-vacuum system 5 performs high-vacuum treatment on the pipeline 2, the pressure reducing va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com