Compound microprobe for in-situ measurement of STM image and chloride ion concentration distribution and preparation method thereof

A technology for in-situ measurement of chloride ion concentration, applied in measurement devices, scanning probe technology, scanning probe microscopy, etc., to achieve the effects of high sensitivity, good practicability, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

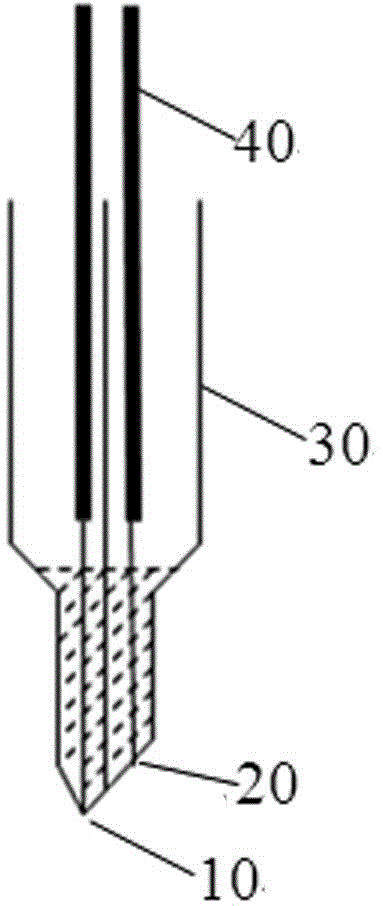

[0047] In the preparation process of the composite microprobe of the present invention, the characteristics of the glass tube to facilitate the drawing of small diameters are skillfully utilized, and the drawing method is used to prepare the glass capillary, and then the Pt wire and the Ag wire are put into the glass capillary, and the The tip of the Pt wire and Ag wire can be polished to a very small size, especially the tip of the Pt wire, so that the Pt wire has the characteristics of sensitive tunnel current, so as to realize the in-situ measurement of the metal surface STM image and chloride ion concentration distribution.

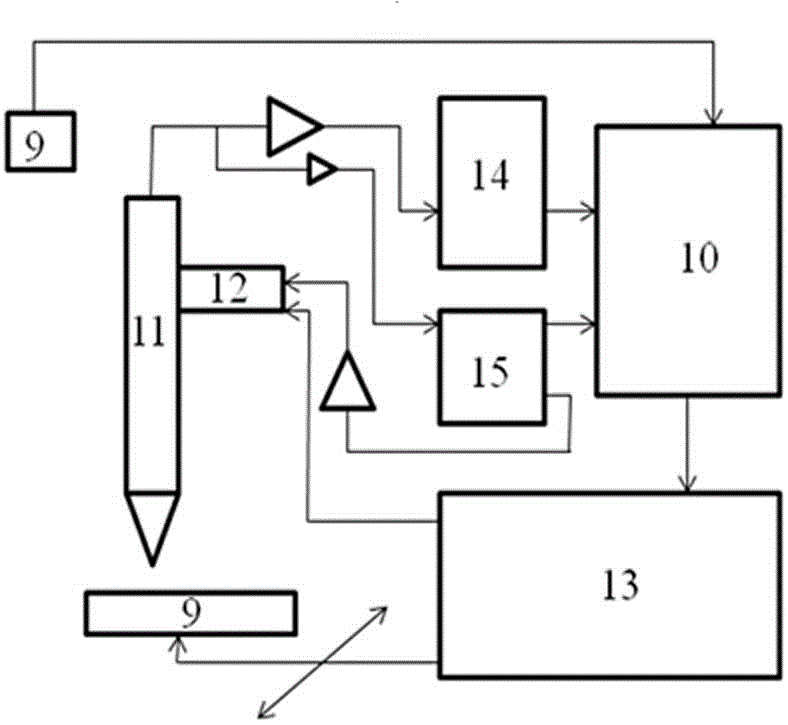

[0048] figure 2 The STM-assisted scanning microelectrode measurement system is shown, which consists of four parts: scanning tunneling microscope (STM) measurement platform; scanning microprobe and control / drive unit; tunnel current signal and micro-area potential signal measurement unit and measurement Signal control and processing unit. The STM m...

example 1

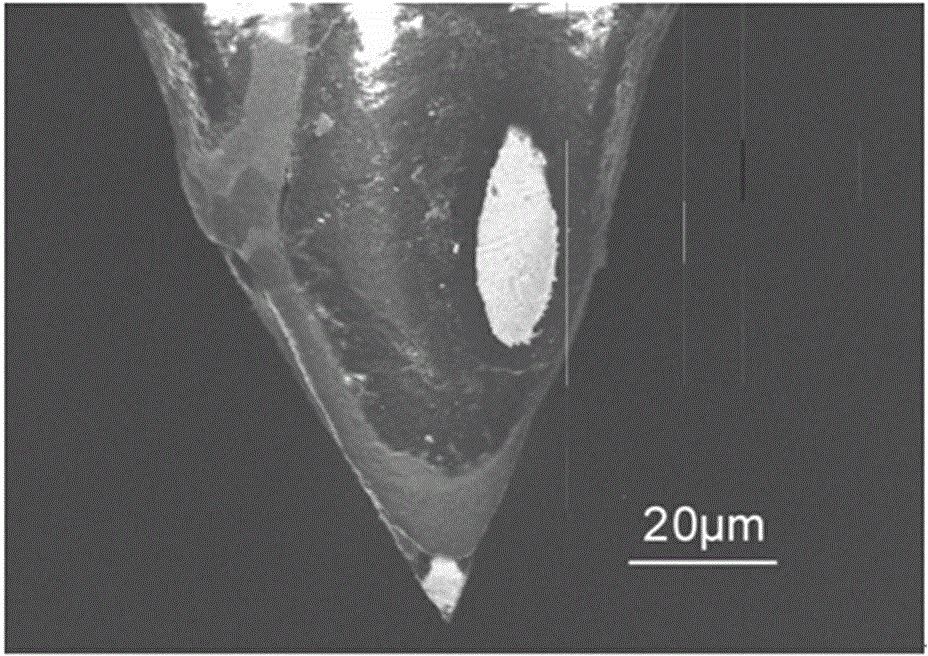

[0053] Take Pt wire (99.9% purity) and Ag wire (99.9% purity) with a cross-sectional diameter of 10 μm and a length of 3 cm and clean them; take a double-tube glass tube with a wall thickness of 100 μm between the two tubes, and use 30% The mixture of H2O2 and concentrated sulfuric acid in a ratio of 1:4 was cleaned and dried in an oven; the treated double-tube glass tube was stretched with a glass tube stretcher to prepare a glass containing two glass capillaries with a tip inner diameter of 10 μm tube; put Pt wire and Ag wire into the tips of two glass capillaries respectively, so that the tip positions are respectively encapsulated with a section of Pt wire and Ag wire, and encapsulated and fixed with epoxy resin, wherein the parallel distance between Pt wire and Ag wire is 30 μm ;After the resin is completely cured, the tip of the glass capillary is ground into a 30-degree cone surface by a glass grinder, so that the tips of the Pt wire and the Ag wire are fully exposed, an...

example 2

[0055] Take Pt wire (99.9% purity) and Ag wire (99.9% purity) with a cross-sectional diameter of 20 μm and a length of 4 cm and clean them; take a double-tube glass tube with a wall thickness of 150 μm between the two tubes, and use 30% H2O2 Wash the mixed solution mixed with concentrated sulfuric acid in a ratio of 1:4, and dry it in an oven; stretch the treated double-tube glass tube with a glass tube stretcher to prepare a glass tube containing two glass capillaries with a tip inner diameter of 10 μm ;Put the Pt wire and the Ag wire into the tip positions of two glass capillaries respectively, so that the tip positions are respectively encapsulated with a section of Pt wire and Ag wire, and encapsulated and fixed with epoxy resin, wherein the parallel distance between the Pt wire and the Ag wire is 40 μm; After the resin is completely cured, the tip of the glass capillary is ground into a cone with an angle of about 45 degrees by a glass grinder, so that the tips of the Pt w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tip diameter | aaaaa | aaaaa |

| Tip diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com