Femtosecond-laser and two-photon polymerization micro-nano machining system and method

A two-photon polymerization, femtosecond laser technology, applied in microlithography exposure equipment, optics, optomechanical equipment, etc., can solve the problem of limited improvement in processing efficiency of three-dimensional micro-nano devices, high difficulty in mass production of three-dimensional micro-nano devices, displacement In order to improve the processing efficiency and process flow, reduce the positioning accuracy requirements, and simplify the processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

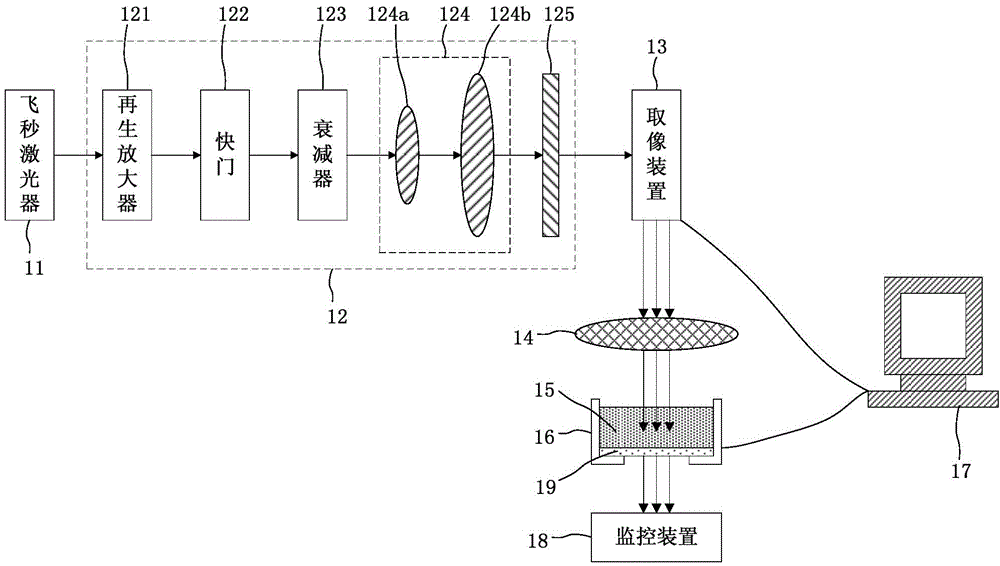

[0042] Embodiment 1 of the present invention provides a femtosecond laser two-photon polymerization micro-nano processing system. figure 1 It is a schematic structural diagram of a femtosecond laser two-photon polymerization micro-nano processing system provided in Embodiment 1 of the present invention. Such as figure 1As shown, the femtosecond laser two-photon polymerization micro-nano processing system includes: femtosecond laser 11, used to generate femtosecond laser; external optical path modulation unit 12, used to modulate the femtosecond laser; image taking device 13 , for taking images of the cross-sectional patterns of the three-dimensional micro-nano device layer by layer, so that the modulated femtosecond laser forms parallel beams arranged according to the cross-sectional patterns of each layer; the focusing lens 14 is used for The parallel light beams arranged in the cross-sectional pattern are respectively focused in the photosensitive material 15 to form a plan...

Embodiment 2

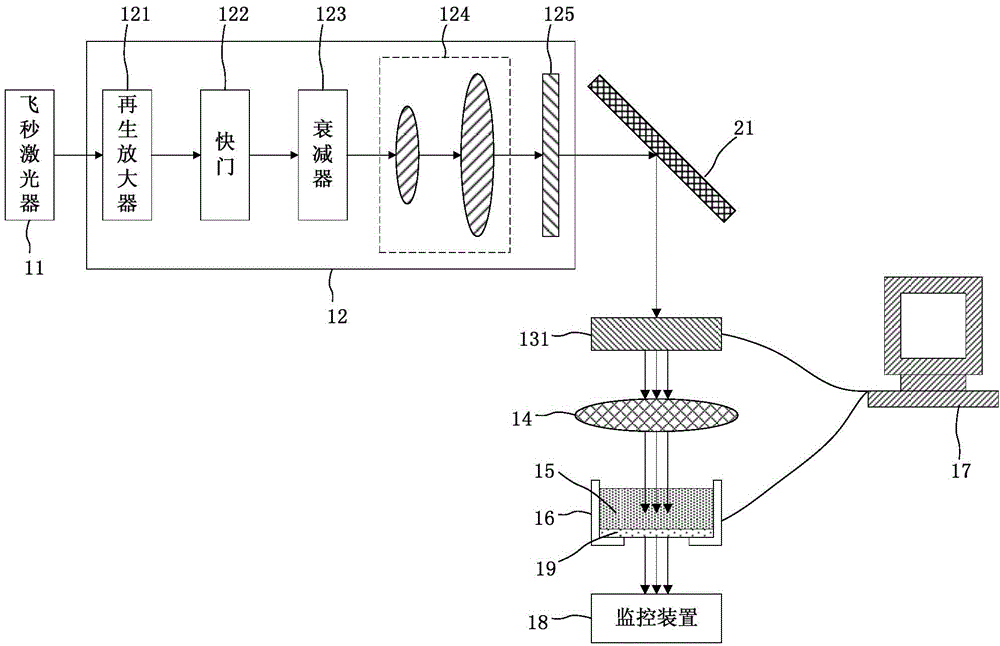

[0050] Embodiment 2 of the present invention also provides a femtosecond laser two-photon polymerization micro-nano processing system. On the basis of the first embodiment, the imaging device of this embodiment adopts a dynamic imaging device.

[0051] In this embodiment, the computer 17 is used to control the imaging device, including: the computer is used to model the structure of the three-dimensional micro-nano device, and convert the model obtained by modeling into The digital voltage signal is loaded on the dynamic imaging device to form cross-sectional patterns of each layer of the three-dimensional micro-nano device on the dynamic imaging device. Specifically, the computer 17 can carry out computer-aided design through the software control unit in it, establish a three-dimensional model for the three-dimensional micro-nano device to be processed, divide the built three-dimensional model into multi-layer cross-sectional graphics, and then divide each layer of cross-sect...

Embodiment 3

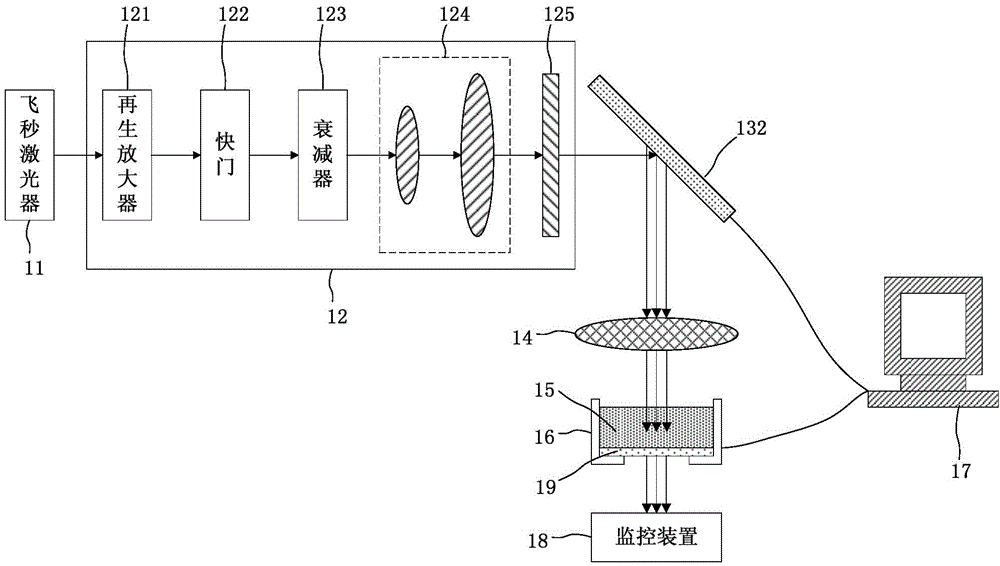

[0068] Embodiment 3 of the present invention also provides a femtosecond laser two-photon polymerization micro-nano processing system. Different from the second embodiment, the imaging device of this embodiment adopts a static imaging device.

[0069] Further, the static imaging device may use a mask. Figure 4 It is a schematic structural diagram of a femtosecond laser two-photon polymerization micro-nano processing system provided in Embodiment 3 of the present invention. Such as Figure 4 As shown, the static imaging device adopts a mask plate 133, and in order to make the structure of the whole micro-nano processing system more compact, it is set on the advancing path of the femtosecond laser and between the aperture stop 125 and the mask plate 133 imaging device 13 A total reflection mirror 21 is provided.

[0070] In this embodiment, preferably, the mask plate 133 includes a plurality of micro-regions, and each micro-region includes a layer of cross-sectional pattern ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com